5-66

MAINTENANCE

EVERY 4000 HOURS

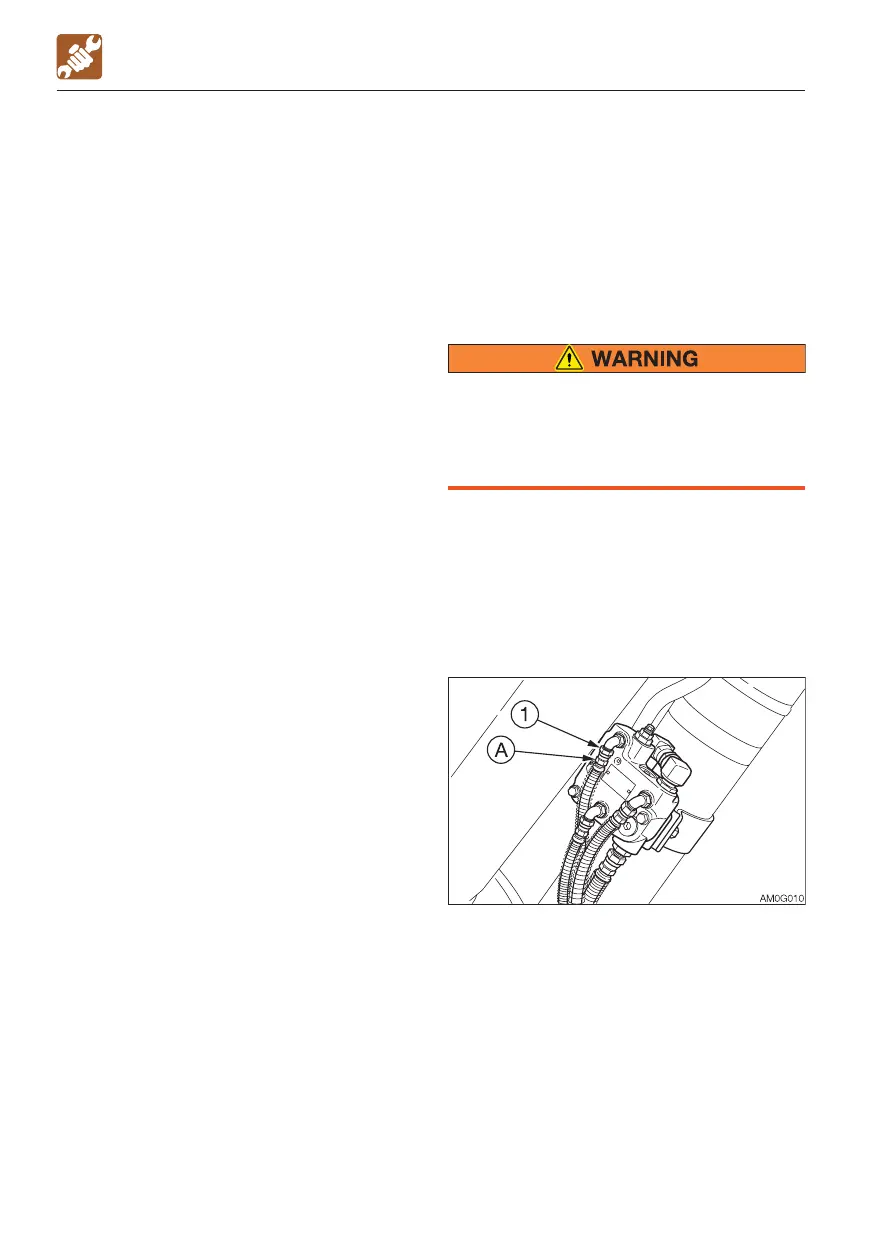

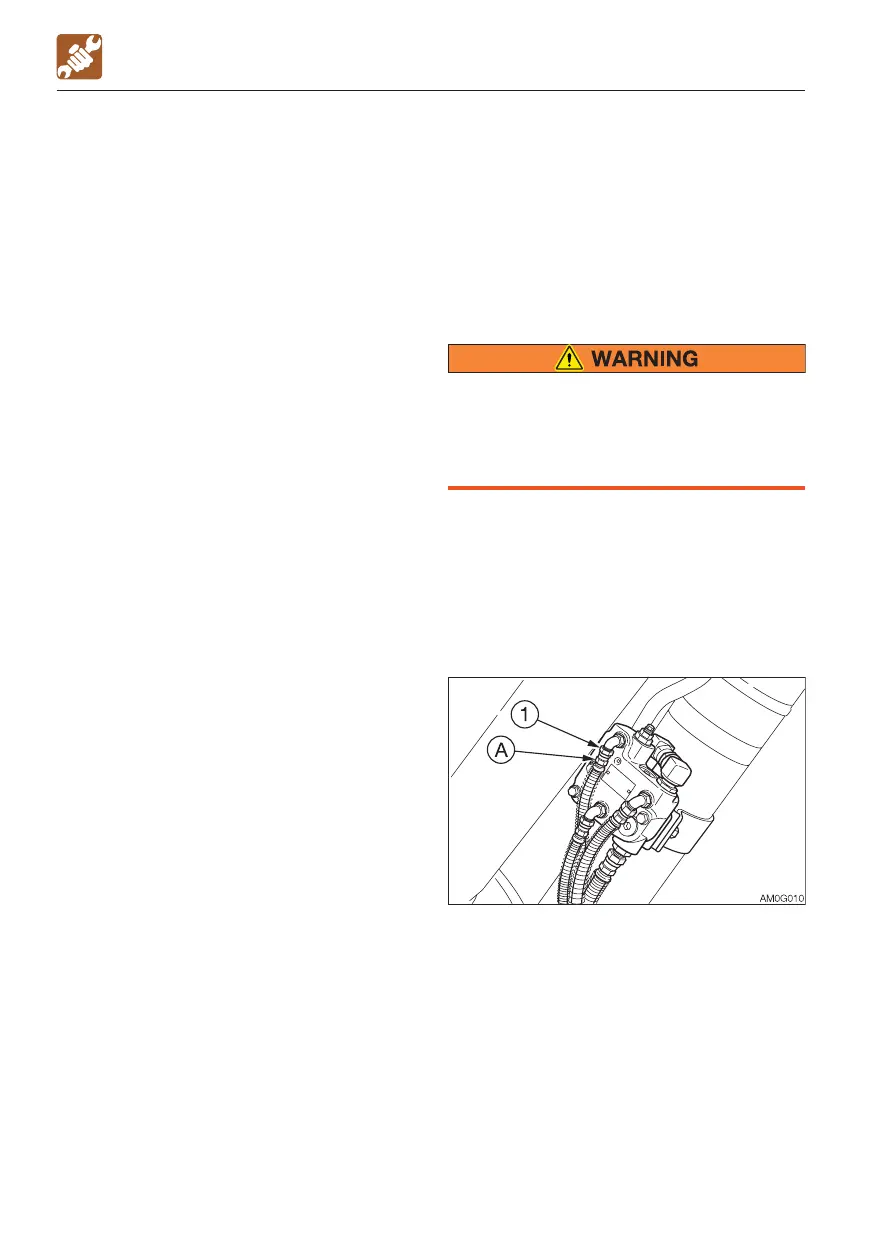

4. Hold the hose fitting (A) in place with a

wrench and slowly loosen the hose nut (1).

5. Slowly move the boom in the “Boom

lower” direction a little until there are no

more air bubbles coming from the hose

nut (1) joint.

6. Hold the hose fitting (A) in place with a

wrench and tighten the hose nut (1).

• Emergency shut-off valve

This operation is dangerous and requires

experience. Ask your sales or service dealer

for help.

If air is not released, the working equipment

could become slow in reacting to the

operation of the operator and show

unexpected behavior.

When removing plugs or screws, or when

disconnecting hoses, stand to the side

and loosen them slowly to gradually

release the internal pressure before

removing.

1. Place a pan under the hose (A) or (B) to

catch the waste oil.

2. Start the engine and run it at low idle.

3. Fully lower the safety lock lever to the

unlock position.

Boom

• Cylinders

1. Start the engine, let it run at a low-idling

speed for 10 minutes.

2. Maintain the engine at low idle, and then

slowly extend and retract each cylinder 4

or 5 times, without letting them reach the

stroke end.

3. While running the engine at high speed,

slowly extend and retract each cylinder 4

or 5 times, without letting them reach the

stroke end.

4. Return the engine speed to low idle, and

then slowly extend and retract each

cylinder 4 or 5 times to the stroke end.

Loading...

Loading...