9

6.3.2 MOUNT WHEEL

Preparation before test:Check and clean the dust and

mud and if there are foreign bodies, such as metal and

stone, clipped on the surface of the tire. And also check

the air pressure of the tire is according with the

specified value. Check if there are deformation on the

rim positioning surface and installation hole.

Check if there are any foreign bodies in the tire. Take

off the original weight.

The installation methods of the wheel : Positive

positioning, negative positioning & flange disk when

handling the middle and big sizes of tires. You can

select the methods according to the different

conditions.

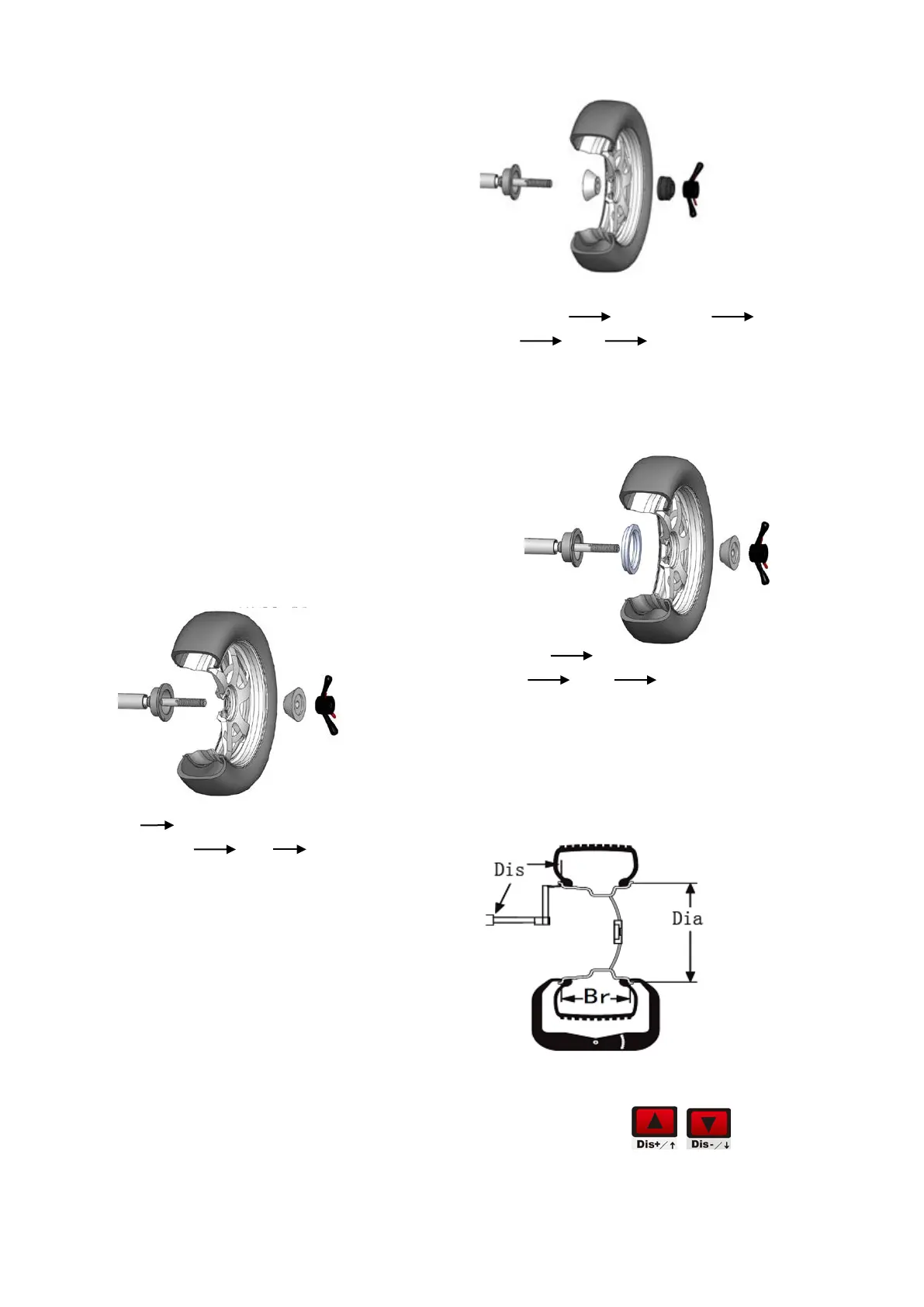

6.3.2.1 SMALL CAR WHEEL POSITIVE POSITION

Positive positioning is the normal method. It is featured

with simple and quick operation. It is mainly suitable to

the common steel rim and aluminum alloy rim with

small deformation.

Main shaft wheel(direction of the rim installation

surface is inside) cone quick nut

6.3.2.2

When the deformation of the outside of the wheel,

adopt this method to positioning to grantee the

accurate positioning of the steel rim inner hole and

main shaft. It is suitable to the steel rim, especially the

thick ALU

Main shaft lower spring suitable cone

wheel bowl quick nut

6.3.2.3 FLANGE DISK POSITIONING(OPTIONAL)

Suitable to the big tire assemble

Main shaft flange disk(fixed on the main shaft)

wheel cone quick nut

NOTE: The choice on the cone should be adapted

to the rim center hole and pay attention to its direction.

Or it will cause the inaccurate measurement.

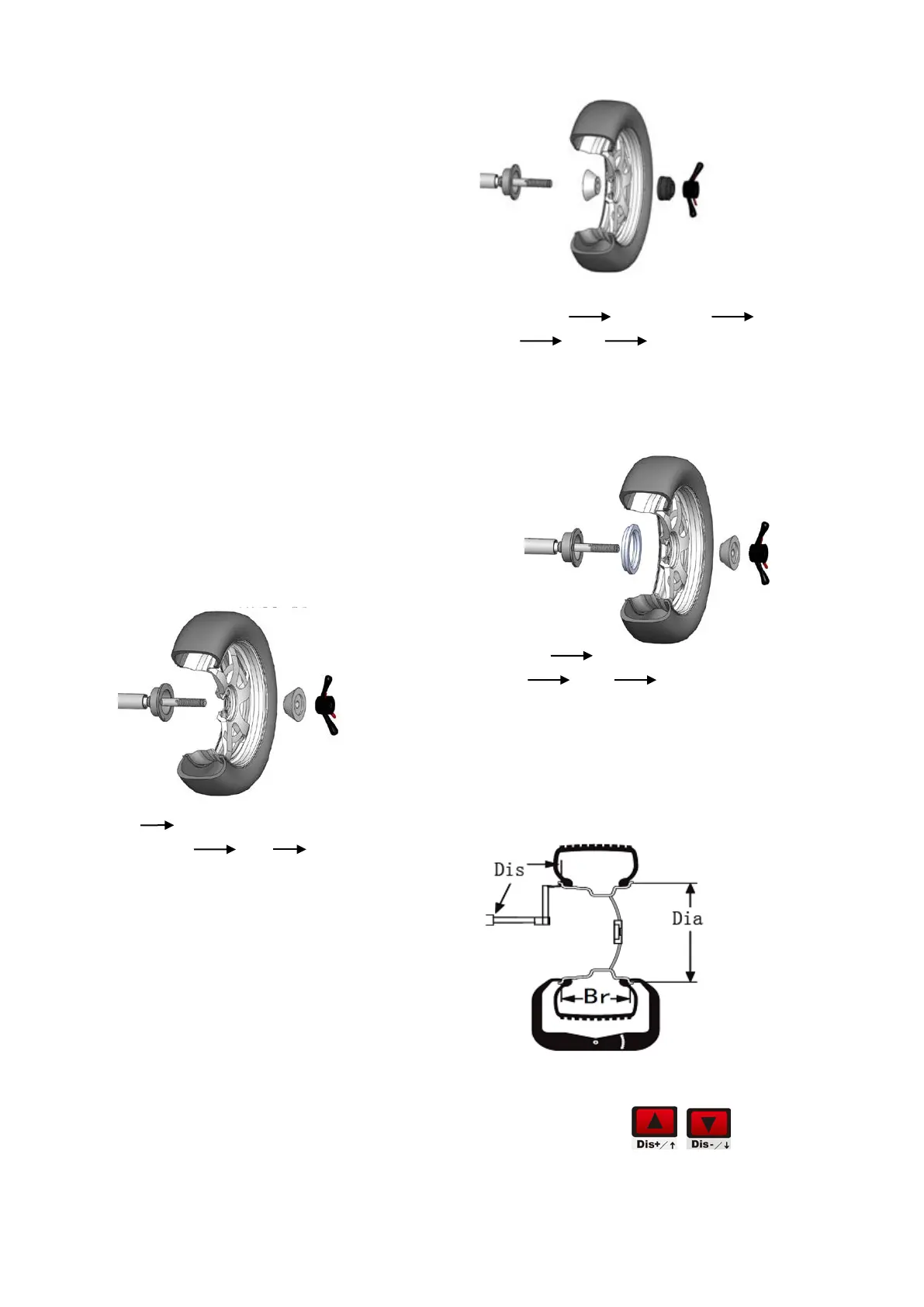

6.4 INPUT VALUE

6.4.1 Input DIS

(Distance)

Pull the scale to the inner position to add the weight

and press the key

to input the DI

value into the display. At this moment, the display will

Loading...

Loading...