3. MAINTENANCE

IOM manual Tapflo Metal Series 21

3.6. Aluminium and cast iron – Assembly of the pump

The assembly procedure is done in the reverse order to the disassembly.

Nevertheless there are a few things that you have to remember in order to assemble the

pump correctly.

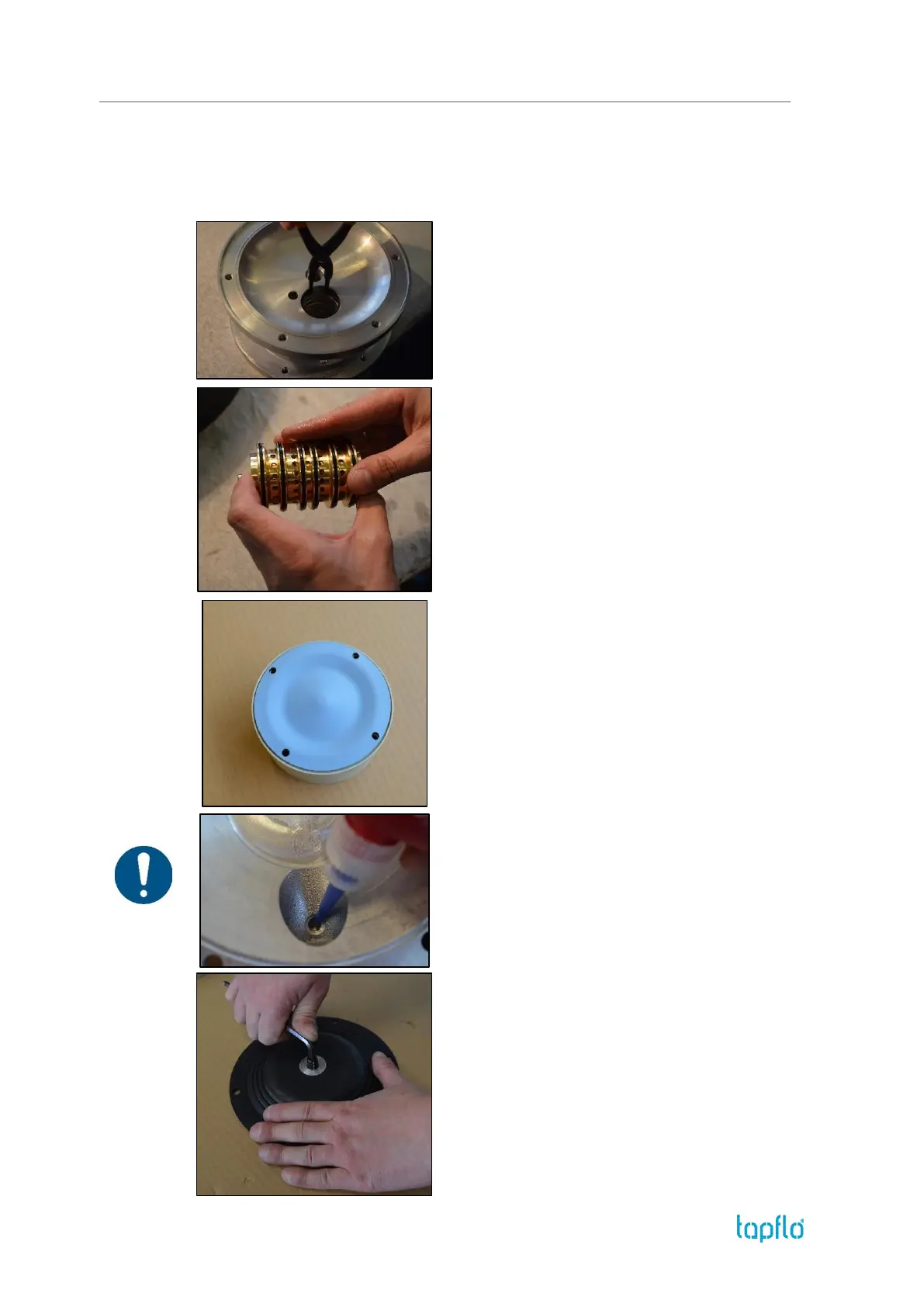

Fig. 3.6.1

Before inserting the air valve [61], insert the circlip

[27] on one side of the centre block [12].

Fig. 3.6.2

When putting the air valve [61] into the centre block

[12], apply some water or alcohol on the

O-rings to provide smooth insertion of the air valve.

It is recommended to use a pressing device for this

operation.

ATTENTION! When inserting the TX25 size air valve,

replace the shaft with a screw and a nut to make sure

the air valve assembly remains properly fastened.

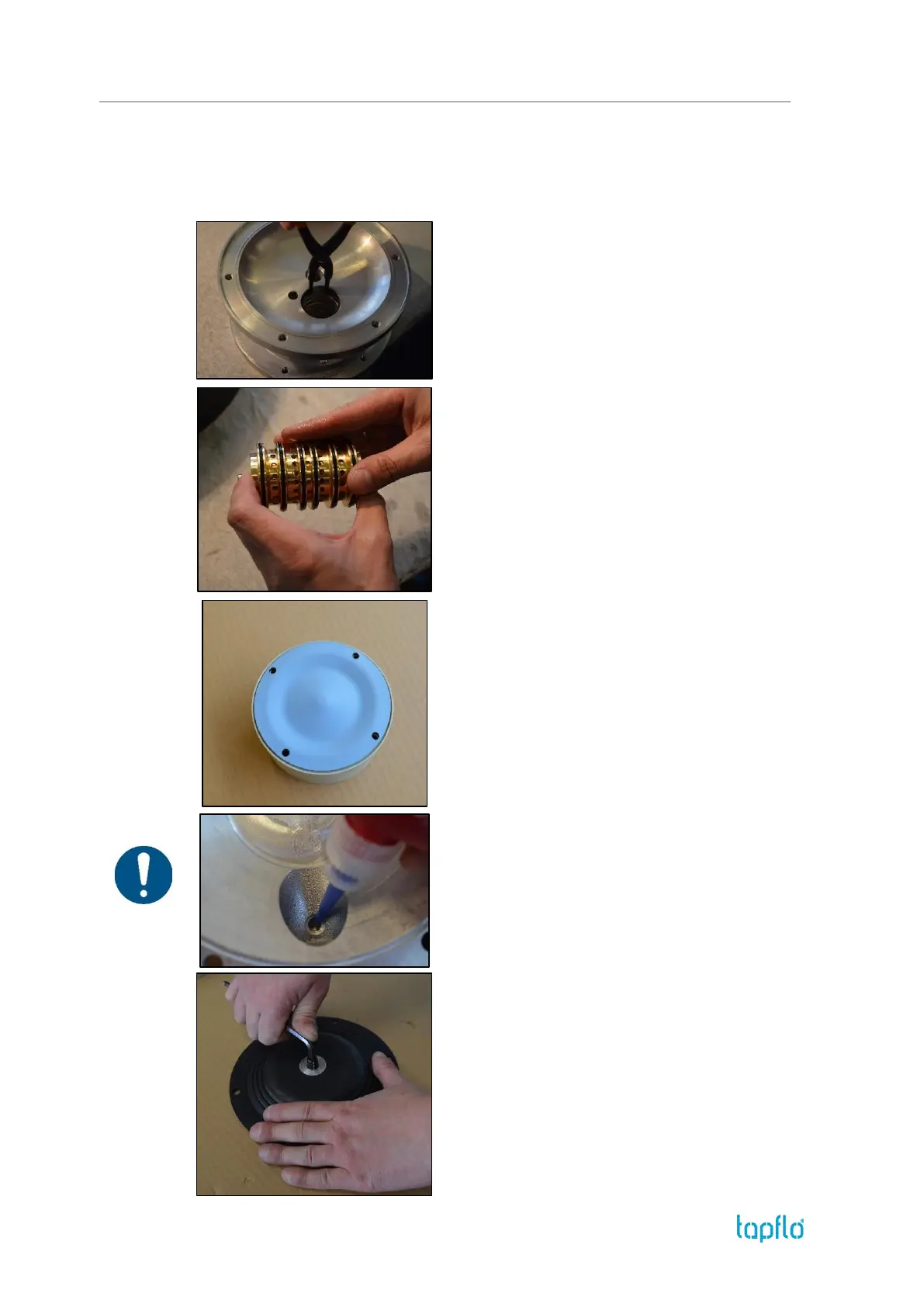

Fig. 3.6.3

When screwing in the diaphragms [15] on the shaft

[16], the holes in the diaphragms must align with the

holes in the centre block [12]. Sometimes it is

necessary to turn the diaphragm back a little bit in

order to align the holes.

Fig. 3.6.4

Apply some Loctite 243 on the thread before

screwing in of the valve ball stops [22].

ATTENTION! Make sure the glue is inserted on the

thread and not only on the bottom surface of the

orifice.

Fig. 3.6.5

When assembling the diaphragms [15], the first step

is to screw the grub screw into one of the diaphragms

as much as possible.

Loading...

Loading...