20

Troubleshooting

Models 340/341/342

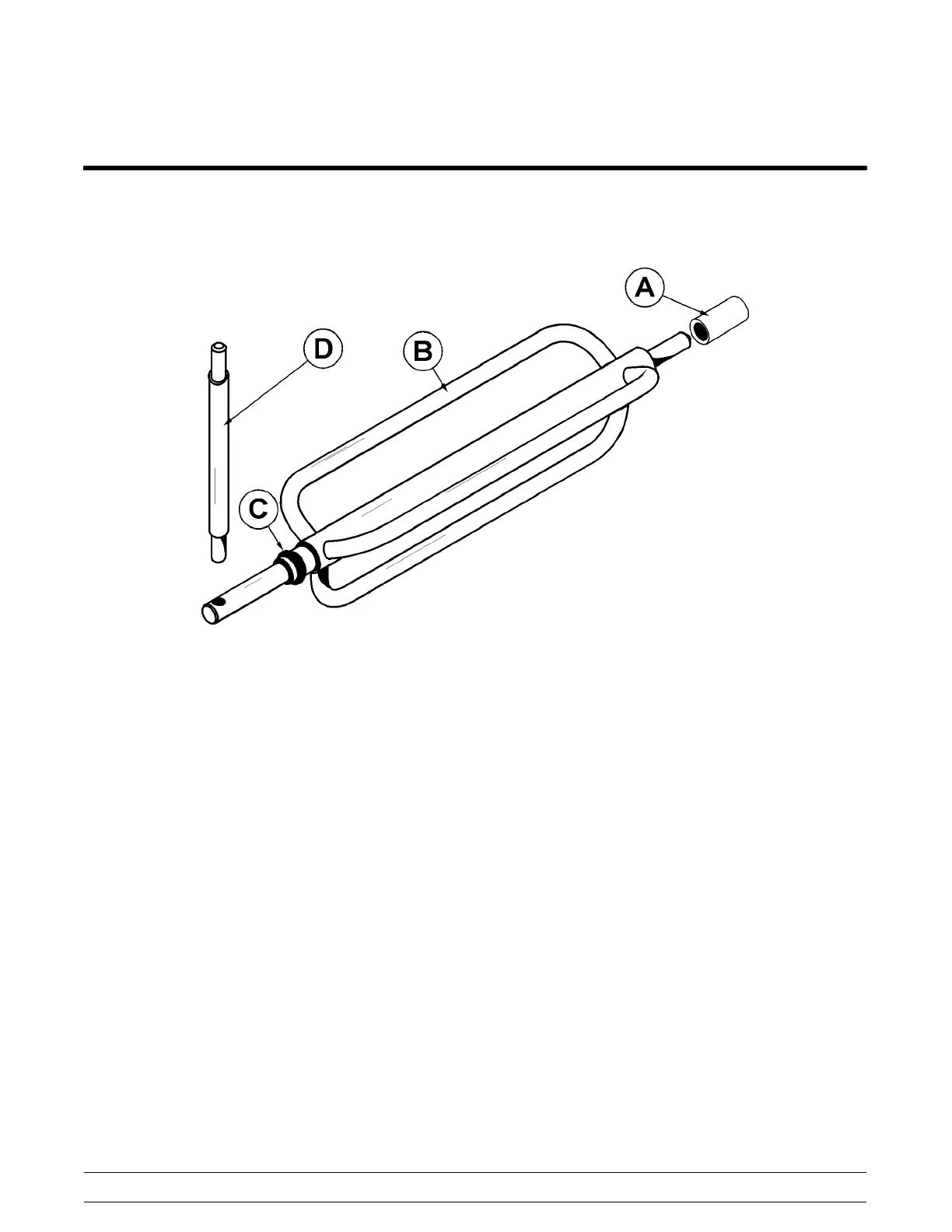

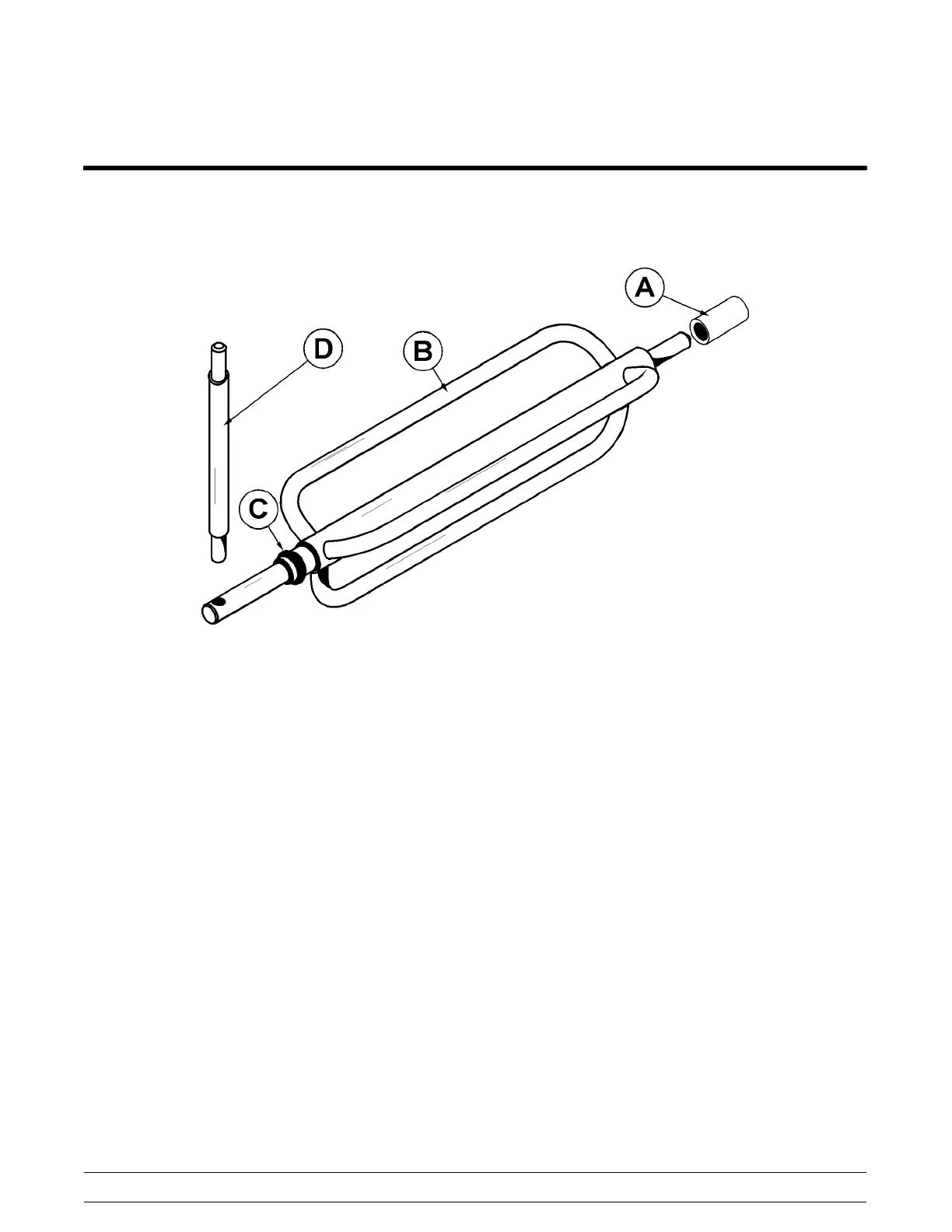

Troubleshooting Torque Components

A. A missing or worn guide bearing will cause

uneven movement of the rotor system, and will

result in product inconsistencies (too stiff/too

thin). If product becomes too stiff, the door,

torque arm, torque rotor and torque lever may be

damaged.

B. Any distortion or incorrect assembly of the torque

rotor will damage the torque components.

C. If incorrectly sized, damaged or improperly

lubricated o-rings are used, the rotor, door,

torque arm, torque rotor and torque lever may be

damaged.

D. If the torque arm is missing, the product will

freeze and the pulley belt will begin slipping. The

beater reset will then deactivate freezer

operation. In addition, torque components may

be damaged.

Loading...

Loading...