22

Section IV – Pipeline Under Pressure

1.0 THREAD-

O-RING Nipple

Installation

1.0 THREAD-O-RING NIPPLE INSTALLATION

1. 1 Tapping Requirements

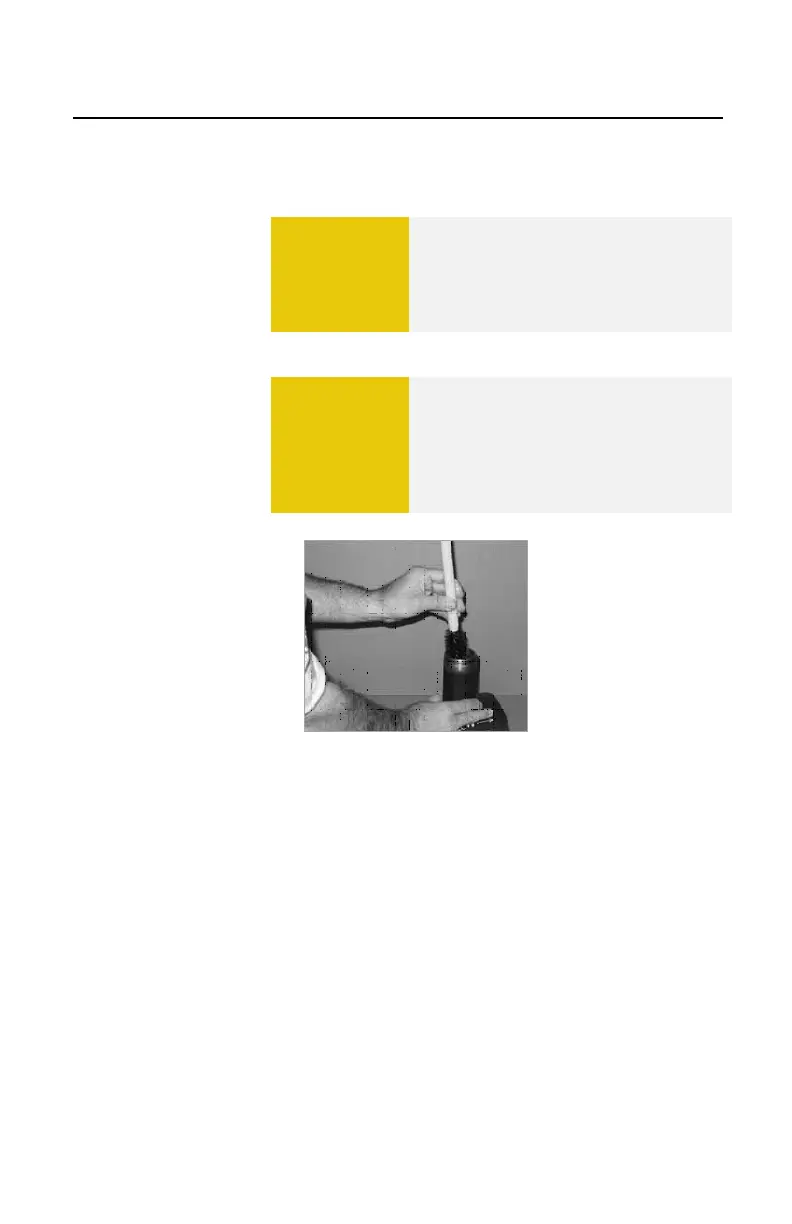

Figure 4.1.

Brush Threads

A. A THREAD-O-RING nipple can be welded to the

pipeline then tapped through, using a T-101

drilling machine and a 1-7/16-inch drill.

B. The nipple must be welded so that it is on the top

centerline of the pipe and perpendicular to it.

CAUTION

The PIG-SIG V plug assembly can

be damaged and may not operate

properly if the THREAD-O-RING

nipple is not installed correctly or if

the opening in the pipe is too small.

CAUTION

Clean the threads of the THREAD-O-

RING nipple before installing the

PIG-SIG V plug. The plug threads

may gall and/or be damaged if debris

is not removed prior to installation

Loading...

Loading...