63

Section VII – Maintenance

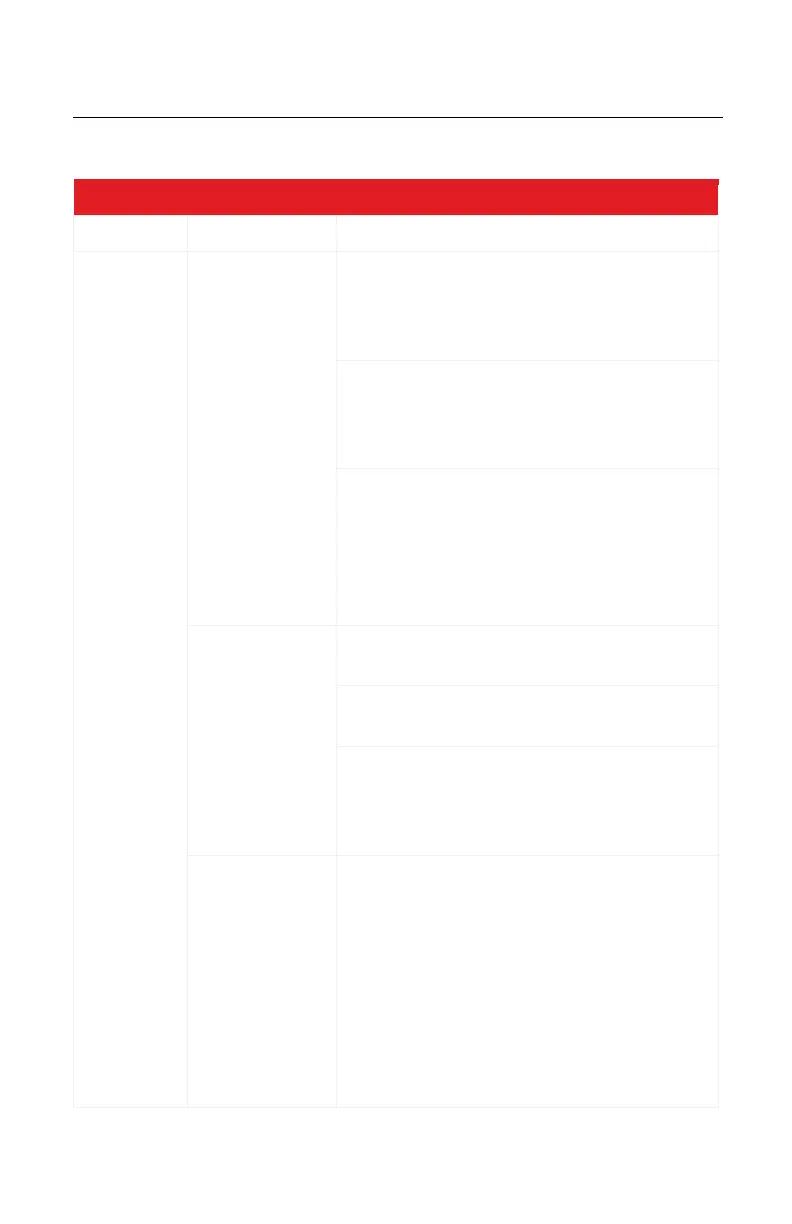

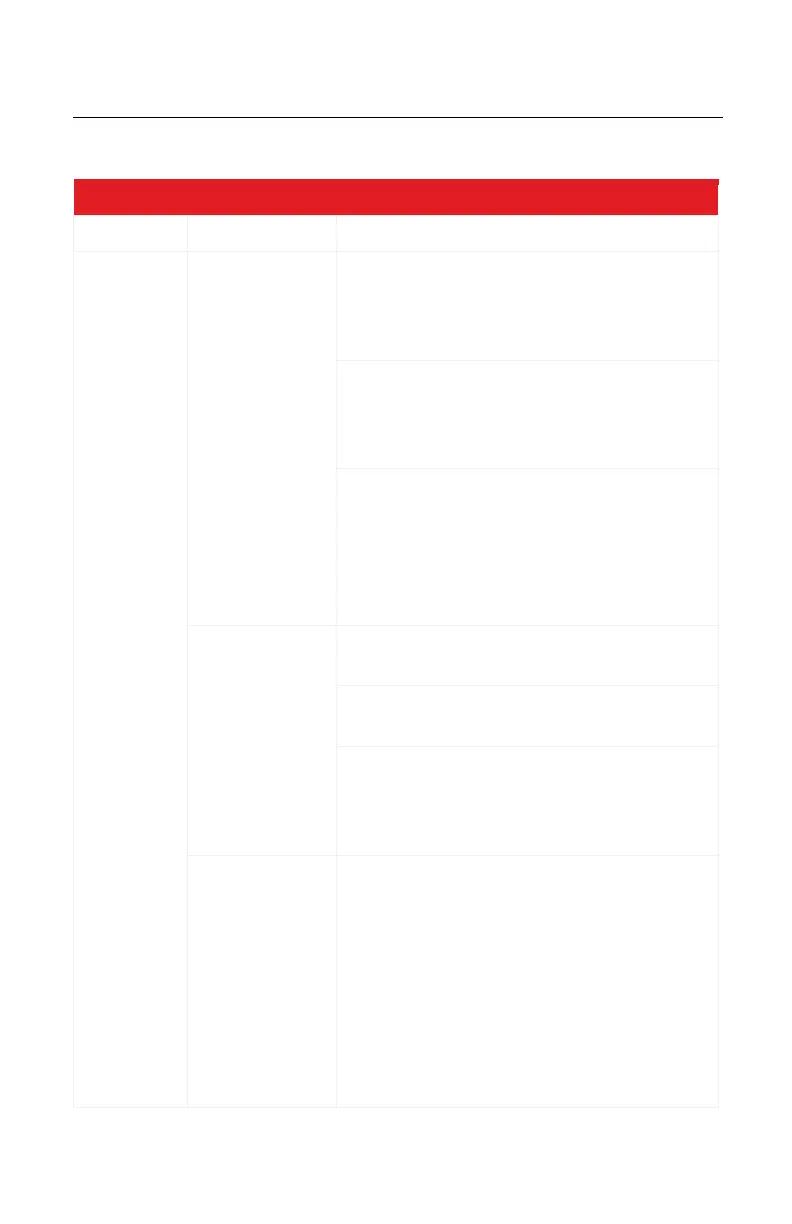

2.0 TROUBLESHOOTING

Table 10. PIG-SIG V Troubleshooting Guide

raise after

assumed pig

passage.

Verify indicator is properly installed:

check indicator installation by removing a

set screw and looking for the groove on

Verify that the plug is fully installed:

Measure the distance the plug extends

above the THREAD-O-RING nipple

(should be 1-3/8 inches).

In the event of freezing weather: the seal

on the indicator may have been

compromised allowing water to enter the

upper portion of the plug. This water can

freeze and not allow the magnet to move.

Remove indicator and check for moisture.

wo

to the

THREAD-O-

RING Nipple.

Verify that it is indeed a TDW THREAD-

O-RING.

The hole in the pipe may be too small or

not centered.

THREAD-O-RING may be swedged due

to over-tightening of a valve or cap.

Measure the inside dimension (ID) to

ensure it is not swedged or egged.

never worked

correctly.

Verify proper THREAD-O-RING was

used for corresponding wall thickness of

pipe. Measure the height of the THREAD-

O-RING as it is mounted to the pipe and

then add that measurement to the wall

thickness of the pipe. This measurement

should not exceed 4.50 inches but needs

to be greater than 4.25 inches.

Loading...

Loading...