42

Section IV – Pipeline Under Pressure

3.0 Plug

Recovery

3.0 PLUG RECOVERY

3.1 Preparations

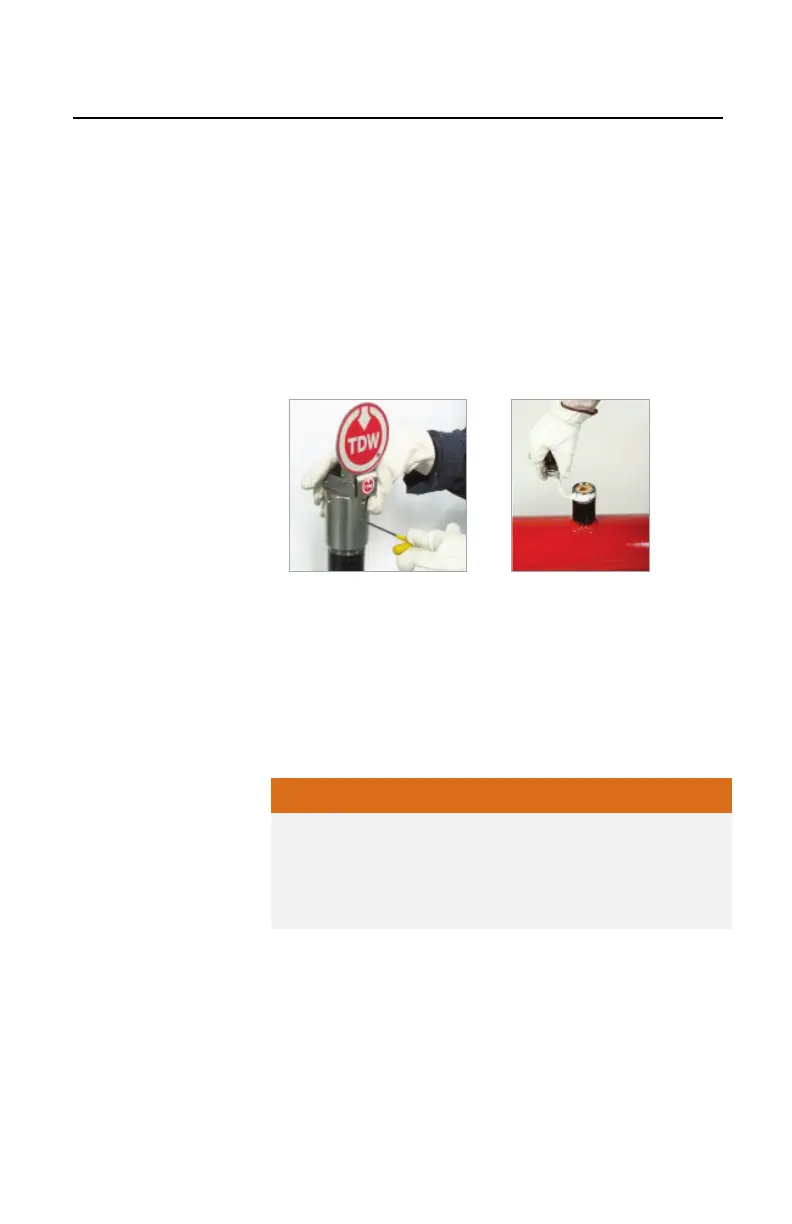

A. Remove the three set screws (Figure 4.40)

and

r

emove the flag indicator from the plug by pullin

g

s

traight up. Do not turn the cap during t

he

r

emoval process.

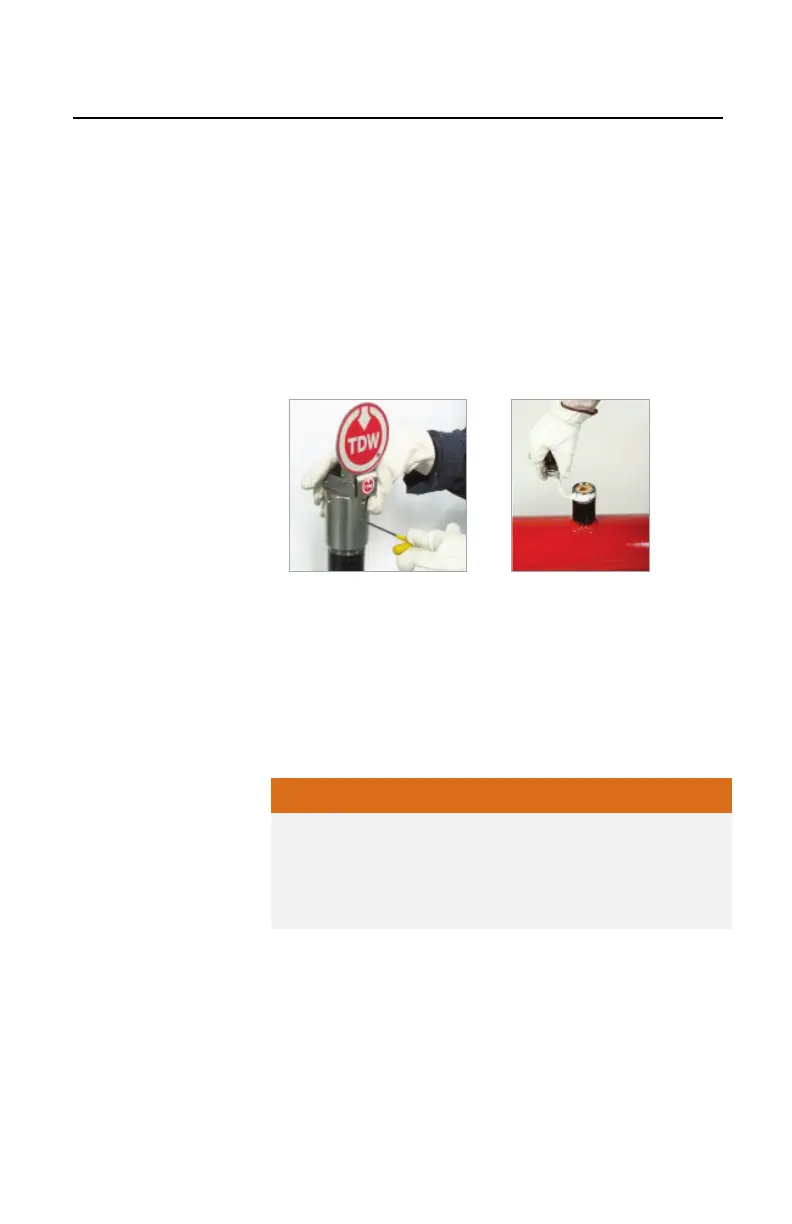

B. Clean the external threads and check for any

damage.

C. Threaded Valves: Apply thread paste (pi

pe

dope)

to the external threads (Figure 4.41).

Figure 4.40. Remove Set Screws.

Figure 4.41. Apply Thread

Paste

D. Select the appropriate tapping valve, whether

flanged or threaded, and install the tapping valve

onto the THREAD-O-RING fitting. Ensure the

valve has a minimum bore clearance of 2-1/16-

inches.

E. Lea

ve the valve in the open position.

Select a tapping valve which will allow the PIG-SIG to

pass through the bore. The bore should be

unobstructed by seat rings, lugs, etc. The bore of the

valve must be round and have a minimum inside

diameter of 2-1/16-inches.

Loading...

Loading...