Flushing technology

6-13

Protection class II

CE low voltage power

supply

Operating temperature - °C to + °C

Safety standard EN /EN

EMV standard EN /B

Technology Switching

Switch frequency KHz

Dielectric resistance V/ min

MTBF (MIL HDBK) , h

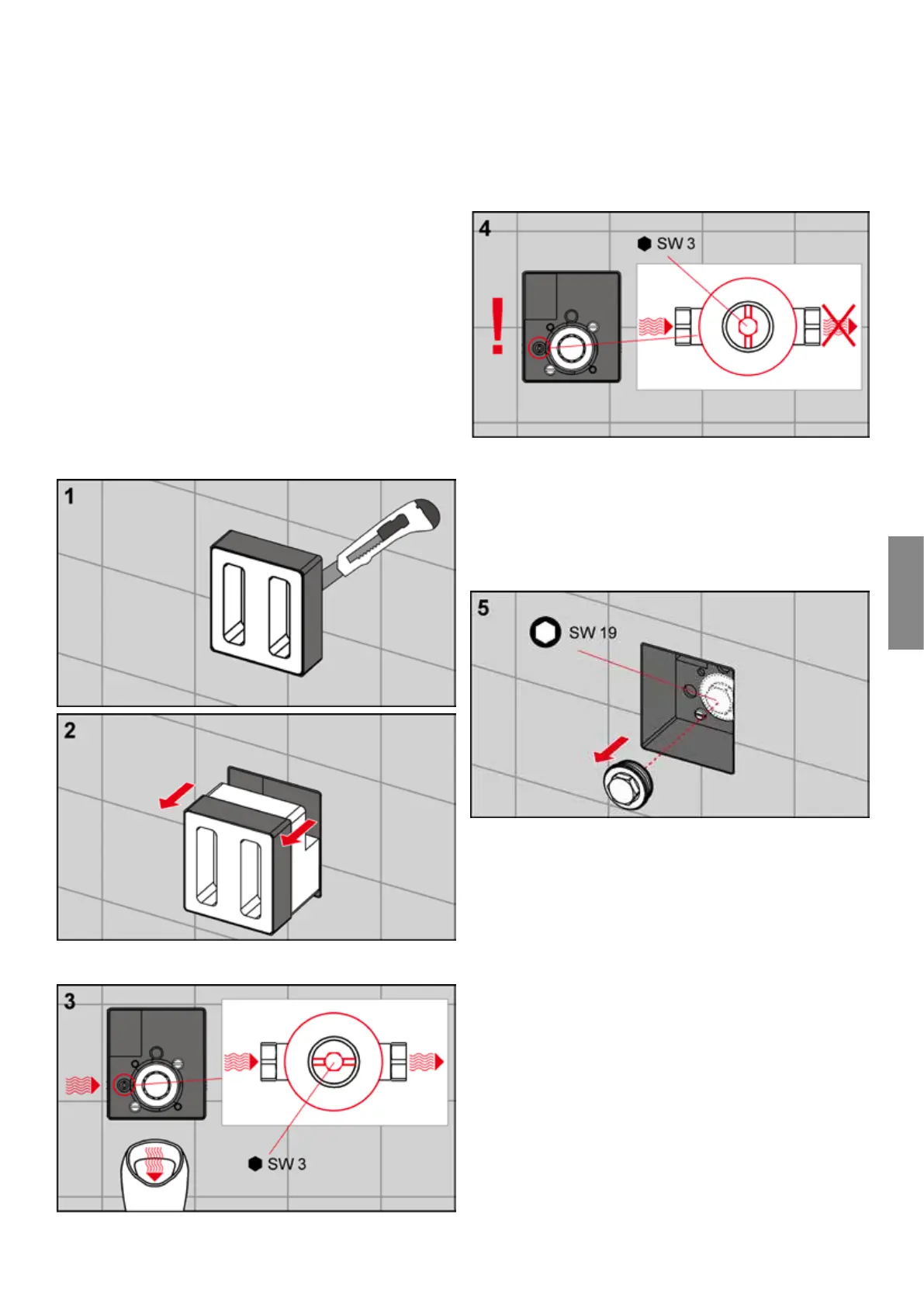

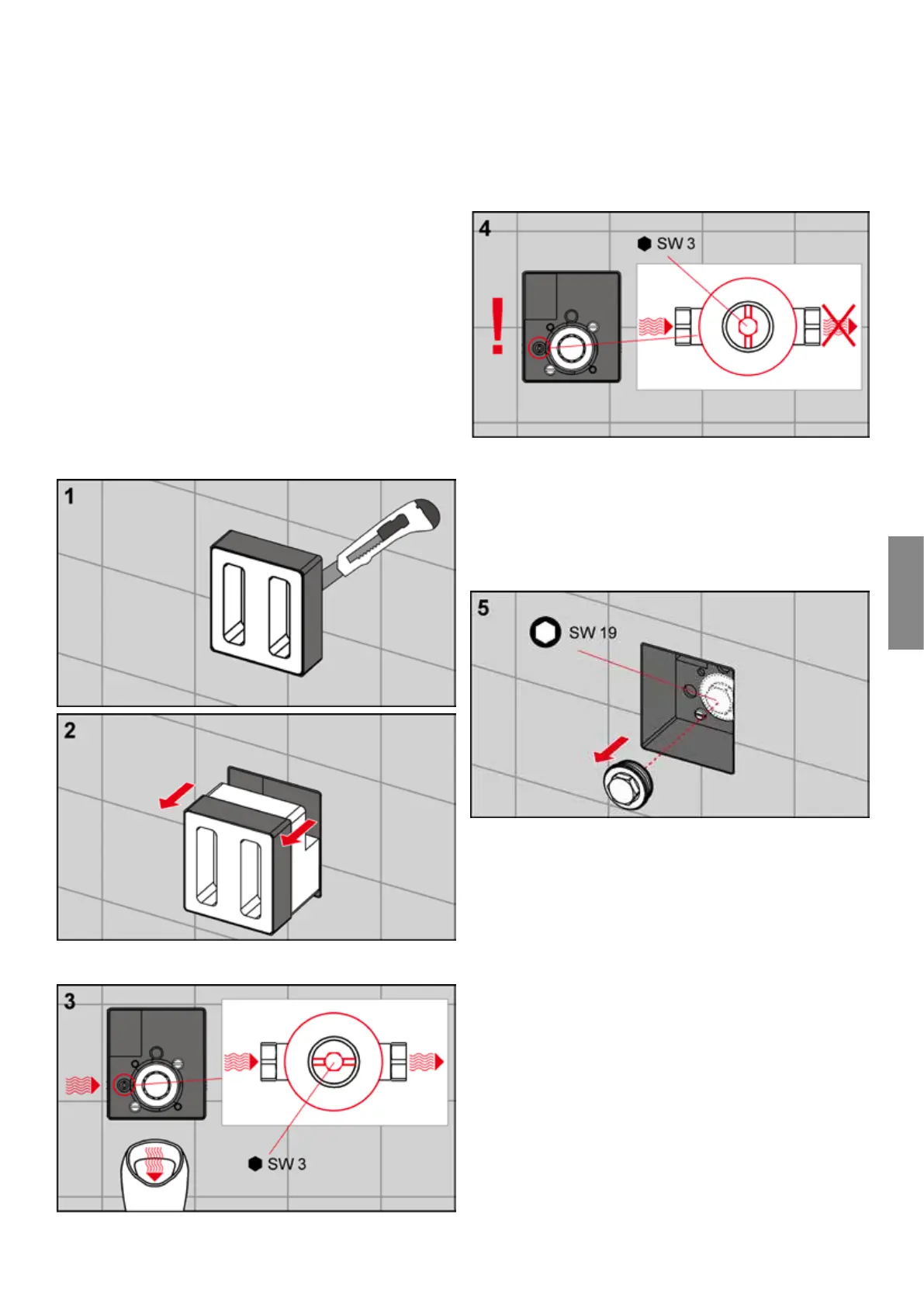

Installation of urinal flush valves

The installation procedures for the mechanical and the

electronic flush valves are practically identical:

Cut the bare-wall protection flush against the wall, and

remove it together with the polystyrene support.

Suciently flush out the pipe.

Observe the following:

When performing the pressure test, the inlet flow control of

the flush valve must be set to free-flow.

Before mounting the cartridge, ensure that the inlet flow

control is closed so that no water can leak out during

assembly. Close the shut-o using an Allen key. In the

free-flow setting (fig. ), the shut-o slot is parallel with

the housing, and in the closed setting (fig. ), it is at right

angles to the housing.

Remove the bare-wall plugs.

Loading...

Loading...