3

1 General features of the machine

1.1 Machines name:

- Bending machines type PG 26 ; PG 30 ; PG 35 ; PG 40.

- Combined machine type PGT 32/25.

1.2 Machine description:

The bending machines are electrically driven with manual control and they are built for the bending of

reinforced-concrete bars to produce shaped and stirrups.

The bending operation is executed coldly through the rotation of a bending disc with central pin and a

rotating pin allowing the bending operation thanks to the bars axial push.

The combined machines are electrically driven and are built for the bending and cutting of reinforced-

concrete bars to produce shaped and stirrups.

The cutting operation is executed coldly through two knives, one fix and one mobile, which is driven

by a rod, allowing the necessary movement for the cutting.

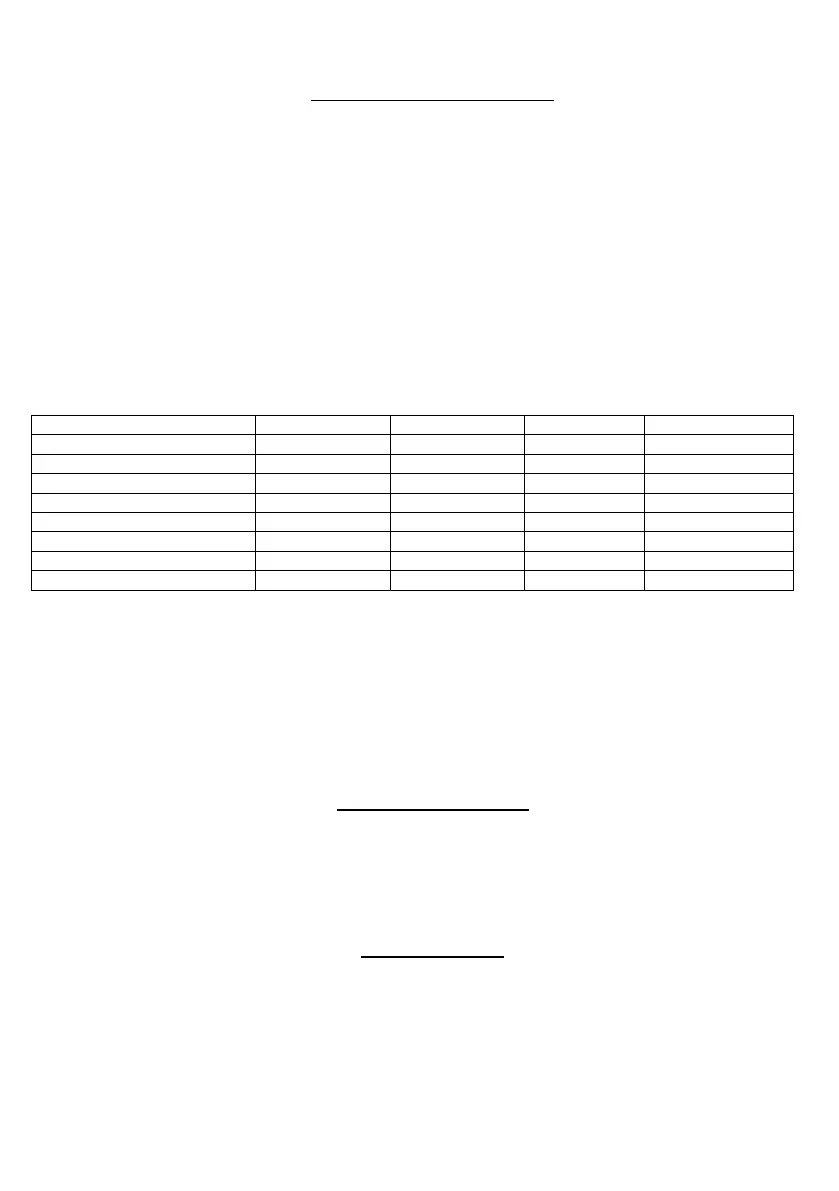

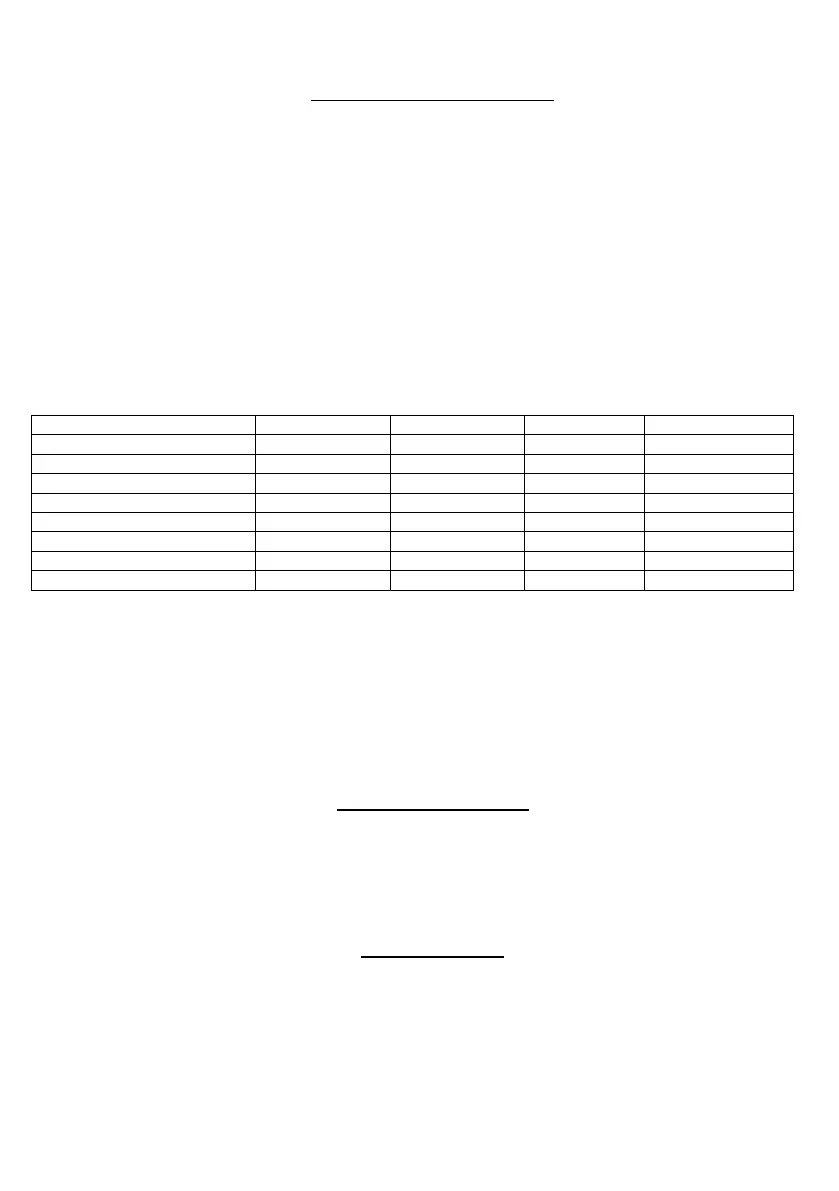

1.3 Technical data:

1.4 Marking:

The Certificate of Conformity on page 2 shows the following information:

• Name and address of the producer.

• CE mark.

• Type of machine.

• Serial number.

• Year of construction.

The same data are indicated on a plate fixed on the machine.

2 Transport and unpacking

The machine is delivered on a pallet and covered by a polyethylene sheet, all fixed by strapping so

packing and machine are a unique bloc.

For the unpacking, only eliminate the strapping and the polyethylene sheet (keep it to cover the

machine at the end of its working).

3 Lifting and moving

For a safe machine moving you can:

a) Lift it catching steel wires to two hooks already fixed on the machine body. The steel wire must have a

diameter big enough to lift the indicated weight, as in the technical feature schedule.

Each time the hooks are used, check that they are well fastened in way their base is on the

machine body.

b) Use a lift truck or a pallet truck in case the machine is on a pallet (strong enough for the machine

weight. During the machine handling and transport, it is forbidden to turn it over or on one side

different from the normal ground-side. It is also forbidden to tilt the machine for more than 30°, in

order to avoid oil exit.

Loading...

Loading...