6

8a.2 Starting and working:

All the following operations must be executed maintaining the working plate free from any equipment

and without inserting any pin into the disc.

• Connect the supply cable as above described.

• Turn the main switch-inverter from the starting position 0 into position 1 or 2 according to the required

rotation direction. Push the reset button: now the light is on. In this way the bending disc does not

move in case it is already in the correct starting position. On the other hand, it moves to get

the correct starting position.

• Start the machine pushing the pedal to check the disc rotation direction. Stop the machine elevating

the foot from the pedal. Push the return button to place the disc in the starting position.

• The machine is ready to use the toolings.

• The reset operation has to be executed each time that:

- The machine stops because of the emergency-stop button.

- Voltage is untimely restored.

- A starting operation is executed through the main inverter-switch.

• To start the machine after an emergency STOP, it is necessary to unblock the button turning its

mushroom part and then to push the reset button; in this way the disc gets into the starting position,

ready for the following operations.

8a.3 How to bend a piece:

After all the above-described operations, prepare the toolings as follows:

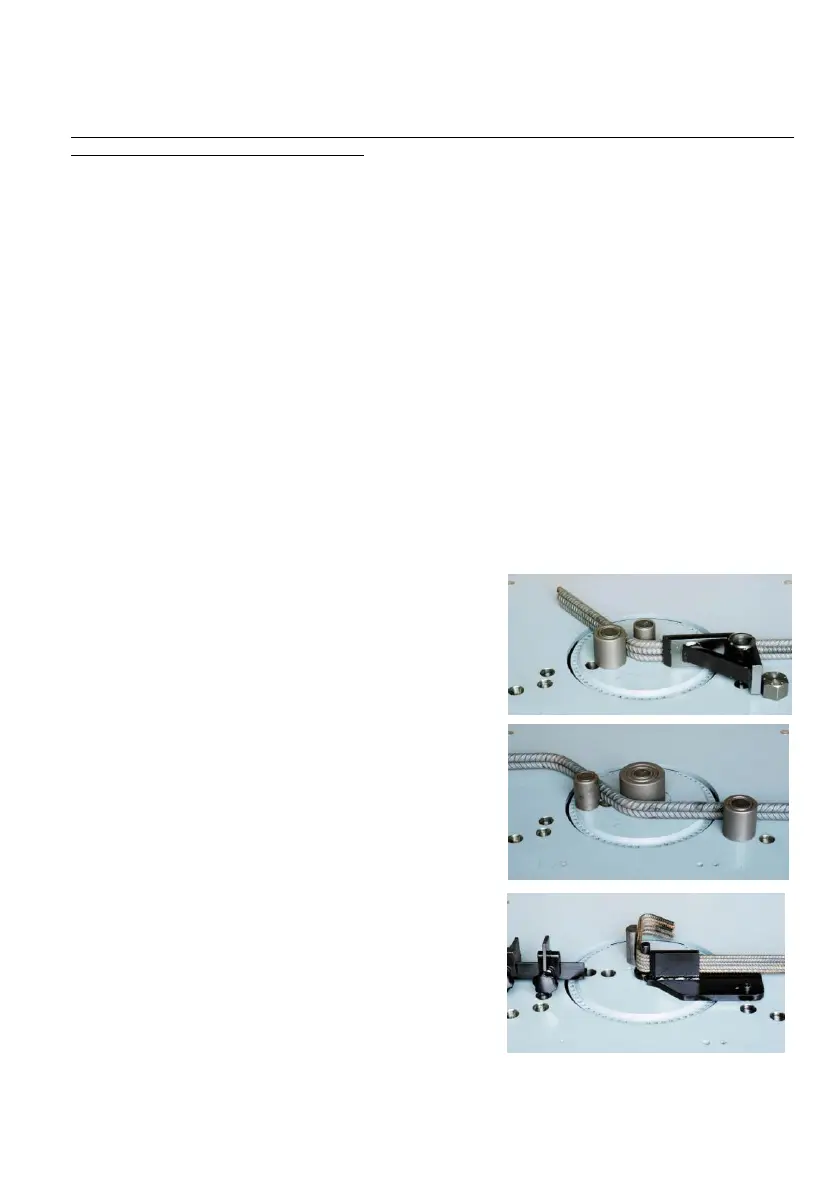

a) Bending operation with square:

The picture shows the correct position of the equipment

ready for the bars bending using the square only for iron

with maximum diameter 14 mm.

The bending square allows to place the bar near the

bending centre, obtaining a perfect bending angle.

Placing the equipment in this way, the disc must turn

clockwise. Placing the equipment on the left side of the

working plate and turning the disc anticlockwise, it is

possible to obtain the same bending angles with the iron

coming from the left side.

b) Bending operation with pin and bush:

The picture shows the correct position of the equipment

ready for the bars bending using the pin with bush instead

of the square, allowing the bending of big diameters,

forcing less the machine and obtaining less sharp

bending angles. Thanks to this system, it is possible to

use bushes with a bigger diameter, as required by the

present legislation.

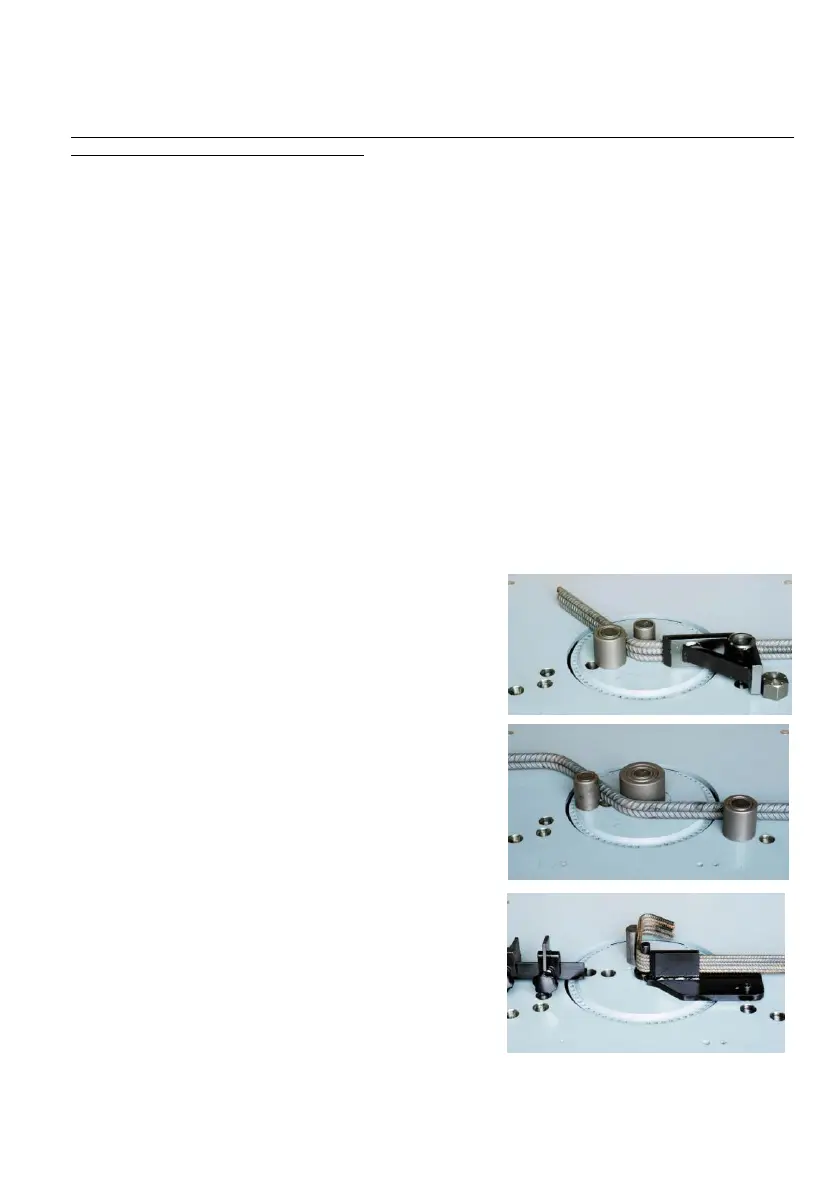

c) Stirrup bending with special tool:

(equipment on demand)

The picture shows the correct tooling for the stirrup

bending.

Three kinds of tools are at disposal:

- With central pin Ø20 for iron up to Ø10.

- With central pin Ø25 for iron up to Ø16.

- With central pin Ø30 for iron up to Ø20

Loading...

Loading...