The PID algorithm of the instrument is provided to program the following

parameters:

For

PROPORTIONAL term :

"Pb" - Proportional Band,

"rS" - Manual reset

"tcr1" - Output C1 Cycle time

For

INTEGRAL term:

"Int" - Integral time

For

DERIVATIVE term:

"dEr" - Derivative time

4.3 - DOUBLE ACTION PID CONTROL (C1,C2)

This kind of action can happen only when the instrument has both

regulation outputs (C1 and C2). In this case will not be visualised the

"Con1" parameter, because the only possible regulation mode is PID

double action. This kind of regulation is used to control installations where

there's an element which causes a positive increment (ex. heater) and an

element which causes a negative increment (ex. cooler). With "Func"

parameter will be decided C1 output functioning, while C2 output will

automatically works in the opposite way. For example, if "Func" ="HEAt"

to C1output will be connected the positive increment element (ex. heater)

while to C2 output will be connected the negative increment element (ex.

cooler). PID double action mode acts, therefore, on C1 and C2 outputs and

depending on Set point ("SEt") and on control algorithm programmed.

The PID algorithm of the instrument is provided to program the following

parameters:

For

PROPORTIONAL term :

"Pb" - Proportional Band,

"rS" - Manual reset

"tcr1" - Output C1 Cycle time

"tcr2" - Output C2 Cycle time

For

INTEGRAL term:

"Int" - Integral time

For

DERIVATIVE term:

"dEr" - Derivative time

Furthermore the parameter "Prat" (Power Ratio), on which it's necessary

to set the ratio between power of the element controlled by C2 output and

power of the element controlled by C1 output. If ever the parameter "Prat"

is = 0, C2 output is deactivated and the regulator behave exactly as a PID

single action, trough C1 output.

4.4 - AUTOTUNING FUNCTION

The instrument is set on parameters relative to PID control of standard

value. If ever these should result to be unsuitable it would be advisable to

program the AUTOTUNING function. The Autotuning function permits the

automatic tuning of the PID instrument parameters, whether single or

double action.

To active the AUTOTUNING function proceed as follows :

1) Set the desired "Set point".

2) Set, if present, "Con1" parameter = "Pid".

3) Set "Func" parameter depending on the process to be controlled, trough

C1output.

4) Connect the instrument with the plant

5) Set the parameter "Auto" as :

- "Sp" if it's desired to have autotuning on Set Point value programmed, or

:

- "LoSp" if it's desired to have autotuning on a lower value (equal to 70%

of Set Point programmed)

6) Go out of parameters programming

Now, the Autotuning function is activated and it's shown by the flashing of

the two external decimal point on the lower display (SV). The regulator

automatically tunes all the right parameters for a correct PID control

mode. Before to switch off the instrument always wait for the end of the

Autotuning process, indicated by the return of the display on the normal

functioning. During the autotuning execution are activated some ON-OFF

regulation cycles, that consequently make temperature swing abundantly

around set point value (a bigger or smaller temperature swing depends on

the process nature to be controlled and not on the instrument). If the

process doesn't allow to big temperature variations upper than set point

value, it's advisable to select autotuning cycle as "LoSP". The Autotuning

procedure has been limited at a maximum time of 4 hours, after this time, if

the Autotuning is not completed the instrument automatically get out from

the procedure, showing constantly on the display "tout Auto". In case,

instead, should happen an anomaly during autotuning, the instrument will

visualise "no Auto" flashing. To stop the Autotuning cycle or re-establish

the normal functioning after an error, switch off and on the instrument.

The calculated values will be automatically memorised by the instrument

at the end of the Autotuning cycle, in the PID control parameters.

4.5 - ALARM OUTPUTS OPERATING MODE (A1,A2)

To configure the alarms functioning, whom activation is depending on the

process value (A1,A2), it's necessary to set "rL1" ("rL2") with a code made

by 4 figures as following composed : a b c d where :

a :

Alarm type

b : Alarm latch

c : Start-up behaviour

d : Output logic mode

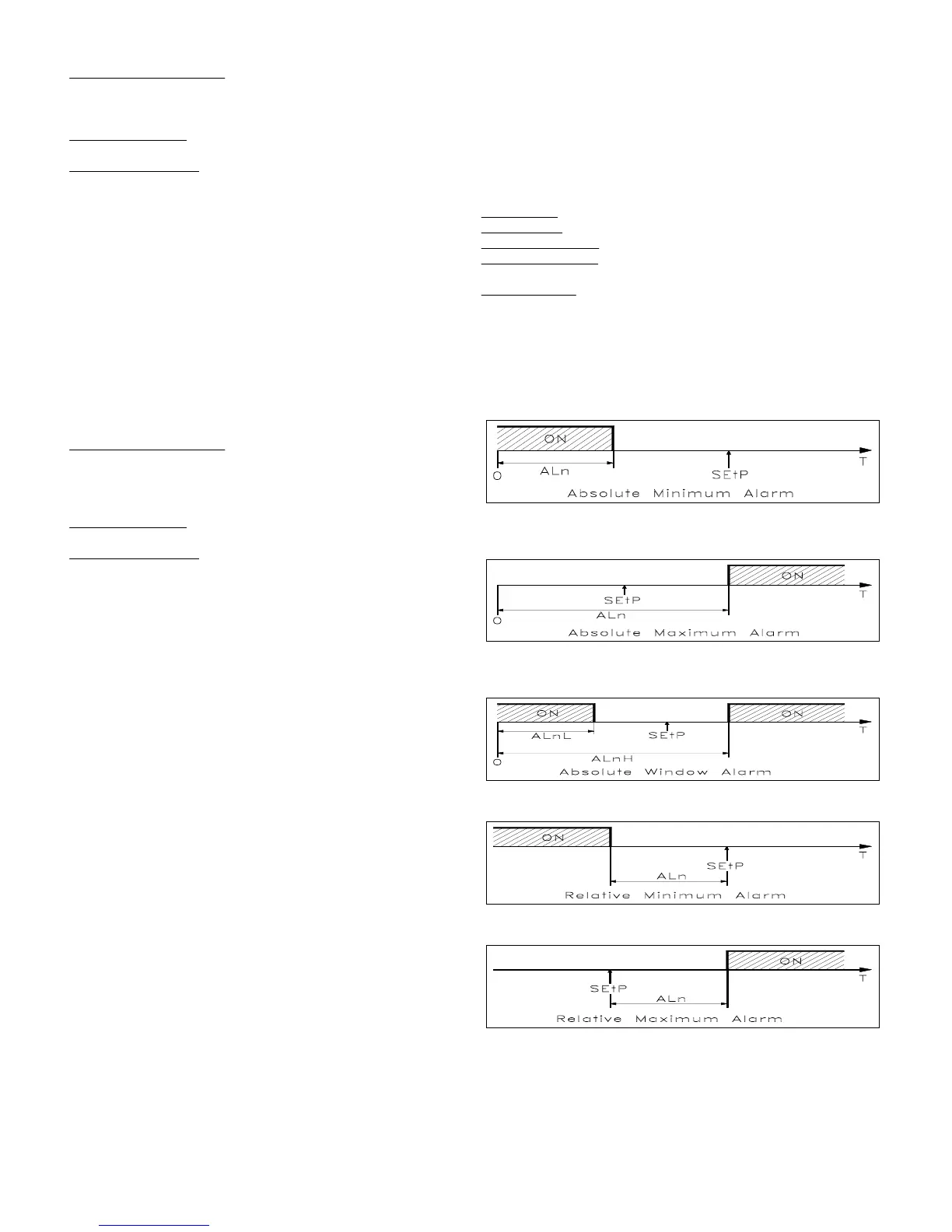

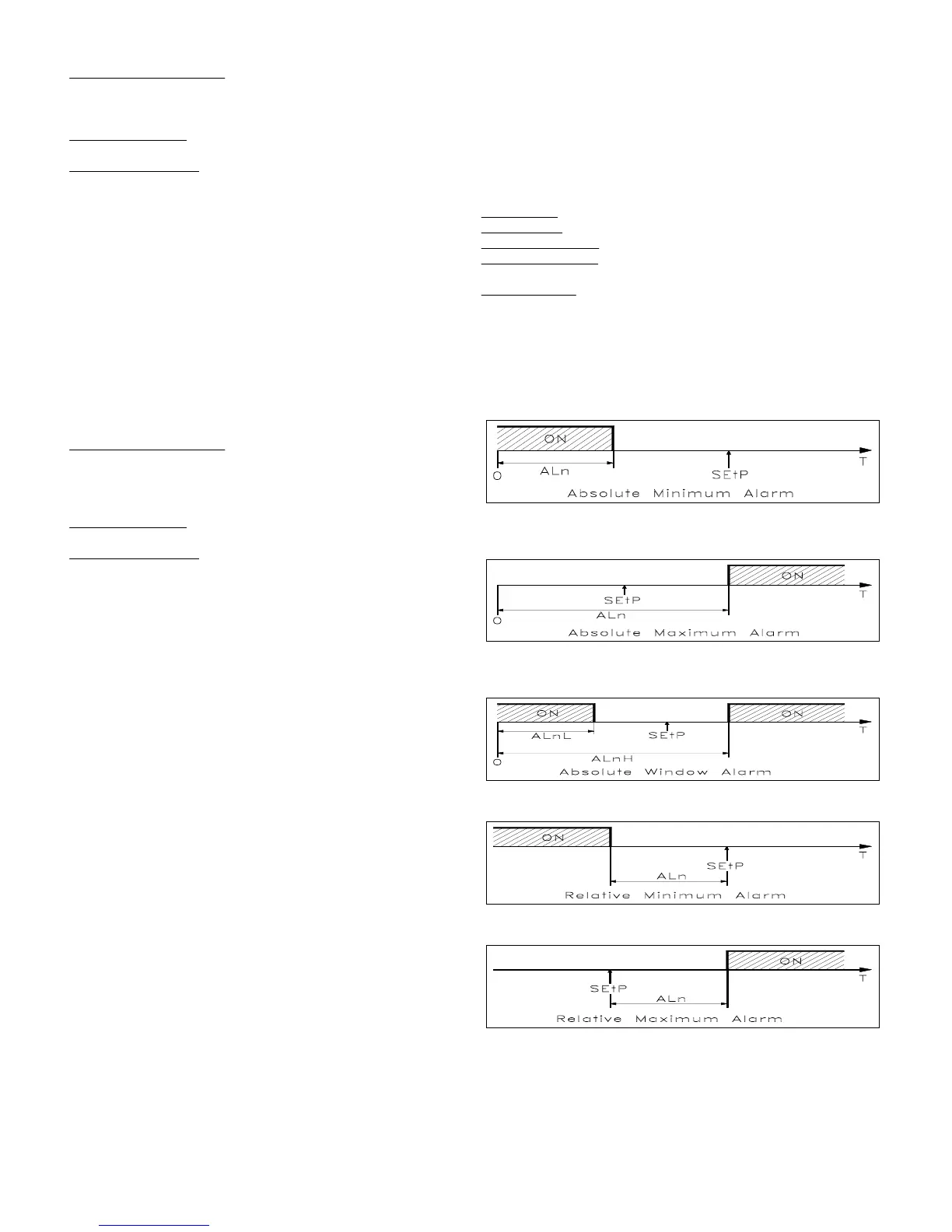

a - ALARM TYPE

It's possible to have 6 different alarm output behaviours, depending on the

value of the first code figure.

Note : Here following we'll indicate, in the examples, "ALn" to intend a

generic alarm (AL1 or AL2). Furthermore, when it's programmed the

window alarm type , instead of "ALn" will appear two parameters "ALnL"

(Lower set) and "ALnH" (Higher set).

0 = ABSOLUTE MINIMUM ALARM: The alarm is activated when the

process value goes under the alarm set programmed on "ALn" parameter.

1 = ABSOLUTE MAXIMUM ALARM: The alarm is activated when the

process value goes upper than the alarm set programmed on "ALn"

parameter.

2 = ABSOLUTE WINDOW ALARM: The alarm is activated when the

process value goes under the alarm set programmed on "ALnL" parameter

or goes upper than the alarm set programmed on "ALnH" parameter.

3 = RELATIVE MINIMUM ALARM: The alarm is activated when the

process value goes under the value [SEtP - ALn ].

4 = RELATIVE MAXIMUM ALARM: The alarm is activated when the

process value goes upper than the value [SEtP + ALn ].

5 = RELATIVE WINDOW ALARM: The alarm is activated when the

process value goes under the value [SEtP - ALnL ] or goes upper than the

value [SEtP + ALnH ].

TECNOLOGIC - THP 98 USER MANUAL (I - GB) - Vr. 01 - ISTR 00372 - PAG. 9

Loading...

Loading...