CALIBRATION PROCEDURE USING KNOWN LOAD CELL MV/V SENSITIVITY

SINGLE ACTIVE LOAD CELL PLUS HINGE PIVOT

It is assumed that the load cell system is connected to the EZE30 and the power is

on. The maximum and minimum display values, display increment size and decimal

point position should be defined prior to carrying out the calibration (See Menu 3).

For this example the display maximum is define as 2009, the display minimum is -

200, the display step size is 1 and there is no decimal point.

a)

b) Go to Menu 2.1 and set the display to

read the capacity of the load cell system or the weight value at which the

sensitivity is known. For this example the load cell capacity is 2000Kg @ 2mV/V.

But the hinge pivot on the opposite side of the tank carries half the load (if the

centre of gravity is in the middle of the tank). Therefore when there is 4000Kg in

Remember that all parameters under sections 1.1 - 1.3, 2.1 - 2.3 and 3.1 - 3.3 can

only be accessed or changed after the Recessed Enable Switch has been pressed.

Go to Menu 1.2. Press the 0 [Enter] key. The display will read the input signal in

mV/V. Make sure that the weighing system is empty or at the point where you

want the display to read zero. Press the 0 [Enter] key. This defines the actual

zero calibration point.

using the UP/DOWN and RIGHT keys

Example:

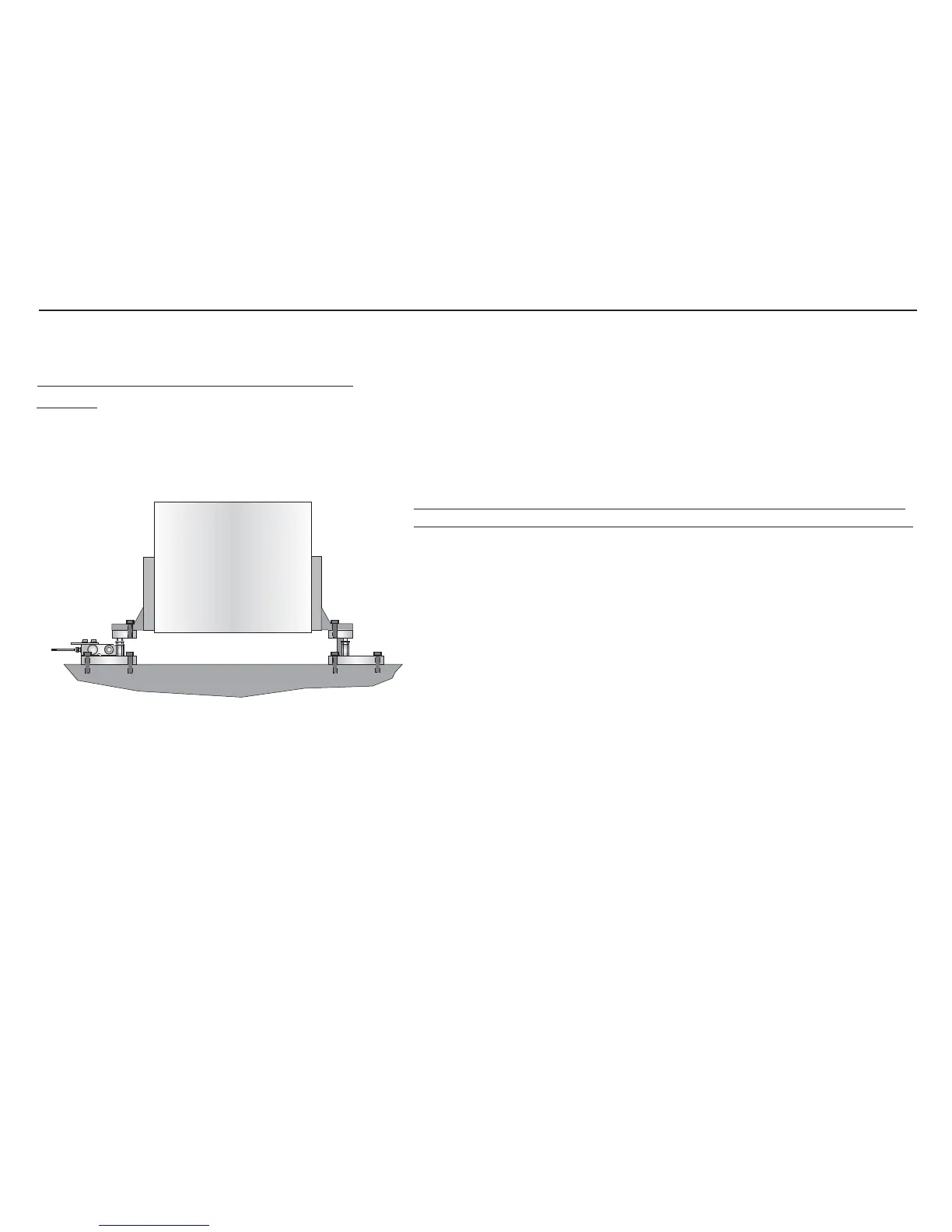

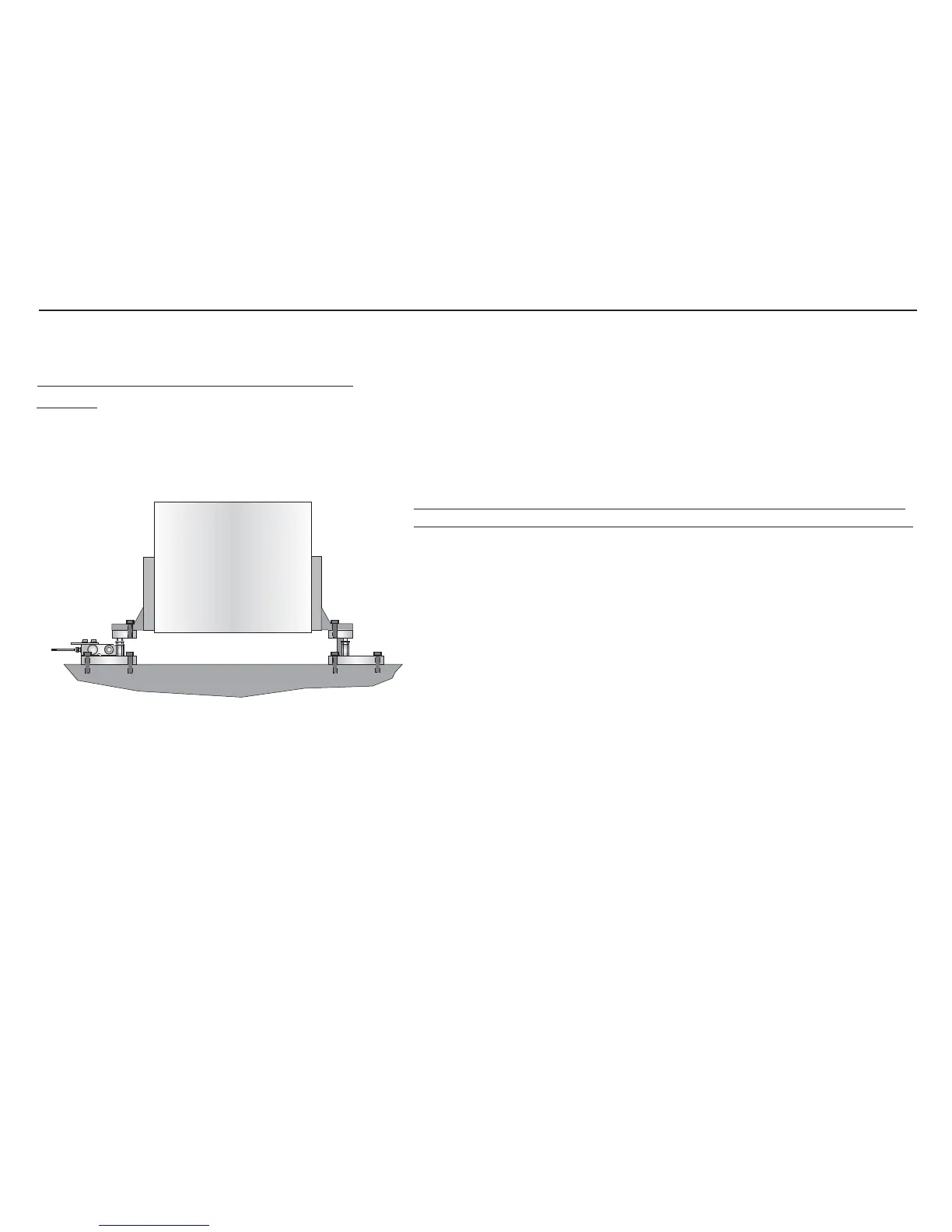

A rectangular tank fitted with 1 off 2000Kg 2mV/V load cell

central on the left hand side and a pivot (hinge) along the

complete opposite face .

Dead load 500Kg, Live range 2000Kg in 1 Kg steps

the tank equally split between the load cell and the hinge the output from the load cell will be 2 mV/V. The system is therefore 4000Kg

@2mV/V. Set the display to read 4000. This defines the theoretical calibration weight (equivalent to 2mV/V in this

example).

c) Go to Menu 2.3 and set the display to read the mV/V sensitivity of the load cell system you are using.

For this example the load cell sensitivity or Output at Rated Load is 2.000mV/V. In multiple load cell installations ( load cells wired in parallel)

the sensitivity is the average of all the load cells connected. This defines the theoretical span calibration point.

d)

PLEASE NOTE THAT IF THE LOAD IS NOT EQUALLY SHARED BY THE LOAD CELL AND PIVOT THE CALIBRATION WILL BE INACCURATE.

Press the 0 [Enter] key.

using the UP/DOWN and RIGHT keys

Press the 0 [Enter] key.

If required the zero can be re-calibrated without affecting the span. To do this make sure that the weighing system is empty or at the point

where you want the display to read zero. Goto Menu 1.2. Press the 0 [Enter] key. The display shows the actual input signal in mV/V. Press the

0 [Enter] key. Press the right arrow key twice and the DAS will be back in weighting mode.

Page 25

Loading...

Loading...