17

potential relay removes the start ca-

pacitor from the circuit after the mo-

tor is up to speed. This motor may

use either:

•anexternalthermalprotector,or

•aninternalthermalprotector.

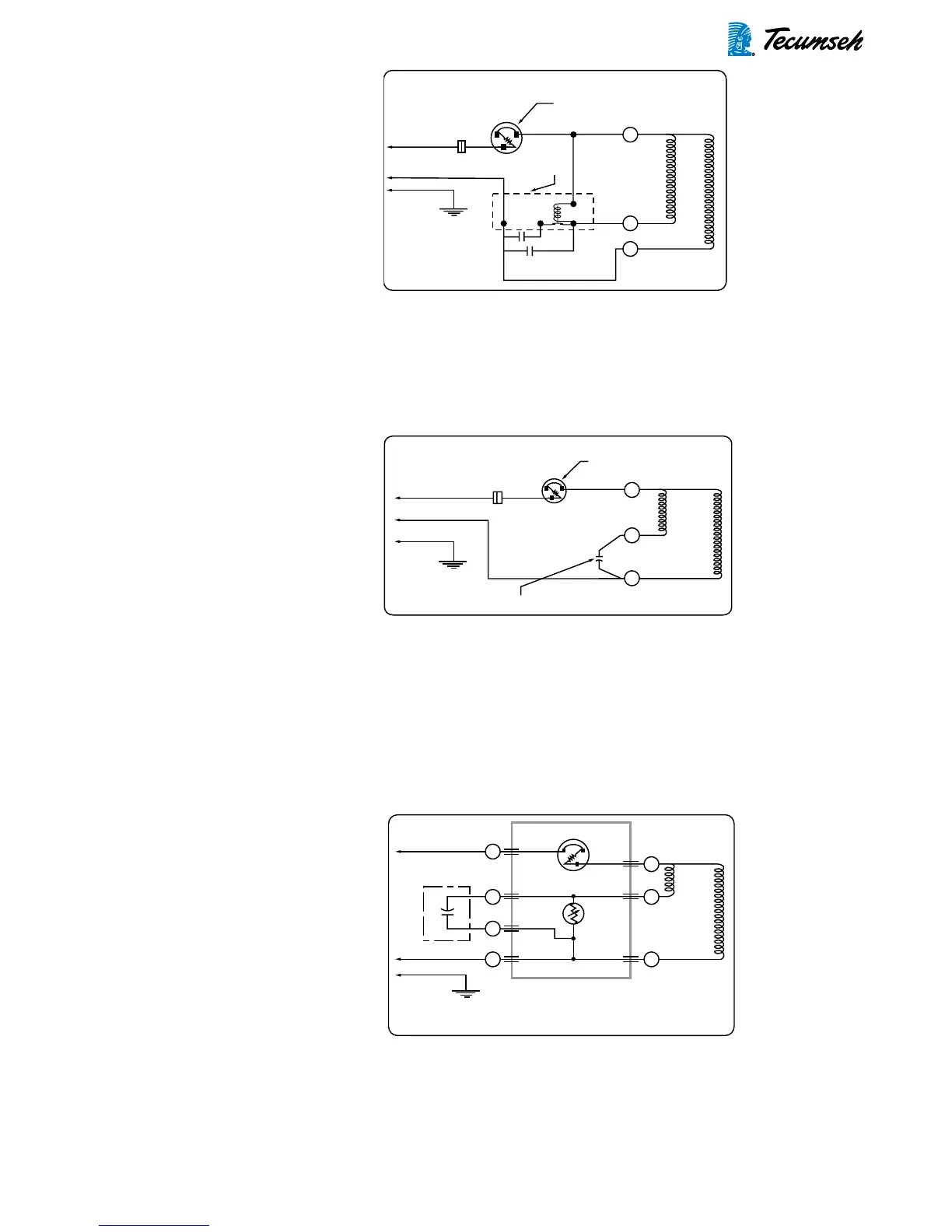

Permanent Split Capacitor

(PSC)

Here a run capacitor is in series with

the start winding. Both run capacitor

and start winding remain in the circuit

during start and after motor is up to

speed (see Figure 3-5). This normal

starting torque motor is sufficient for

capillary and other self-equalizing

system. No start capacitor or relay

is necessary. For additional starting

torque, a proper start assist kit may

be added (see Figure 3-6). Some

start assist kits may include:

•awired-inPositiveTemperature

Coefficient (PTC) relay, or

•amodulePositiveTemperature

Coefficient (PTC) relay.

This motor may use either:

•anexternalthermalprotector,or

•aninternalthermalprotector.

PSC motors are basically air condi-

tioning compressor motors and are

very common up through 5 HP.

PSC Motor Starting

Tecumseh Products Company pioneered the

development of Permanent Split Capacitor

compressor motors. This type of motor elim-

inates the need for potentially troublesome

and costly extra electrical components, e.g.,

start capacitors and potential motor starting

relays (see Figure 3-5).

To fully realize the capabilities of this simplified

type of compressor motor, it is necessary

to understand its starting and operating

characteristics and the field conditions that

can affect it.

The following conditions affect PSC motor

starting:

• Lowvoltage: Reduces motor start-

ing and running torque. A 10%

voltage drop reduces a motor’s

starting ability by 19%. Low volt-

age can cause no start, hard start,

light flicker, and TV screen flip flop.

PSC motor diagram with start

assist kit that includes a module

PTC relay

FIGURE 3-6:

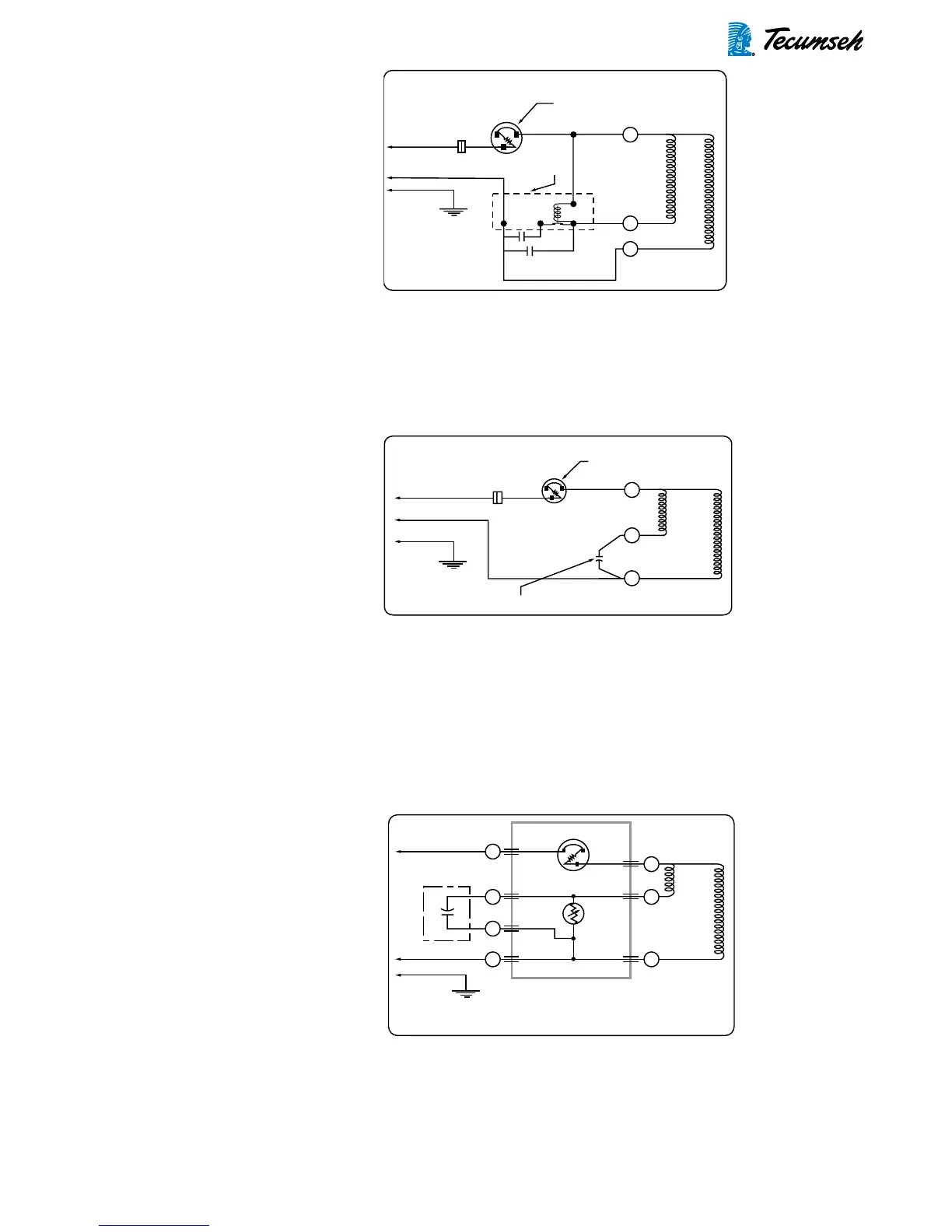

CSR motor diagram

FIGURE 3-4:

PSC motor diagram

FIGURE 3-5:

Relay -

Potential

Compressor -

Unit Ground

Line 1

Line 2

Ground

Start Winding

Main Winding

Control

External or Internal

Thermal Protector

C

S

R

Compressor -

Unit Ground

External or Internal

Thermal Protector

Run Capacitor

Line 1

Line 2

Ground

Start Winding

Main Winding

Control

C

S

R

Line 1

Line 2

Ground

Compressor -

Unit Ground

PTC

Relay

Plug-In

Run Capacitor

PTC Starting and

Protector Package

Thermal Protector

Start Winding

Main Winding

C

C

C

2

C

1

N

S

R

(115

Volt Only - Neutral)

(115

Volt Only - Neutral)

Relay -

Potential

Compressor -

Unit Ground

Line 1

Line 2

Ground

Start Winding

Main Winding

Control

External or Internal

Thermal Protector

C

S

R

Compressor -

Unit Ground

External or Internal

Thermal Protector

Run Capacitor

Line 1

Line 2

Ground

Start Winding

Main Winding

Control

C

S

R

Line 1

Line 2

Ground

Compressor -

Unit Ground

PTC

Relay

Plug-In

Run Capacitor

PTC Starting and

Protector Package

Thermal Protector

Start Winding

Main Winding

C

C

C

2

C

1

N

S

R

(115

Volt Only - Neutral)

(115

Volt Only - Neutral)

Relay -

Potential

Compressor -

Unit Ground

Line 1

Line 2

Ground

Start Winding

Main Winding

Control

External or Internal

Thermal Protector

C

S

R

Compressor -

Unit Ground

External or Internal

Thermal Protector

Run Capacitor

Line 1

Line 2

Ground

Start Winding

Main Winding

Control

C

S

R

Line 1

Line 2

Ground

Compressor -

Unit Ground

PTC

Relay

Plug-In

Run Capacitor

PTC Starting and

Protector Package

Thermal Protector

Start Winding

Main Winding

C

C

C

2

C

1

N

S

R

(115

Volt Only - Neutral)

(115

Volt Only - Neutral)

Loading...

Loading...