83

7. If a suction line accumulator is present, charge into the accumulator to prevent liquid

refrigerant from reaching the compressor. If this is not possible, then break the vacuum

by allowing refrigerant vapor to enter the low side at the suction service valve. When

the system pressure reaches 60 psig for R-22 (70 psig for R-502 & R-404A, 35 psig for

R-12 & R-134a), start the compressor and continue charging at rate not more than 5

pounds per minutes for the larger systems and somewhat less for smaller systems.

Follow the safety precautions outlined in “System Charging” on page 5.

8. Check fans and blowers for correct direction of rotation, belt tension, and proper air

flow (CFM).

9. With the protective terminal cover securely fastened, run the compressor and allow

the system pressures and temperatures to stabilize. Systems vary in their operating

characteristics, but generally these approximations will apply:

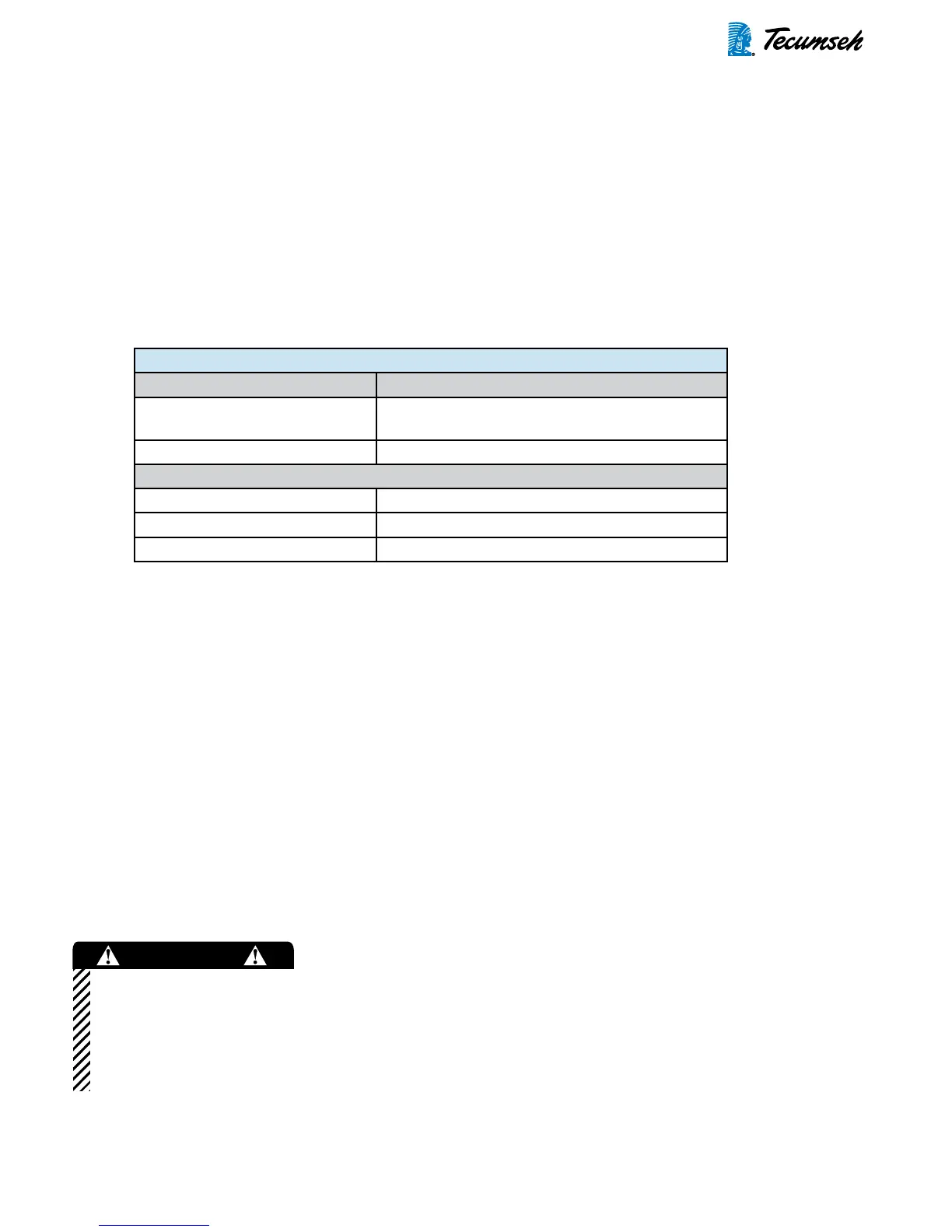

Table 5-6: Pressure and Temperature Stabilization

Pressure Temperature

Saturated head pressure Ambient temperature °F + 20°F for air cooled

condenser

Water cooled Discharge water °F + 10°F

Saturated evaporator pressure

Air conditioning Discharge air °F -20°F

Medium temperature Product temperature -10°F to -12°F

Low temperature Product temperature -6°F to -8°F

10. Before leaving the job, run the system for a while. Listen for abnormal noises. Feel

the bottom crankcase housing and determine that it is warm. Is the compressor upper

housing sweating indicating that liquid refrigerant is reaching the compressor? Is the

return gas temperature at the compressor within proper limits for the application (i.e.

not too low to cause flooding or not too high to produce high discharge and motor

temperatures)? Recheck pressures, amps, fan motors, belts, CFM, etc.

System Cleanup and Compressor Replacement After Com-

pressor Failure

Once you determine that a compressor needs to be replaced, you must determine whether the

system has been contaminated. Compressor motor failure can lead to such contamination. (While

compressor motor failure is sometimes referred to as motor “burnout,” it does not mean that a fire

actually occurs inside a hermetic compressor.) Even small amounts of contamination must be

removed from the system to avoid damaging the replacement compressor. Therefore, it is impor-

tant to thoroughly clean a refrigeration/air conditioning system if system contamination is present.

Ifacompressormotorfailurehasoccurred,refrigerantormixturesofrefrigerantandoilin

thesystemcanbeacidicandcancausechemicalburns.Asalways,toavoidinjury,wear

appropriateprotectiveeyewear,glovesandclothingwhenservicinganairconditioningor

refrigerationsystem.Ifrefrigerantormixturesofrefrigerantandoilcomeincontactwithskin

oreyes,flushtheexposedareawithwaterandgetmedicalattentionimmediately.

The following outlines a process for compressor replacement and system clean-up for a system

equipped with a Tecumseh compressor. You should refer to the original equipment manufac-

turer’s (OEM) service information.

!

WARNING

Loading...

Loading...