9

CHAPTER 2 AIR CLEANERS

TROUBLESHOOTING

If the engine's performance is unsatisfactory (needs

excessive adjustments, starts smoking abnormally, loses

power), the first component to be checked is the air

cleaner. A dirt restricted or an oil soaked filter element will

cause noticeable performance problems. A polyurethane

element may be cleaned following the service procedure

listed under "Service" in this chapter. A paper-type air filter

should only be replaced. Follow the procedure listed in the

service section in this chapter for replacement. Retry the

engine after filter replacement or service. If the problem

persists after filter service, additional solutions can be

found in Chapter 7 under "Troubleshooting".

SERVICE

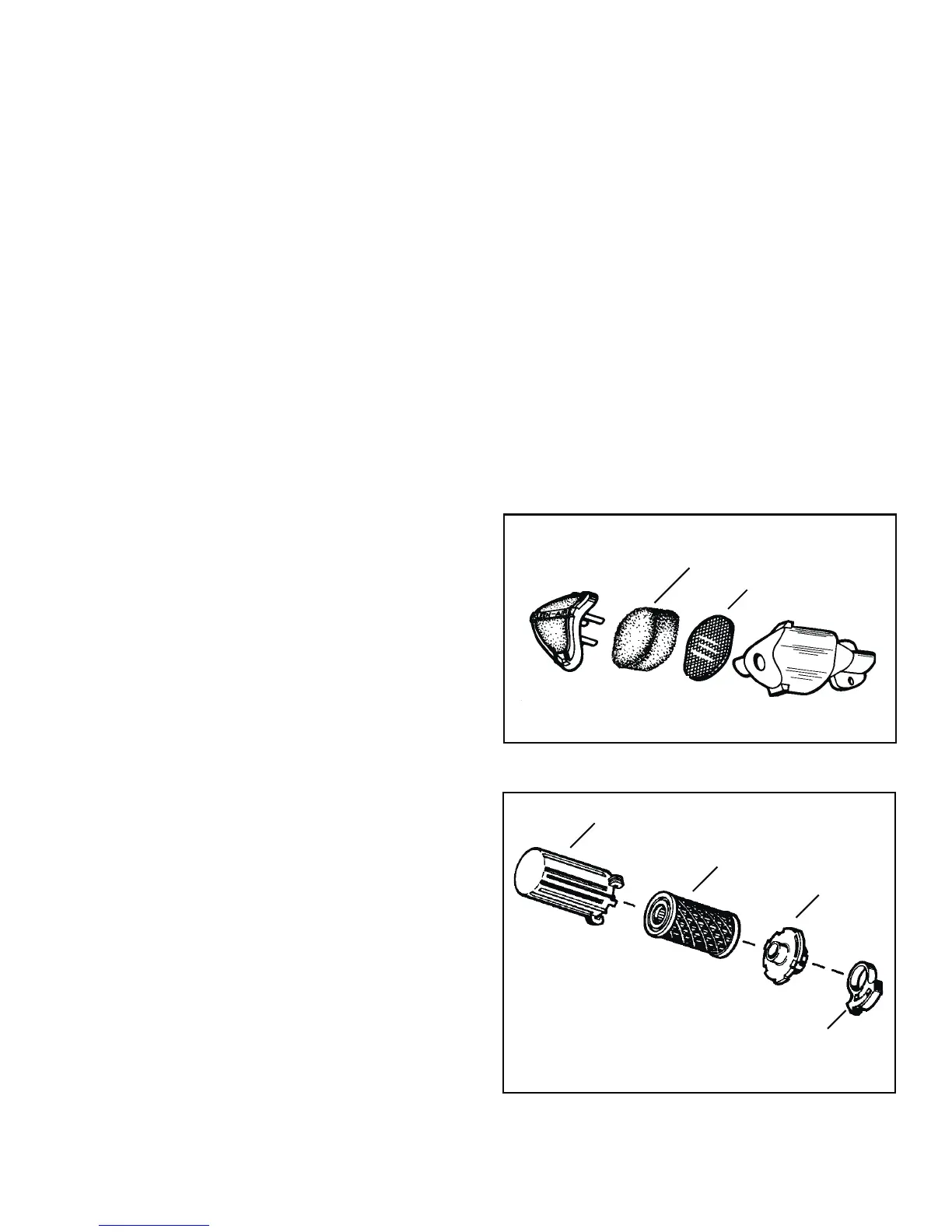

Cleaning and oiling the polyurethane element (diag. 2-1)

is recommended every three (3) months or every 25

operating hours. If the engine is used in extremely dusty

or dirty conditions, the filter may require service every

three hours or as often as necessary to maintain proper

engine performance.

Polyurethane type filters require re-oiling after extended

storage due to oil migration out of the filter.

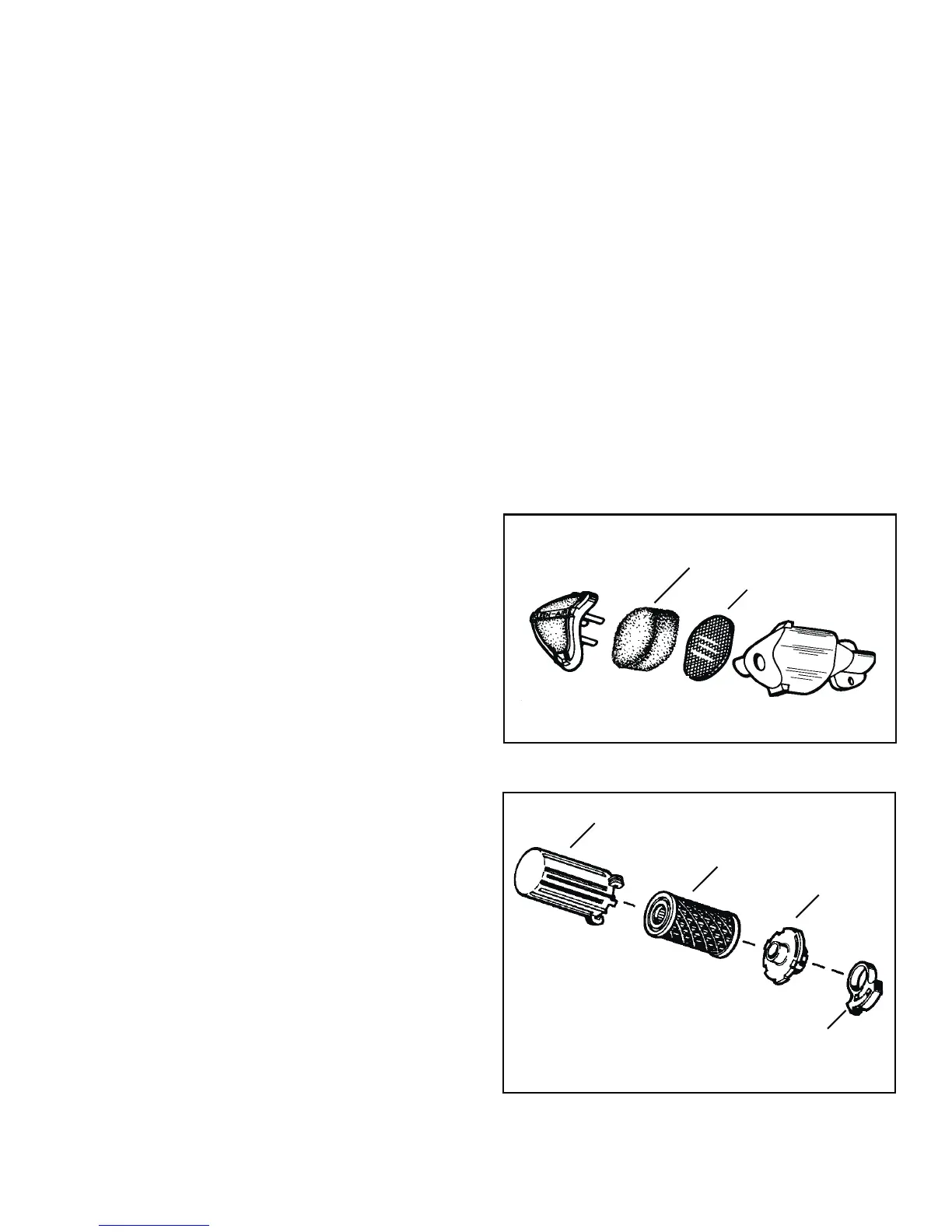

A paper type element (diag. 2-2) should be replaced once

a year, every 100 operating hours, or more often if used in

extremely dusty conditions. Use only original factory

recommended replacement filters.

NOTE

DO NOT attempt to clean or oil paper filters.

Air Cleaner Screen

Polyurethane Filter

2-1

2-2

Air Cleaner

Collar

Clamp

Cover

GENERAL INFORMATION

The air cleaner is designed to eliminate dust and dirt from the air supply. Most models of 2-cycle and 4-cycle engines

use an air cleaner except engines that run in clean environments like snow throwers or ice augers. On these

applications, a filter is not necessary and could collect snow or moisture and prevent proper engine operation. On most

applications, filtered air is necessary to assure abrasive particles are removed before entering the combustion chamber.

Dirt allowed into the engine will quickly wear the internal components and shorten the life of the engine.

Tecumseh engines use either a polyurethane or a paper type air filter system. A polyurethane pre-filter or a flocked

screen may be used in conjunction with the main filter. Extremely dirty operating conditions may require frequent filter

cleaning or replacement.

OPERATION

The outer cover holds the air filter element(s) and prevents debris from entering the filter box. The air supply is filtered

through the pre-filter if equipped, filter element (polyurethane or paper), and a flocked screen if equipped. Pre-filter

elements do not extend the recommended air filter service intervals listed under "Service". However; in extremely dirty

operating conditions a pre-filter element may increase the run time of the engine before the filter becomes restricted (not

to exceed the service recommendations), and service on the filter is necessary.

Loading...

Loading...