28

12

12

8

7

6

11

10

1

1

2

2

3

4

4

5

3

8

9

5-2

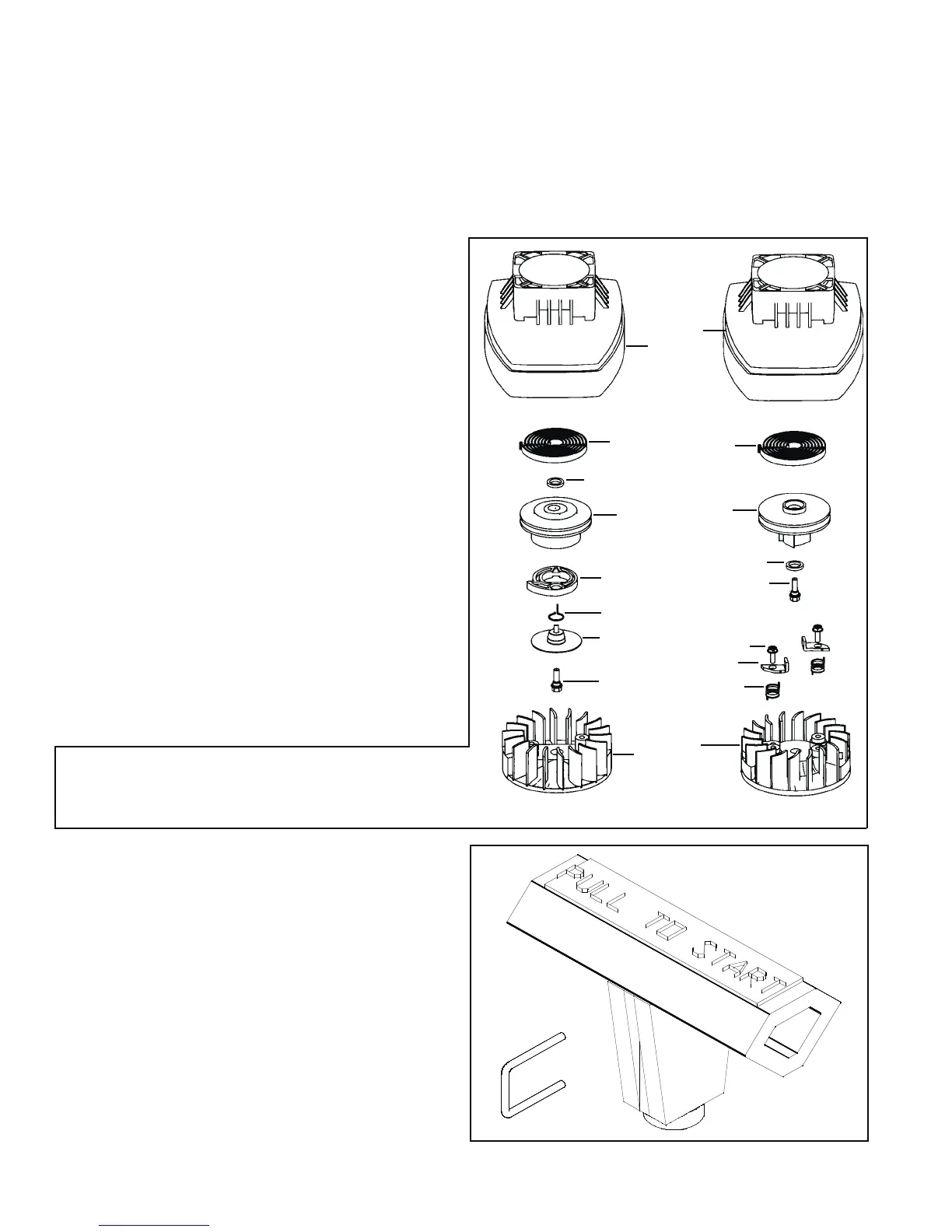

CHAPTER 5 REWIND STARTERS

GENERAL INFORMATION

TC/TM series engines have the recoil assembly as a part of the engine's blower housing. Two different styles of recoil

starters are used along with different starter rope locations. Use the engine model and specification number to identify

the recoil style and correct replacement parts.

OPERATION

TC TYPE I

As the starter rope is pulled, the starter pulley rotates on

the center leg of the starter. The starter pawl is connected

to the starter pulley by an offset hole in the pawl and a

corresponding raised boss on the pulley. The pawl has an

oversized inside diameter which allows the pawl to be

pulled off center. The flat contact surface of the pawl

engages with one of the flywheel fins. This engagement

turns the flywheel until the engine fires and the flywheel

speed exceeds the speed of the starter pulley. The

flywheel fins push the pawl (using the ramp side) to the

disengaged position. The brake spring slows the pulley

and pawl from turning (diag. 5-1).

TC TYPE II/TM

This starter uses two engagement pawls bolted to the

flywheel with shoulder bolts. Each pawl uses an

engagement spring to keep the pawl in contact with the

pulley hub. The pawls lock into two of the four notched

surfaces located on the starter pulley when the starter

rope is pulled. When the engine fires and the flywheel

speed exceeds the speed of the starter pulley, the pawls

disengage, and centrifugal force keeps the pawls in the

disengaged position (diag. 5-1).

COMPONENTS

1. Blower Housing

2. Recoil Spring

3. Washer

4. Pulley

5. Pawl

6. Brake Spring

7. Retainer

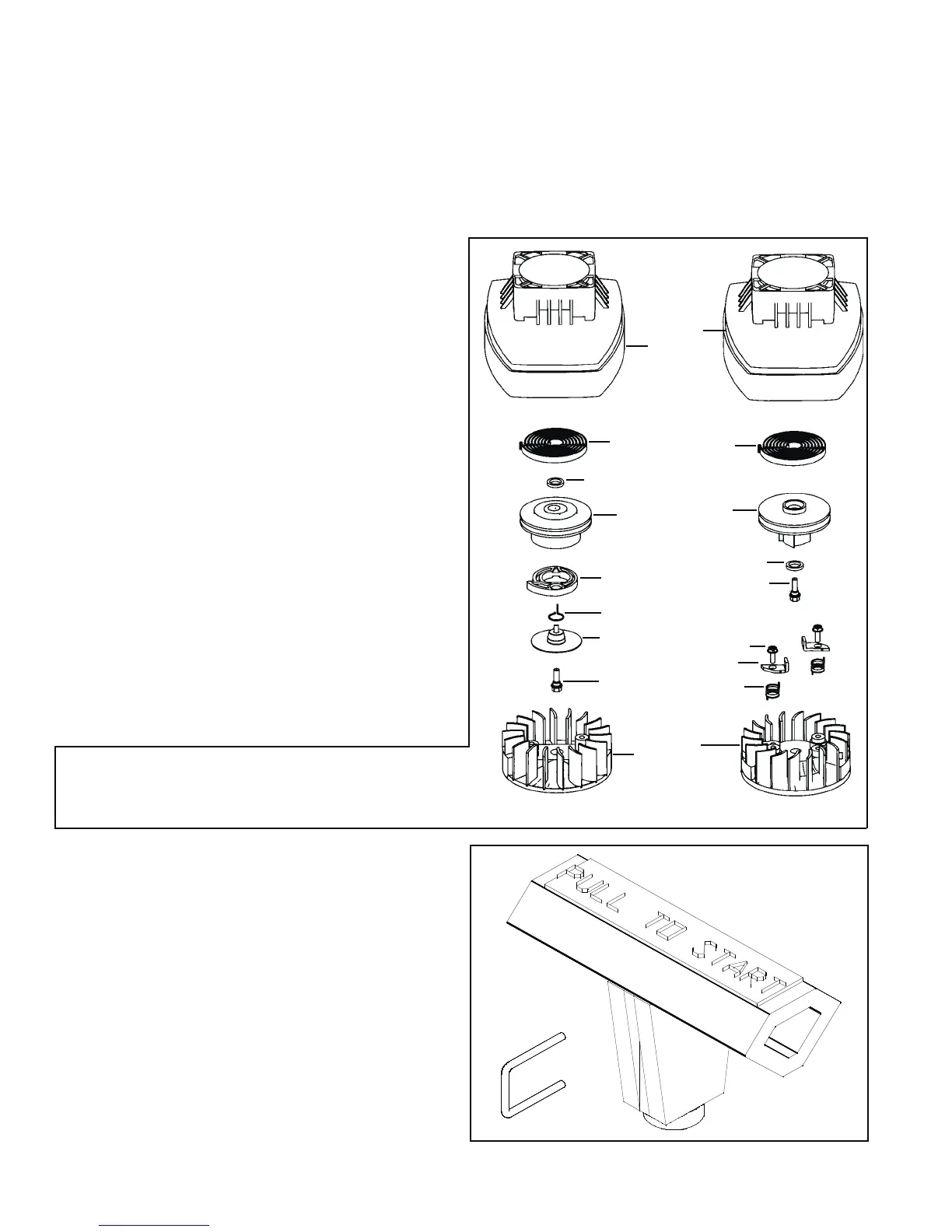

SERVICE

Starter related problems will require the starter to be

removed from the engine to diagnose the cause. On TC

Type I engines, try starter operation off the engine to see

pawl engagement. Visually inspect the starter pawl, brake

spring, retainer, pulley, washer(s) and rope for wear or

breakage. Repair or replace as necessary. On TC Type II/

TM engines, recoil disassembly is necessary only if the

pulley is worn, the recoil will not retract, or the rope needs

replacement. Check starter pawl engagement on the

flywheel for broken springs, sticking or bent condition, or

loose pawl screws.

DISASSEMBLY PROCEDURE

1. Remove the fuel tank spring and recoil assembly

from the engine. On TC Type II/TM engines, the air

filter and fuel tank must be removed before the

recoil assembly.

5-1

TC Type II/TM

TC Type I

8. Retainer Screw

9. Dog Screw

10. Starter Dog

11. Pawl Spring

Loading...

Loading...