10

108

Bolt

109

Curved Washer

LEFT/RIGHT

REVISIONS

ENGR

DATE

REV

SHT

ZONE

DESCRIPTION

NMS

10/18/2017

A

1

8D A1: RELEASE FOR PATENT

PARTS LIST

ITEM

QTY

NET DIMENSIONS/DESCRIPTION

NOTE

MATERIAL

SHT

REVISION STATUS

SHT

1

REV

A

8

A

1234567

D

C

B

C

A

D

B

5 3 16 248 7

8

A

1234567

D

C

B

C

A

D

B

5 3 16 248 7

handle assy

SHEET 1 OF 1

REV

PROJECT:

DRAWN

UNLESS OTHERWISE NOTED

SURFACE ROUGHNESS PER ANSI B46.1

DIMENSIONING PER ASME Y14.5-2009

WELD SYMBOLS PER AWS A2.4

FINISH:

UOS 63RMS ON

MACHINED

SURFACES OR

AS PROCURED

.X

.XX

.XXX

ANGLE

EXPECTATIONS PROPRIETARY

THE INFORMATION CONTAINED HEREIN

IS PROPRIETARY TO EXPECTATIONS AND

SHALL NOT BE REPRODUCED IN WHOLE

OR IN PART OR USED FOR ANY PURPOSE

EXCEPT WHEN SUCH USER POSSESSES

DIRECT WRITTEN AUTHORIZATION

FROM EXPECTATIONS LLC

SCALE: FULL

SIZE:

D

A

TOLERANCES

UNLESS NOTED

=

.1

=

.03

=

.005

=

1

NICK SOLLER

FILLET RADII: .005-.010

CORNER BREAK: .005-.010

ALL DIMENSIONS IN INCHES

EXPECTATIONS LLC

PUYALLUP, WA 98391

DRAWING

PROJECT NAME HERE

LEFT / RIGHT

Handle Support Tube Installation

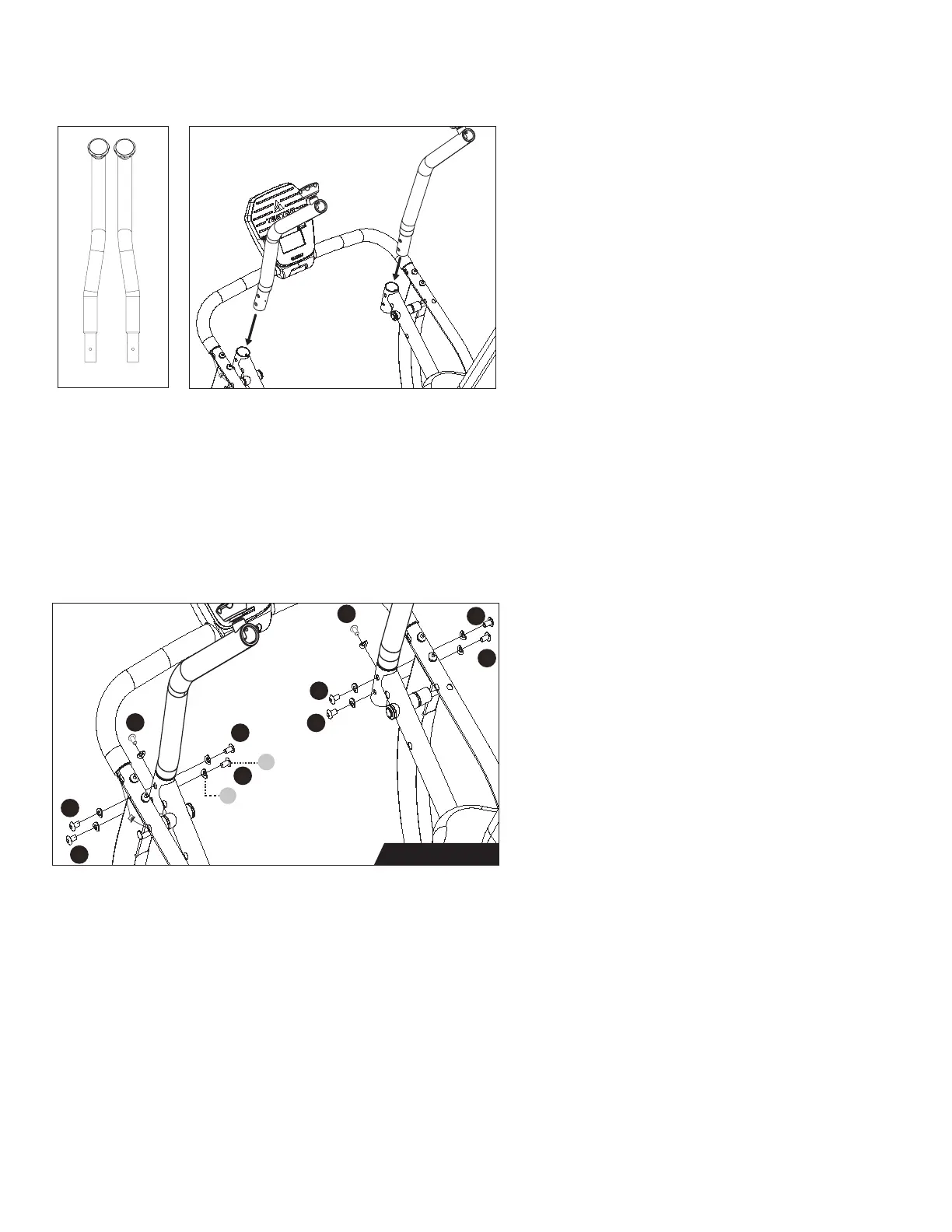

Figure 16a-16b: Locate the Handle Support

Tubes, noting Right and Left markings.

Insert the bottom of each Handle Support

Tube into the top of the Upper Pedal Arm.

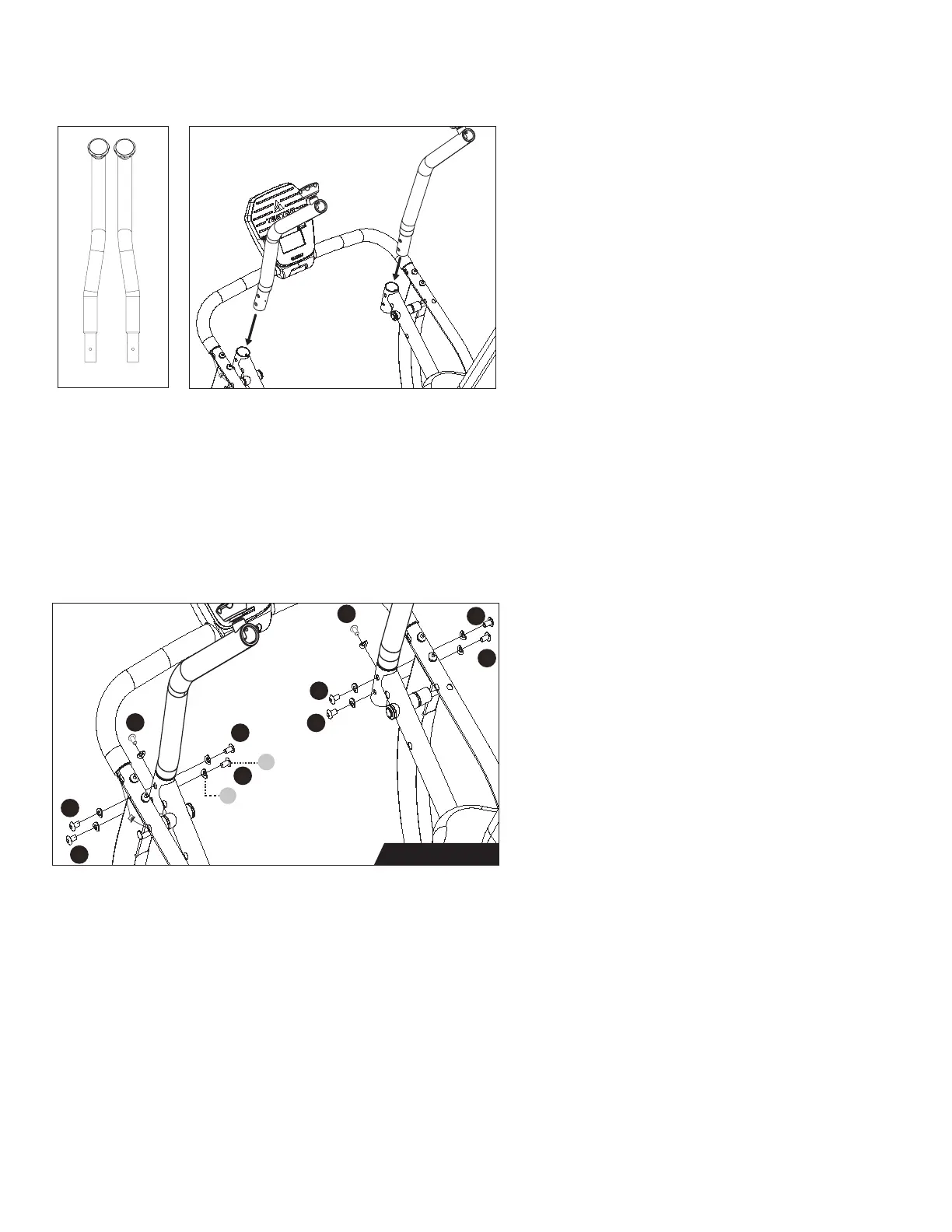

Figure 17: Use the Step 4b Hardware Kit

to attach the Handle Support Tubes.

IMPORTANT: Very loosely install 10 x Bolts

with 10 x Curved Washers 2-3 turns. The

Curved Washers should wrap around

the shape of the Upper Pedal Arms.

After all hardware has been installed 2-3

turns, there should still be 1-2 washer

thicknesses of space between the washer

and the base metal. This is important for

the next step so that the Handle Support

Tubes properly move into place as the

hardware is fully tightened. Proceed to

tighten all 10 Bolts in the EXACT order as

shown with the numbers in Figure 17 with

the Allen Wrench.

Figure 16bFigure 16a

Step 4b Hardware

Figure 17

1

2

5

3

4

9

8

10

6

7

Loading...

Loading...