Calibration—485/R485 Service

3. ADJUST TRACE ROTATION

a. Position trace to graticule center.

b. Adjust TRACE ROTATION (rear panel) so trace

parallels the center graticule line.

4. CHECK B SWEEP TIMING ACCURACY

a. Check timing over center eight graticule divisions.

b. Position one time mark to 1 and read error at 9.

NOTE

+ 15°Cto +35° C

-15 °C to + 55 °C

1 ns to 20 ns; within 0.24

division (3%)

0.4 div (5%)

50 ns to 0.1 s; within 0.16

division (2%)

0.32 div (4%)

0.2 s and 0.5 s; within 0.24

division (3%)

0.4 div (5%)

5. CHECK A SWEEP TIM ING ACCURACY

NOTE

+ 15°Cto+35°C

— 75°C to +55° C

1 ns to 20 ns; within 0.24

division (3%)

0.4 div (5%)

50 ns to 0.1 s; within 0.16

division (2%)

0.32 div (4%)

0.2 s to 0.5 s; within 0.24

division (3%)

0.4 div (5%)

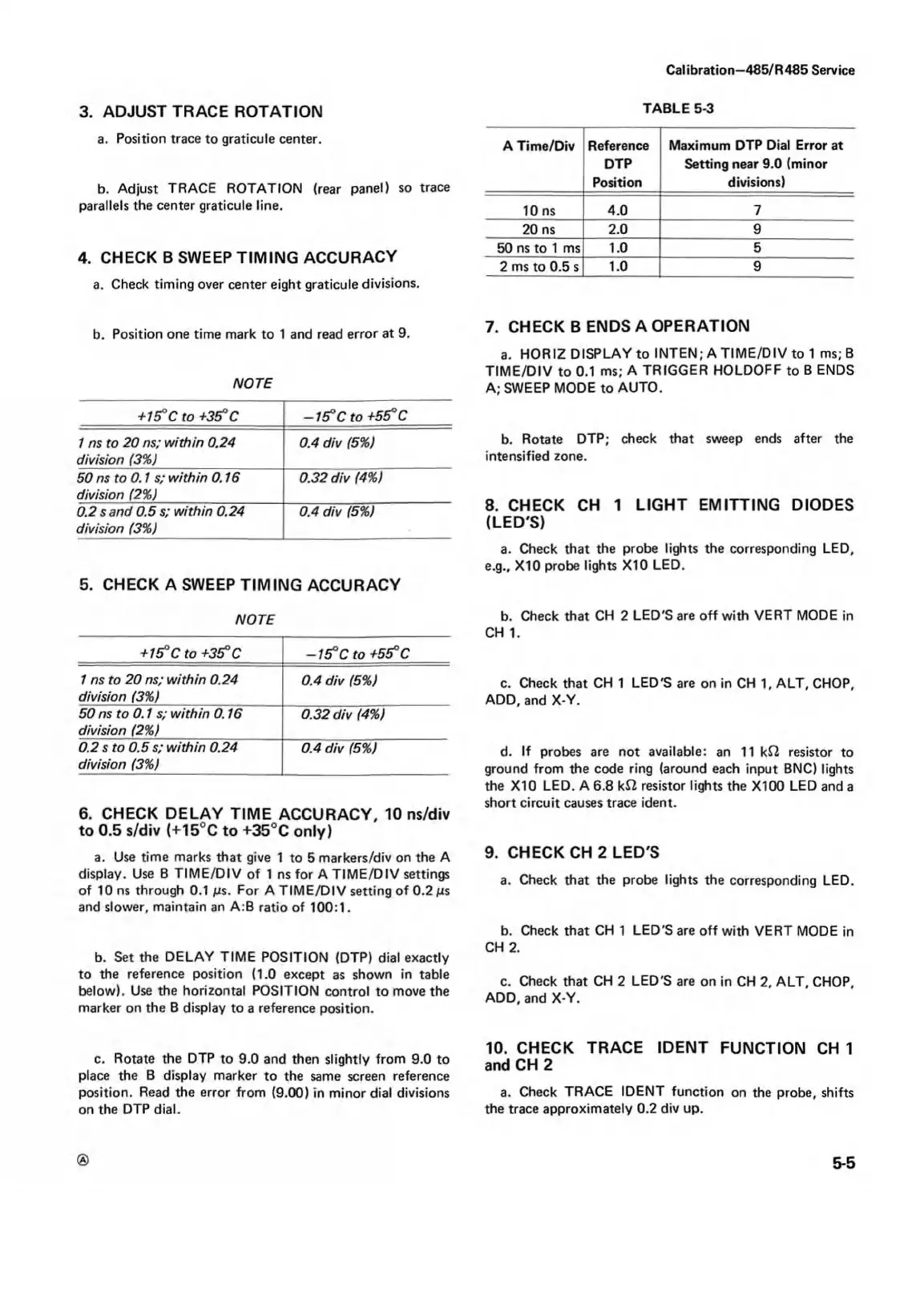

6. CHECK DELAY TIME ACCURACY, 10 ns/div

to 0.5 s/div (+15°C to +35°C only)

a. Use time marks that give 1 to 5 markers/div on the A

display. Use B TIME/DIV of 1 ns for A TIME/DIV settings

of 10 ns through 0.1 ps. For A TIME/DIV setting of 0.2 ps

and slower, maintain an A:B ratio of 100:1.

b. Set the DELAY TIME POSITION (DTP) dial exactly

to the reference position (1.0 except as shown in table

below). Use the horizontal POSITION control to move the

marker on the B display to a reference position.

c. Rotate the DTP to 9.0 and then slightly from 9.0 to

place the B display marker to the same screen reference

position. Read the error from (9.00) in minor dial divisions

on the DTP dial.

TABLE 5-3

A Time/Div

Reference

DTP

Position

Maximum DTP Dial Error at

Setting near 9.0 (minor

divisions)

10 ns

4.0

7

20 ns

2.0 9

50 ns to 1 ms

1.0 5

2 ms to 0.5 s

1.0 9

7. CHECK B ENDS A OPERATION

a. HORIZ DISPLAY to INTEN; A TIME/DIV to 1 ms; B

TIME/DIV to 0.1 ms; A TRIGGER HOLDOFF to B ENDS

A; SWEEP MODE to AUTO.

b. Rotate DTP; check that sweep ends after the

intensified zone.

8. CHECK CH 1 LIGHT EMITTING DIODES

(LED'S)

a. Check that the probe lights the corresponding LED,

e.g., X10 probe lights X10 LED.

b. Check that CH 2 LED'S are off with VERT MODE in

CH 1.

c. Check that CH 1 LED'S are on in CH 1, ALT, CHOP,

ADD, and X-Y.

d. If probes are not available: an 11 kJ2 resistor to

ground from the code ring (around each input BNC) lights

the X I0 LED. A 6.8 kJ2 resistor lights the X I00 LED and a

short circuit causes trace ident.

9. CHECK CH 2 LED'S

a. Check that the probe lights the corresponding LED.

b. Check that CH 1 LED'S are off with VERT MODE in

CH 2.

c. Check that CH 2 LED'S are on in CH 2, ALT, CHOP,

ADD, and X-Y.

10. CHECK TRACE IDENT FUNCTION CH 1

and CH 2

a. Check TRACE IDENT function on the probe, shifts

the trace approximately 0.2 div up.

5-5

Loading...

Loading...