Calibration—485/R485 Service

HORIZ DISPLAY to INTEN; B TRIGGER SOURCE to B

RUNS AFTER DELAY TIME.

b. Trigger A on + SLOPE. Use DELAY TIME POSITION

control to position the intensified portion of the negative

step near center screen.

c. Switch HORIZ DISPLAY to B and position the

negative step to center screen.

d. Switch A SLOPE polarity and check that the

transition changes less than 3 divisions horizontally.

24. CHECK DELAY JITTER

a. Set A TIME/DIV to 1 ms; B trigger source to B RUNS

AFTER DELAY TIME. Set B TIME/DIV to 1 ps and

Time-Mark generator to 1 ms. Set HORIZ DISPLAY to

ALT; use A trigger LEVEL to obtain a stable display.

b. Set HORIZ DISPLAY to B. Rotate DELAY TIME

POSITION dial from 1 to 9, checking for 0.5 div of jitter or

less on B display.

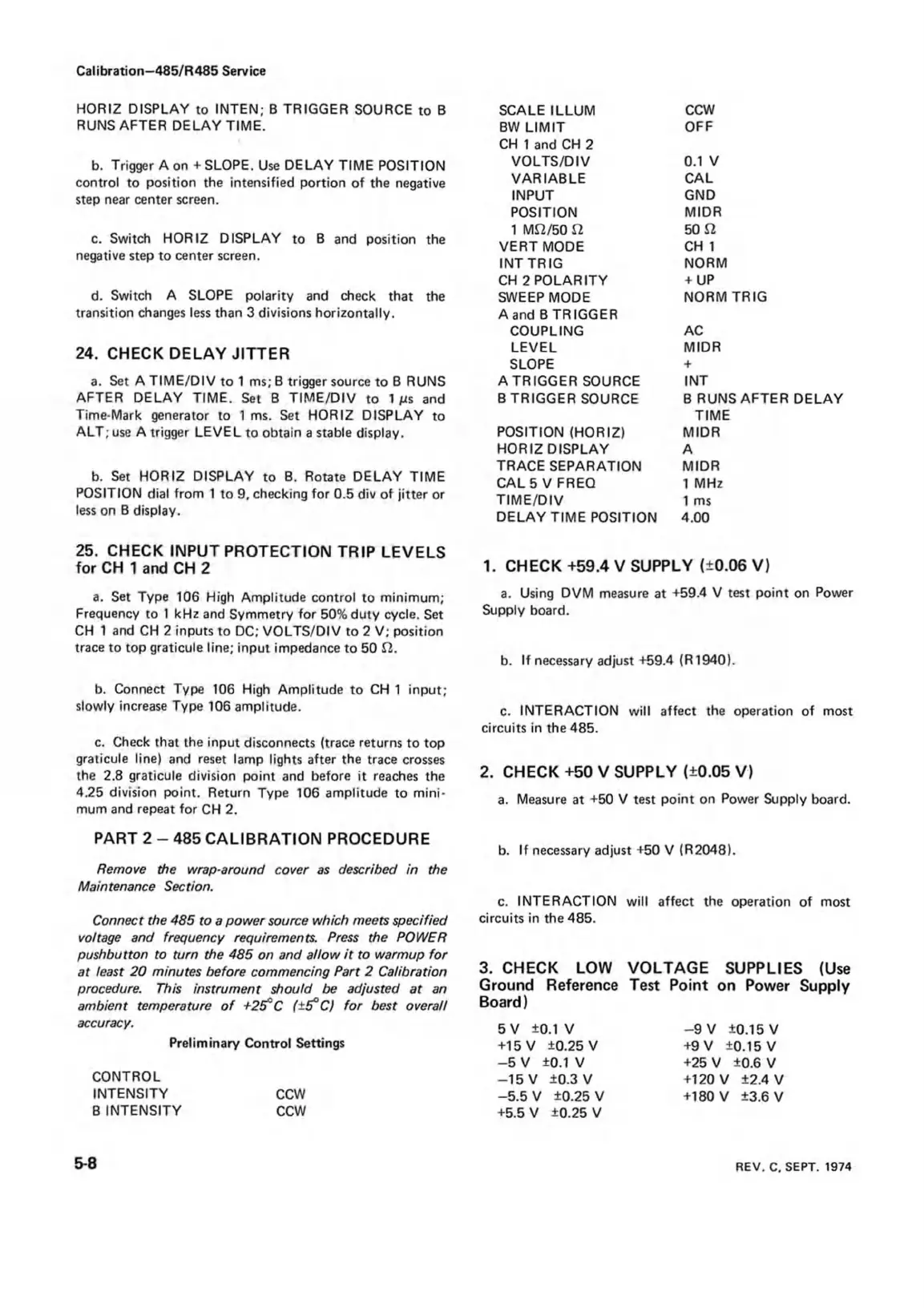

SCALE ILLUM

CCW

BW LIMIT

CH 1 and CH 2

OFF

VOLTS/DIV 0.1 V

VARIABLE

CAL

INPUT

GND

POSITION

MIDR

1 Mft/50 ft

50 ft

VERT MODE

CH 1

INTTRIG

NORM

CH 2 POLARITY

+ UP

SWEEP MODE

A and B TRIGGER

NORM TRIG

COUPLING

AC

LEVEL

MIDR

SLOPE

+

A TRIGGER SOURCE

INT

B TRIGGER SOURCE B RUNS AFTER DELAY

TIME

POSITION (HORIZ) MIDR

HORIZ DISPLAY A

TRACE SEPARATION

MIDR

CAL 5 V FREQ 1 MHz

TIME/DIV

1 ms

DELAY TIME POSITION

4.00

25. CHECK INPUT PROTECTION TRIP LEVELS

for CH 1 and CH 2

a. Set Type 106 High Amplitude control to minimum;

Frequency to 1 kHz and Symmetry for 50% duty cycle. Set

CH 1 and CH 2 inputs to DC; VOLTS/DIV to 2 V; position

trace to top graticule line; input impedance to 50 ft.

b. Connect Type 106 High Amplitude to CH 1 input;

slowly increase Type 106 amplitude.

c. Check that the input disconnects (trace returns to top

graticule line) and reset lamp lights after the trace crosses

the 2.8 graticule division point and before it reaches the

4.25 division point. Return Type 106 amplitude to mini

mum and repeat for CH 2.

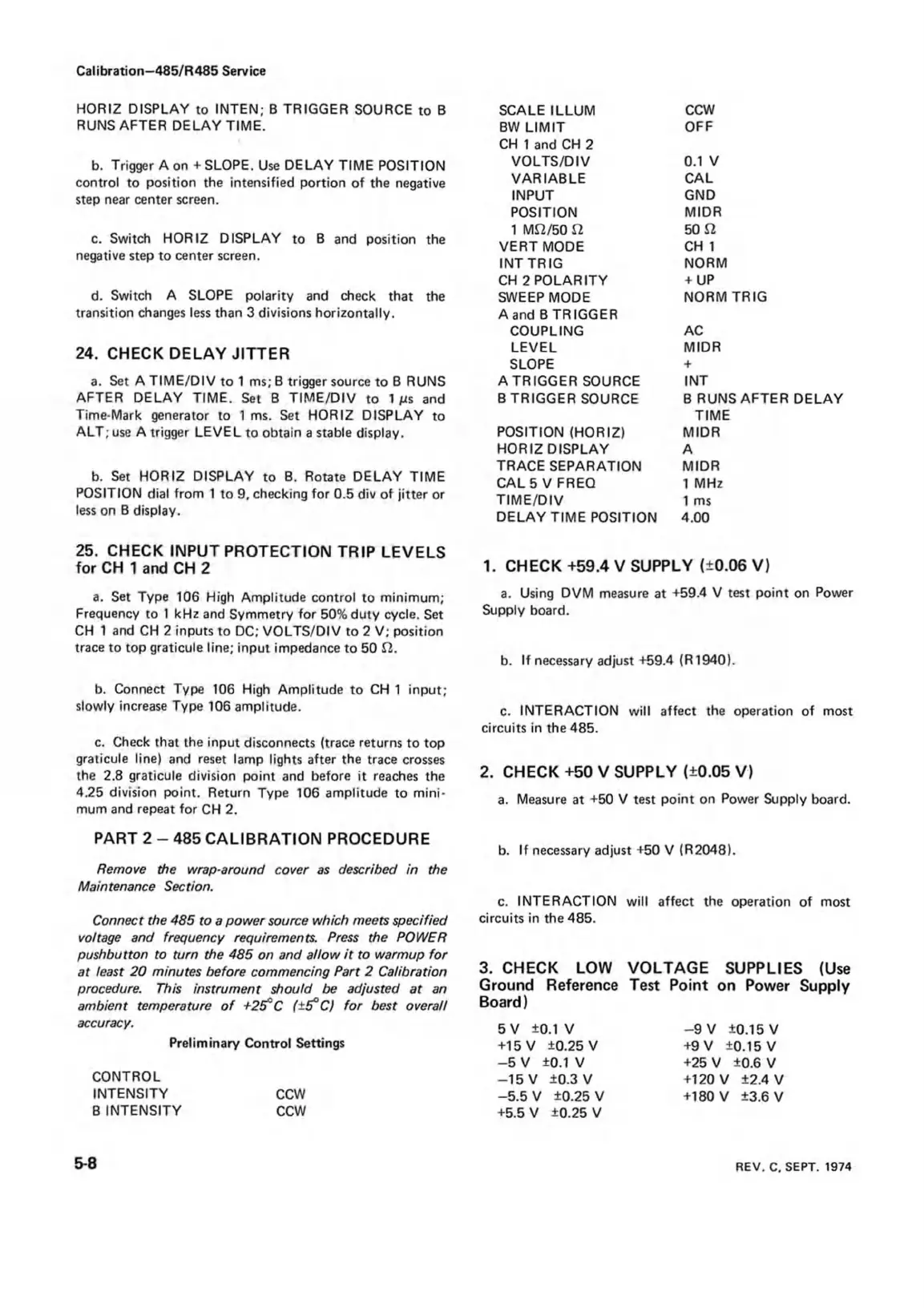

1. CHECK +59.4 V SUPPLY (±0.06 V)

a. Using DVM measure at +59.4 V test point on Power

Supply board.

b. If necessary adjust +59.4 (R1940).

c. INTERACTION will affect the operation of most

circuits in the 485.

2. CHECK +50 V SUPPLY (±0.05 V)

a. Measure at +50 V test point on Power Supply board.

PART 2 - 485 CALIBRATION PROCEDURE

Remove the wrap-around cover as described in the

Maintenance Section.

Connect the 485 to a power source which meets specified

voltage and frequency requirements. Press the POWER

pushbutton to turn the 485 on and allow it to warmup for

at least 20 minutes before commencing Part 2 Calibration

procedure. This instrument should be adjusted at an

ambient temperature o f +25°C f±5°C) for best overall

accuracy.

Preliminary Control Settings

CONTROL

INTENSITY CCW

B INTENSITY CCW

b. If necessary adjust +50 V (R2048).

c. INTERACTION will affect the operation of most

circuits in the 485.

3. CHECK LOW

Ground Reference

Board)

5 V +0.1 V

+15 V +0.25 V

-5 V ±0.1 V

-15 V ±0.3 V

-5.5 V ±0.25 V

+5.5 V ±0.25 V

Point on Power Supply

—9 V ±0.15 V

+9 V ±0.15 V

+25 V ±0.6 V

+120 V ±2.4 V

+180 V ±3.6 V

VOLTAGE SUPPLIES (Use

Test

5-8

REV. C, SEPT. 1974

Loading...

Loading...