4-4

(7) If the liquid level is lowered, the pump takes air in, thus decreasing the delivery volume and

disabling pumping-up. The liquid level should be above the lowest liquid level indicated in the

outline drawing. However, this liquid level changes depending on dynamic viscosity and the

liquid level condition. For safety, set the liquid level high enough. However, the liquid level

should not exceed the "highest liquid level" indicated in the outline drawing.

(8) Limit the startup and stop frequencies to 60 times per hour as a guide.

Caution

Minimize the frequency of startups and shutdowns of the pump as it may

lead to premature damage to the pump. Do not start the pump more than

60 times an hour.

(9) If a power failure occurs during operation, be sure to turn off the power.

Warning

In the event of a power failure, be sure to turn off the power.

The pump may be suddenly started at the recovery from a power failure,

which leads to a danger.

(10) Before restarting the pump, confirm that the pump is at a complete stop.

Caution

After power-off, do not restart the pump until it comes to a complete stop.

Otherwise, an excessive load may act on the pump shaft, resulting in

shortened service life of the pump. Start the pump from a complete stop.

(11) Avoid abrupt pressure fluctuations during pump operation.

(12) Check for any abnormal pressure, current, vibration, noise, and other conditions. If you find an

abnormality, take appropriate action after reading Section 6 "Troubleshooting".

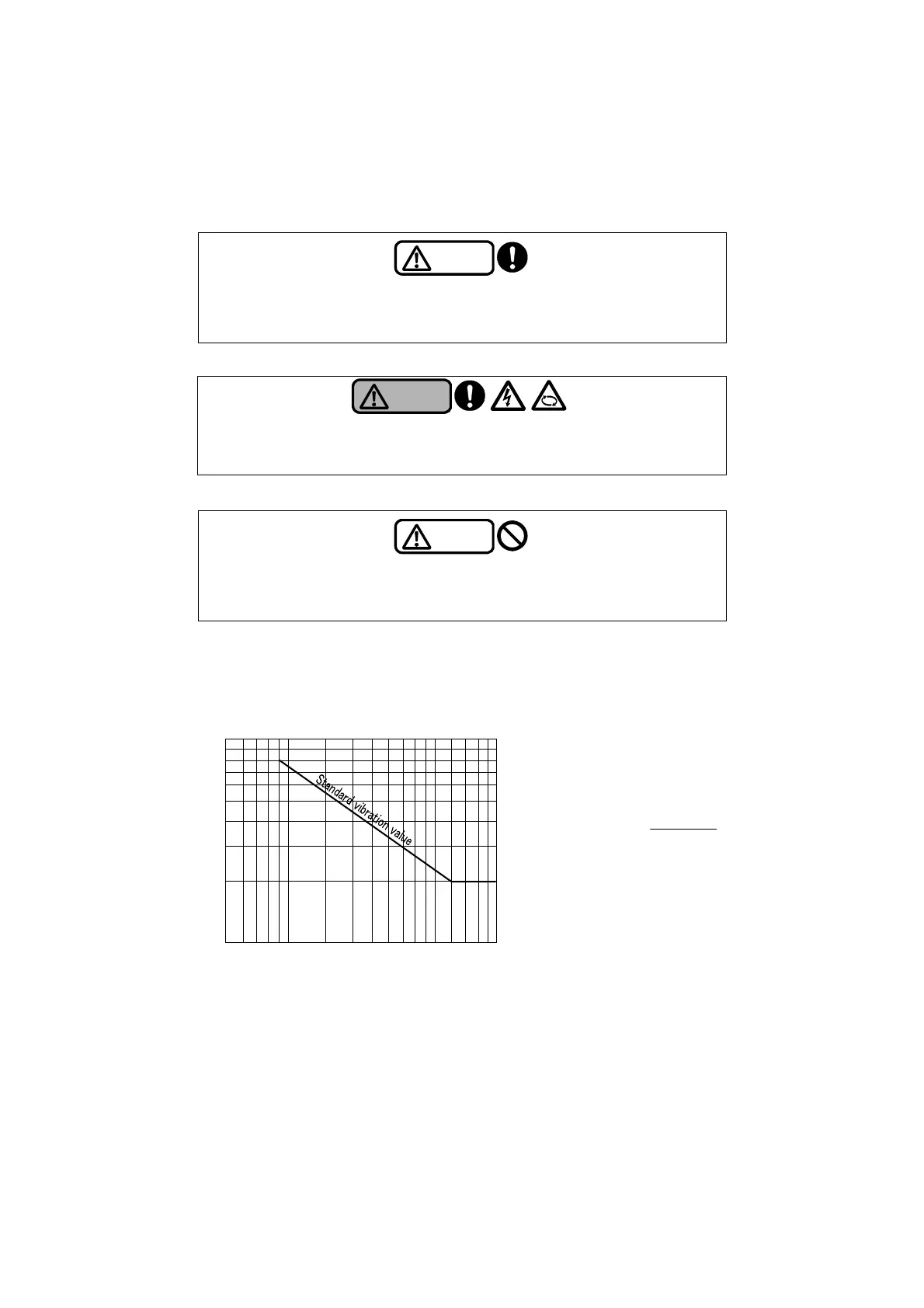

Refer to the following for vibration.

Standard vibration value at the bearing section

<Reference>

Relational expression between total

amplitude a and vibration velocity V

a =

V×4×10

4

π×n

a: Total amplitude (μm)

V: Vibration velocity (mm/s)

n: Equipment rotation speed (min-1)

(13) Do not allow a large amount of cutting powder to get in the pump. Failure to observe this may

clog the pump strainer, break the pump, or promote the performance degradation. If you use

the pump in the grinding process and other processes, e.g. milling and end milling, which

discharge cutting powder, select a pump carefully.

80

60

40

20

10

600 800 1000 1500 2000 3000 4000 6000 8000

100

Rotation speed (min

-

)

Total amplitude

(1/1000mm)

Loading...

Loading...