TROUBLESHOOTING

2-3

Page 1

ML50-30 MAINTENANCE LIFT

TESCO EQUIPMENT LLC

Section 3: Troubleshooting

1. GENERAL INFORMATION

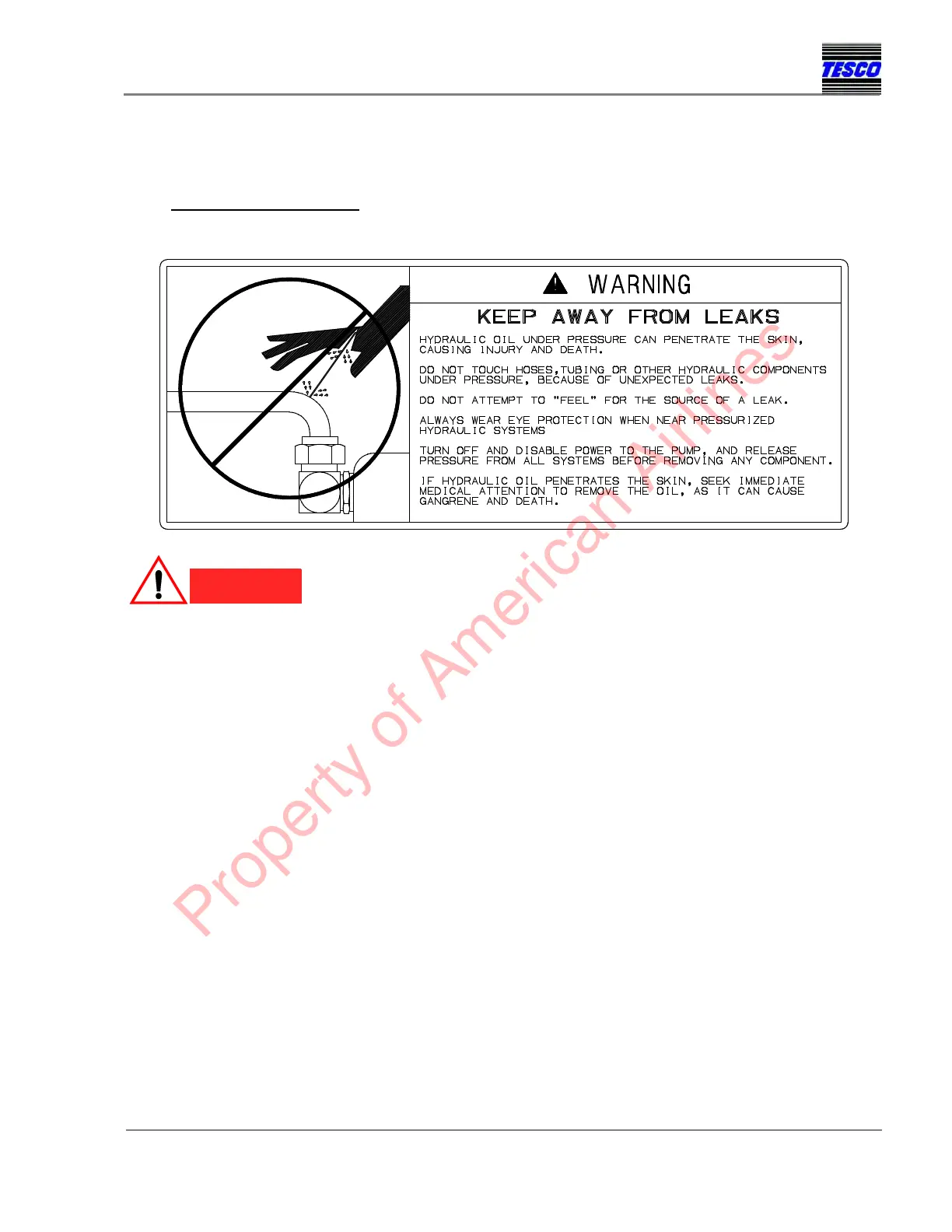

WARNING

ONLY QUALIFIED TECHNICIANS, WHO HAVE BEEN TRAINED IN THE USE AND OPERATION

OF THIS EQUIPMENT, SHOULD ATTEMPT ANY TROUBLESHOOTING. THE CHASSIS WHEELS

MUST BE CHOCKED TO PREVENT THE HI-LIFT UNIT FROM MOVING IN EITHER DIRECTION.

THE MAINTENANCE PROP MUST BE INSTALLED FOR SUPPORT WHENEVER THE

PLATFORM IS RAISED FOR MAINTENANCE OR ADJUSTMENTS. FAILURE TO FOLLOW GOOD

SAFETY PRACTICES DURING MAINTENANCE OR TROUBLESHOOTING COULD RESULT IN

DEATH OR SERIOUS INJURY TO PERSONNEL AND/OR DAMAGE TO EQUIPMENT.

The information contained in this section is provided as a guide to assist technical service personnel in

troubleshooting operational malfunctions in the ML5-30 Lift Unit hydraulic and electrical systems.

1. Before starting troubleshooting procedures, verify that the correct operating procedures were

used. An incorrect operating procedure can cause apparent malfunctions.

2. The most important practice to observe when working on the hydraulic system is cleanliness.

Serious damage can result quickly from foreign material in the hydraulic system. When a

hydraulic system is opened, cap or plug all ports and openings to keep foreign material and

moisture-laden air from entering the system. DO NOT use Teflon tape or pipe compound on

straight threads.

NOTE: Refer to the troubleshooting chapter in the chassis manufacturer’s manual for chassis

troubleshooting instructions.

Aug. 05

Property of American Airlines

Loading...

Loading...