MAINTENANCE

2-1

Page 2

TESCO EQUIPMENT LLC

ML50-30 MAINTENANCE LIFT

CAUTION

AFTER PERFORMING MAINTENANCE ON THE HI-LIFT, DISPOSE OF ANY

ENVIRONMENTALLY SENSITIVE MATERIALS ACCORDING TO LOCAL ENVIRONMENTAL

REGULATIONS. EXAMPLES OF SUCH MATERIALS INCLUDE: BATTERIES, RUBBER BELTS,

LUBRICANTS (MOTOR OILS AND GREASE), AND HYDRAULIC OIL.

2. HYDRAULIC OIL RECOMMENDATIONS

The hydraulic oil reservoir is factory filled with ISO 15 hydraulic oil at the time of shipping.

SEVERE CLIMATE OPERATION

• If platform lowering becomes too slow in severe cold weather operations, a lower viscosity fluid

may be substituted.

3. CHECKING HYDRAULIC OIL LEVEL

Maintaining proper hydraulic oil level is important. DO NOT overfill the hydraulic oil reservoir. Hydraulic

oil expands when heated.

1. The hydraulic oil reservoir is equipped with a sight gauge. Ensure that the Hi-Lift is fully lowered

and stabilizers must be in stowed position when checking hydraulic oil level using the sight

gauge. The oil level should be near the “High” mark and must not be below the “Low” mark.

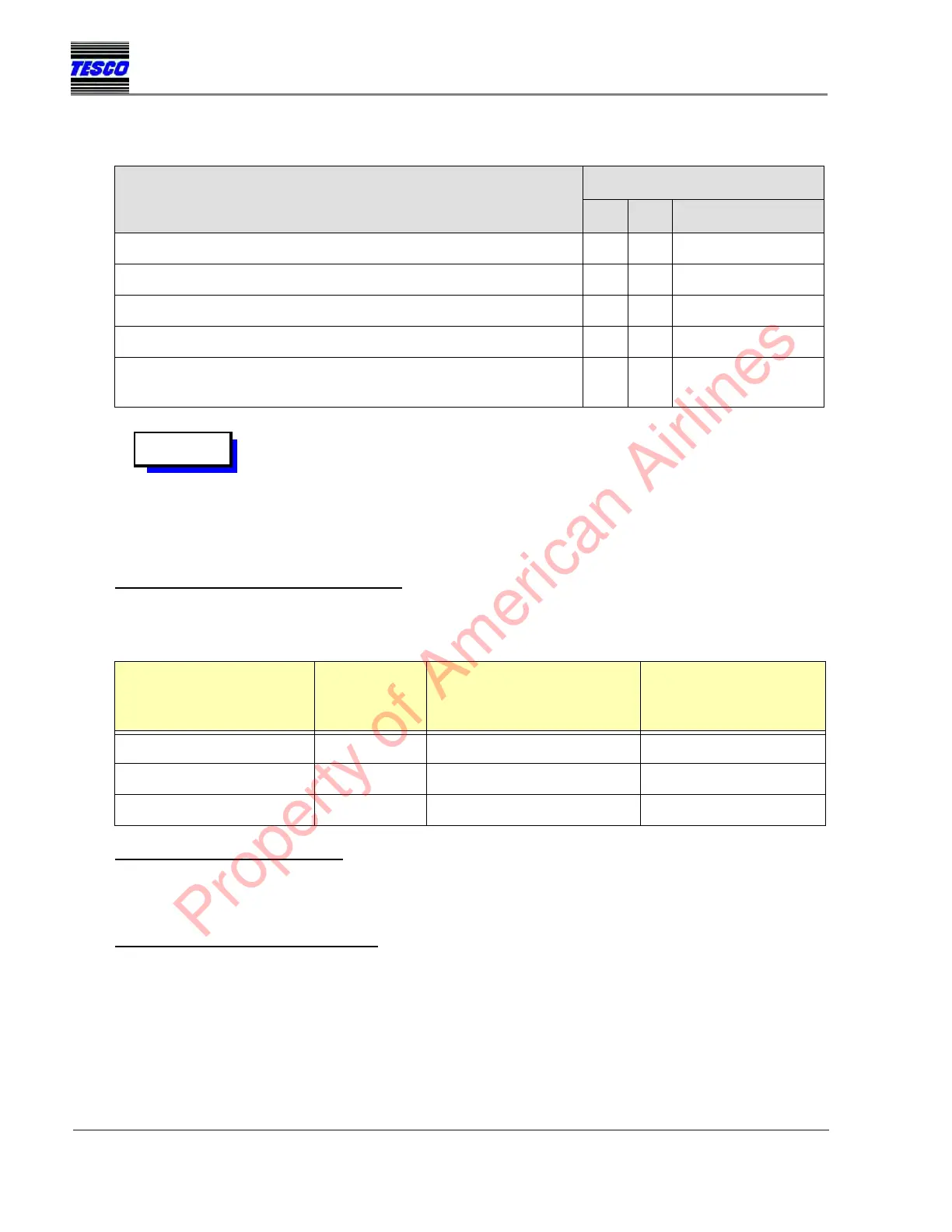

Replace return filter 6 mos.

Check that all wiring terminals are secure. 6 mos.

Replace corrosion inhibitor in main electrical control box. Annually

Drain hydraulic reservoir and clean. Annually

Check hoist rollers for wear X No more than

1/4” wear

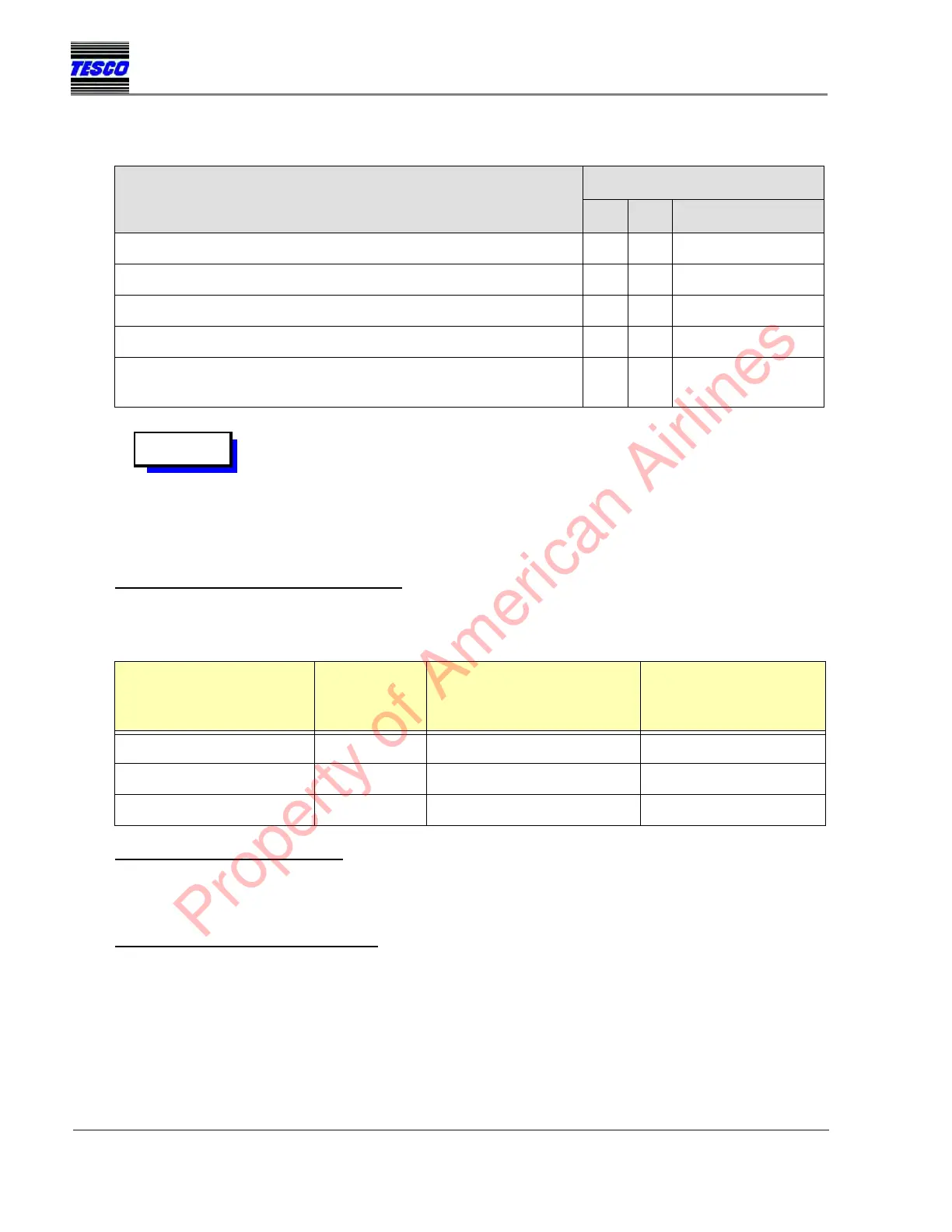

OIL OPERATING TEMPERATURE RANGE

RECOMMENDED

GRADE OF

HYDRAULIC FLUID

CLIMATE

AMBIENT

TEMPERATURE

MAXIMUM BULK OIL

(RESERVOIR

TEMP.)

ISO 32 Hot Above 60° F (15° C) 180° F (82° C)

ISO 15 Moderate 20° F (-7° C) -100° F (38° C) 165° F (74° C)

ISO 5 Cold Below 32° F (0° C) 150° F (60° C)

PERIODIC MAINTENANCE CHART

PROCEDURE

PERIOD (HOURS)

8 250 OTHER

Mar. 09

Property of American Airlines

Loading...

Loading...