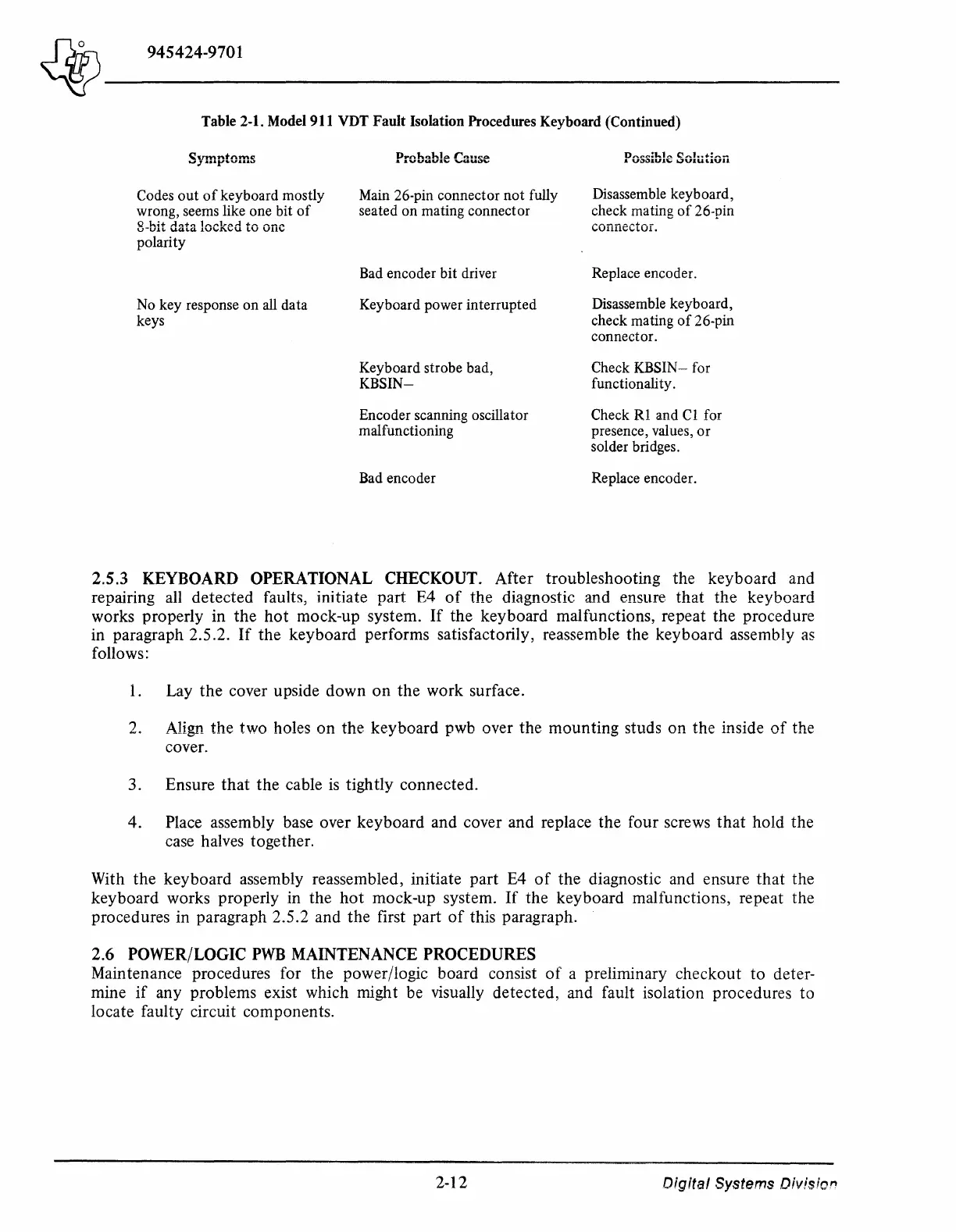

Table 2-1. Model 911 VDT Fault Isolation Procedures Keyboard (Continued)

~umntnmeo

._, J .a••y•vr•••"

Codes

out

of

keyboard mostly

wrong, seems like one bit

of

Q

h-i+

rln+n

1,

..

,,.J,..,.,.,.1

+,....

,....~,.

u-u.u

..

UQ.LQ.

J.V

.....

1'.VU

l.V

Vll\I

polarity

No key response on all data

keys

Probable Cause

Main 26-pin connector

not

fully

seated on mating connector

Bad encoder bit driver

Keyboard power interrupted

Keyboard strobe bad,

KBSIN-

Encoder scanning oscillator

malfunctioning

Bad encoder

Possible Solution

Disassemble keyboard,

check mating

of

26-pin

connector.

Replace encoder.

Disassemble keyboard,

check mating

of

26-pin

connector.

Check

KBSIN-

for

functionality.

Check

Rl

and

Cl

for

presence, values,

or

solder bridges.

Replace encoder.

2.5.3 KEYBOARD OPERATIONAL CHECKOUT.

After

troubleshooting

the

keyboard

and

repairing all

detected

faults, initiate

part

E4

of

the

diagnostic and ensure

that

the

keyboard

works

properly

in

the

hot

mock-up system.

If

the

keyboard

malfunctions, repeat

the

procedure

in paragraph 2.5 .2.

If

the

keyboard

performs satisfactorily, reassemble the

keyboard

assembly

as

follows:

1.

Lay

the

cover upside

down

on

the

work surface.

2. Align

the

two

holes

on

the

keyboard

pwb over

the

mounting

studs

on

the

inside

of

the

cover.

3. Ensure

that

the

cable is tightly

connected.

4. Place assembly base over

keyboard

and

cover and replace

the

four screws

that

hold

the

case halves together.

With

the

keyboard

assembly reassembled, initiate

part

E4

of

the

diagnostic and ensure

that

the

keyboard

works properly in

the

hot

mock-up system.

If

the

keyboard

malfunctions, repeat the

procedures in paragraph 2.5.2 and

the

first

part

of

this paragraph.

2.6

POWER/LOGIC

PWB

MAINTENANCE PROCEDURES

Maintenance procedures for the power/logic board consist

of

a preliminary

checkout

to

deter-

mine

if

any problems exist which might be visually

detected,

and fault isolation procedures

to

locate faulty circuit components.

2-12

o;gital

Systems

Division

Loading...

Loading...