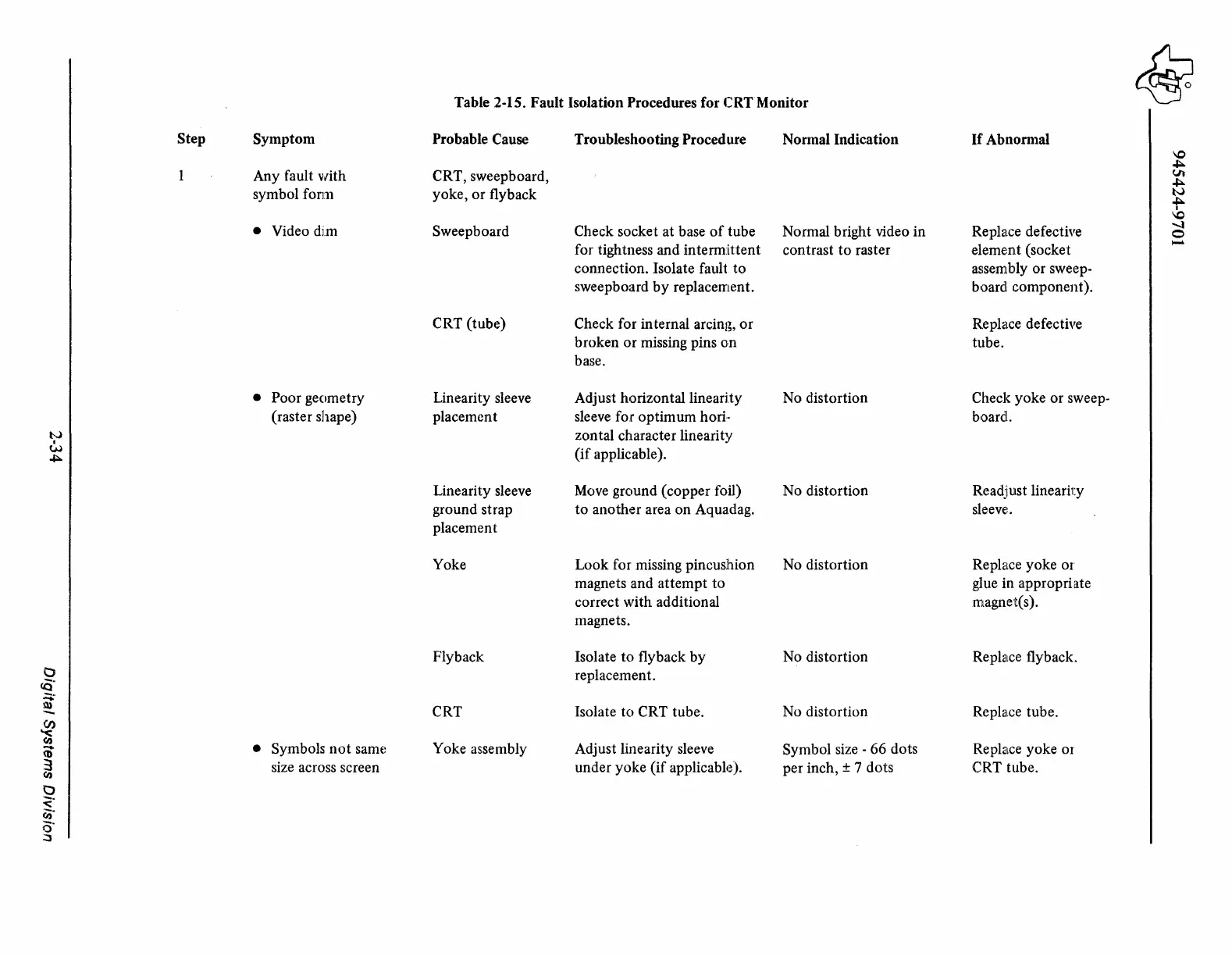

Table 2-15. Fault Isolation Procedures for CRTMonitor

~

Step

Symptom

Probable Cause Troubleshooting Procedure

Normal Indication

If

Abnormal

\0

+:-.

Any fault with

CRT, sweepboard,

Vt

+:-.

symbol form

yoke, or flyback

N

+:-.

I

\0

• Video dim

Sweepboard Check socket at base

of

tube

Normal bright video in Replace defective

-..J

0

for tightness and intermittent

contrast

to

raster

eleme:nt (socket

-

connection. Isolate fault

to

assembly or sweep-

sweepboard

by

replacement.

board!

component).

CRT (tube)

Check for internal arcing,

or

Rephtce defective

broken or missing pins

on

tube.

base.

• Poor geometry

Linearity sleeve Adjust horizontal linearity

No distortion

Check yoke or sweep-

(raster shape) placement sleeve for optimum hofi.·

board!.

t-..>

zontal character linearity

w

(if

applicable).

~

Linearity sleeve

Move

ground (copper foil) No distortion Readjust linearii:y

ground strap

to

another area on Aqua.dag.

sleeve:.

placement

Yoke Look for missing pincushion No distortion Replace yoke or

magnets and attempt

to

glue in appropriate

correct with additional

magnet(s).

magnets.

Fly back Isolate

to

flyback by No distortion

Replace flyback.

0

replacement.

<9:

~

CRT

(J)

Isolate

to

CRT tube. No distortion

Replalce

tube.

"<

(I)

Symbols

not

sam~:

Yoke assembly Adjust linearity sleeve

Symbol size - 66 dots

Replalce

yoke

01

(i)

•

3

size across screen under yoke

(if

applicable~).

per inch, ± 7 dots CRT tube.

(I)

0

<·

rn·

a·

~

Loading...

Loading...