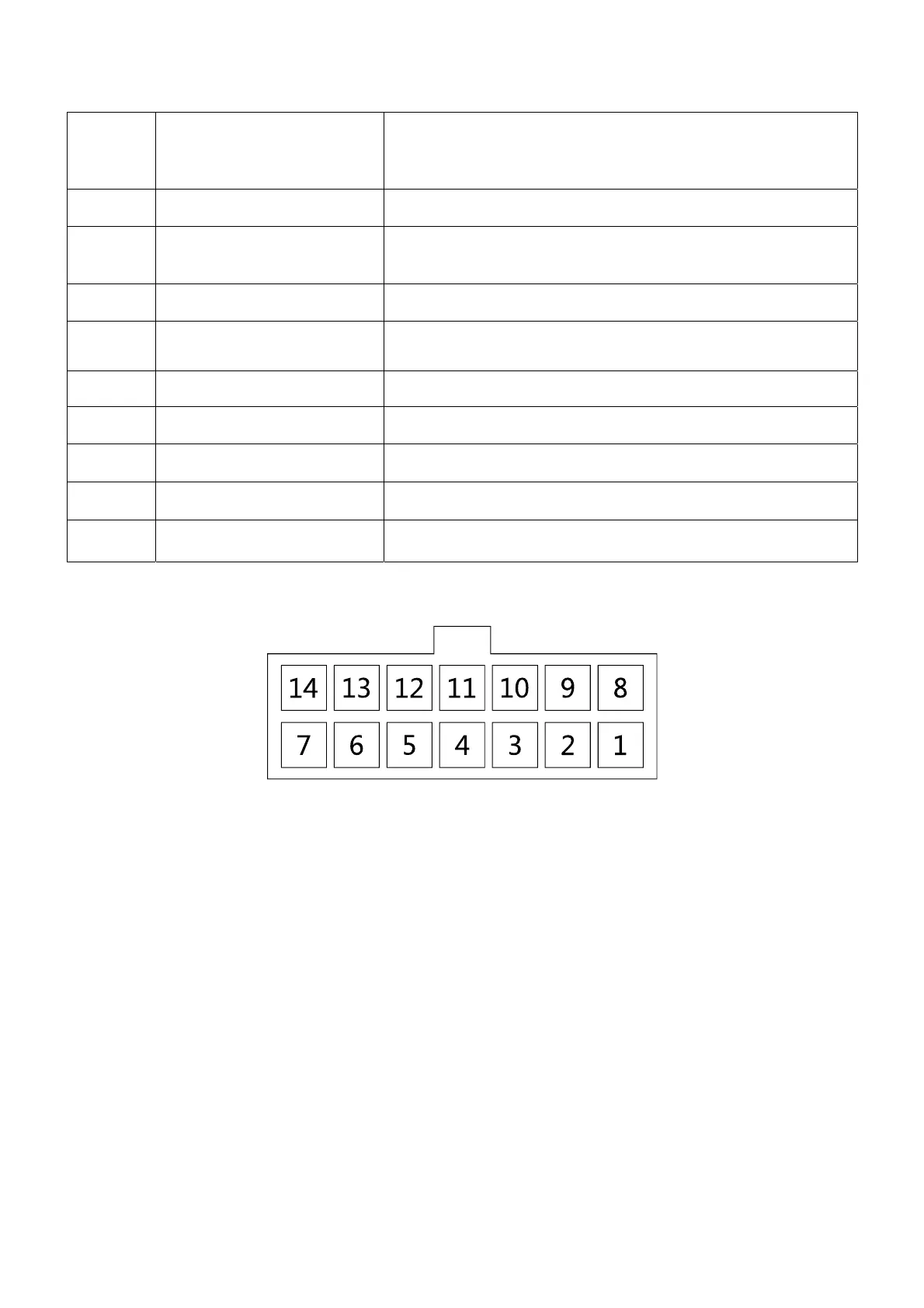

4 Port Diagram

12P Function Port Description

1. Thread trimming electromagnet: 1, 8 (+32V)

2. Thread wiping/ thread clamping electromagnet: 2, 9 (+32V)

3. Thread slacking electromagnet: 3, 10 (+32V)

4. LED Light: 4 (DGND), 11 (+5V)

5. Reverse stitch key: 5 (signal)

6. Mending stitch key: 7 (signal)

2P Function Port Description

E09

E11

Positioning signal error

Turn off the machine, please check if the encoder in bad connection or is too

loose. To get it right and turn on. If there are still errors, please replace the

control box and call for customer service.

E14 Encoder signal error.

Turn off the system power supply, please check motor encoder connector if loose

or fall off, renew to normal then restart system.

E15 Main shaft motor overcurrent error Turn off the power, and then turn it on again.

E17 Head fall error

Please raise machine head and turn on the power again. Check if the head down

switch is damaged.

E20

Main shaft motor rotating abnormally

at startup

Turn off the power and check whether the encoder cable of the motor and the

power cable of the motor are connected to the connector.

E82 Back-tacking step motor overcurrent Turn off the power, and then turn it on again.

E84

Back-tacking step motor encoder Z

signal abnormal

Turn off the power and check whether the encoder cable of the step motor is

connected to the connector.

E85

Back-tacking step motor encoder AB

signal abnormal

Turn off the power and check whether the encoder cable of the step motor is

connected to the connector.

E86

Back-tacking step motor failed to

start

Turn off the power and check whether the encoder cable of the motor and the

power cable of the motor are connected to the connector.

E87

Back-tacking step motor locked-rotor

Please check if the step motor is locked.

Loading...

Loading...