TEXI Tronic 7 NF operation manual

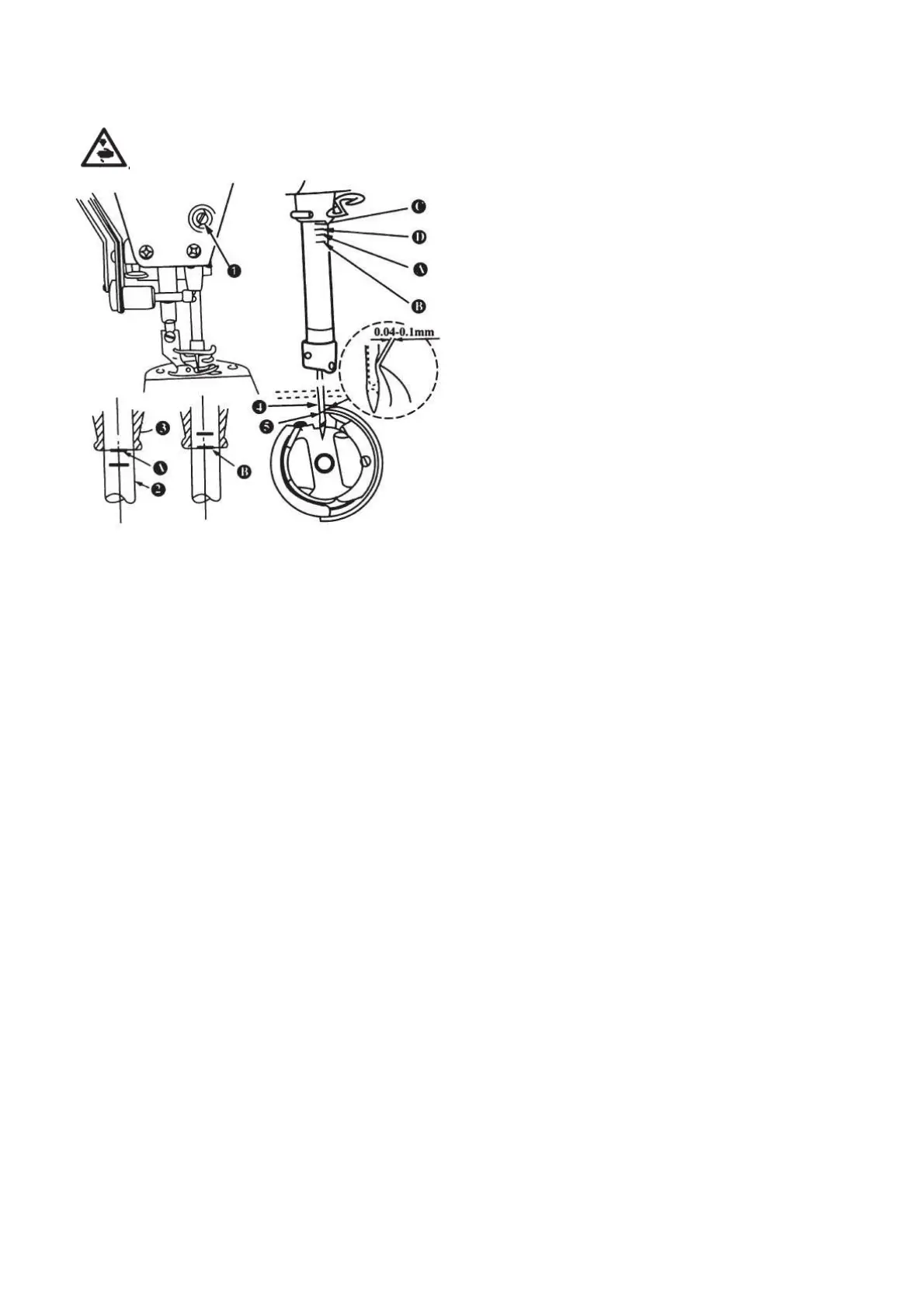

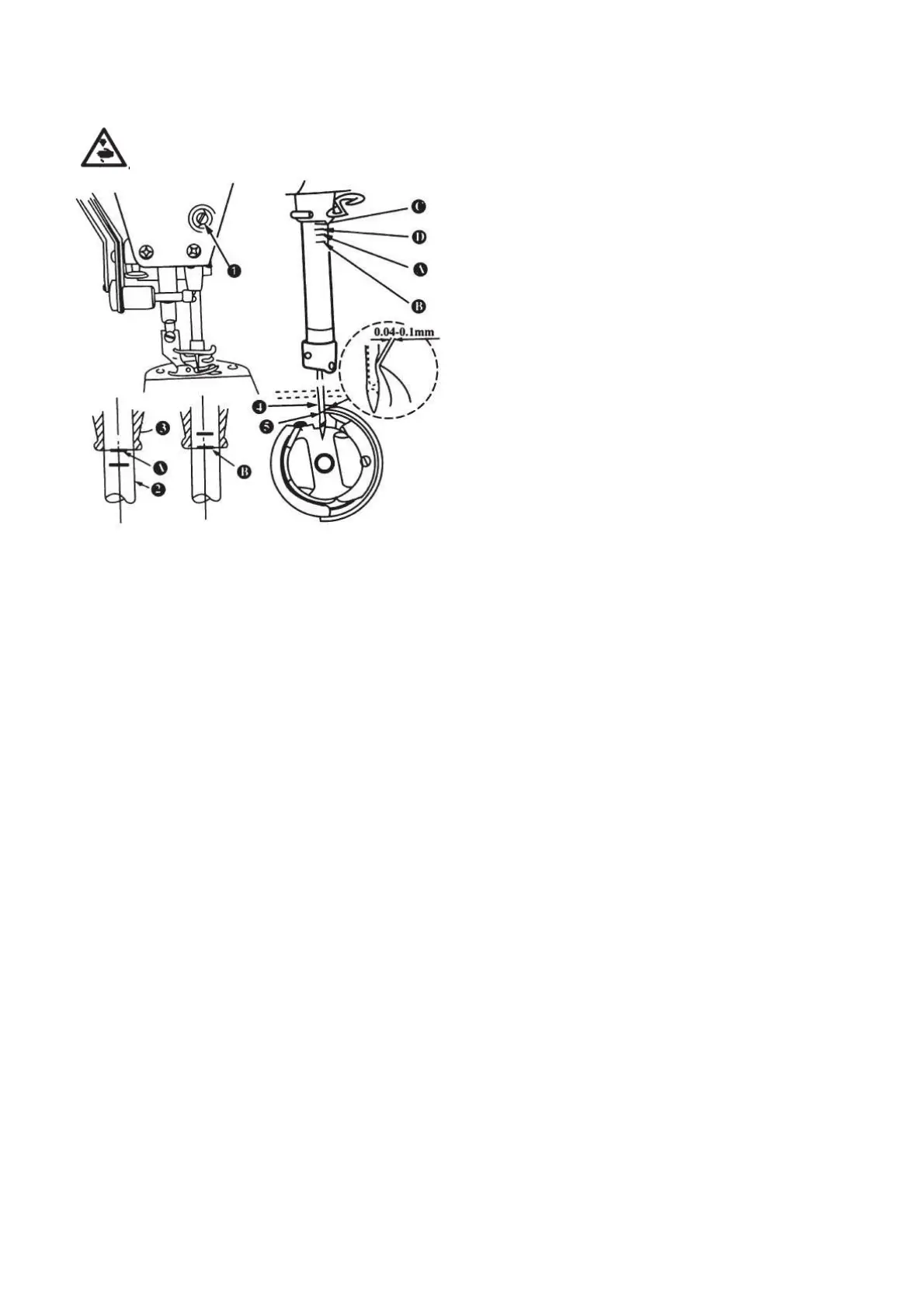

22. Needle bar and hook regulation

Warning: Turn OFF the power before starting the work as to prevent accident caused by abrupt start of the

sewing machine.

1. Turn the hand-wheel to bright the needle bar down to the

lowest point of its stroke, and loosen setscrew (1).

2. Adjusting the needle bar height:

1) While using DB needle, align marker line A with the

bottom end of needle bar lower bushing (3), then

tighten setscrew (1).

2) While using DA needle, align marker line C with the

bottom end of needle bar lower bushing (3), then

tighten setscrew (1).

3. Locate the hook position:

1) While using DB needle, loosen the three hook set

screw, turn the hand-wheel, and align marker line B

on ascending needle bar 2 with the bottom end of

needle bar lower bushing (3).

2) While using DA needle, loosen the three hook set

screw, turn the hand-wheel, and align marker line D

on ascending needle bar 2 with the bottom end of

needle bar lower bushing (3).

4. After making the adjustments mentioned in the above

steps, align hook blade point (5) with the center of

needle (4). Provide a clearance of 0.04mm to 0.10 mm

(reference value) between the needle and the hook, then

securely tighten setscrews in the hook.

Caution: If the clearance between the blade point of hook and

the needle is smaller than the specified value , the blade point

of hook will be damaged. If the clearance is larger, stitch skip-

ping will result. Use a hook of the same part No. when

replacing your hook with a new one.

14

Loading...

Loading...