9. NOW place or uncover the reflector on the blank

wall directly opposite the beam head with a clear path though

obstructions such as girders etc.

It is important that there is a clear line of vision between the reflector and any

obstruction -the beam head must see at least 200mm of clear wall around the reflec-

tor to enable successful auto alignment.

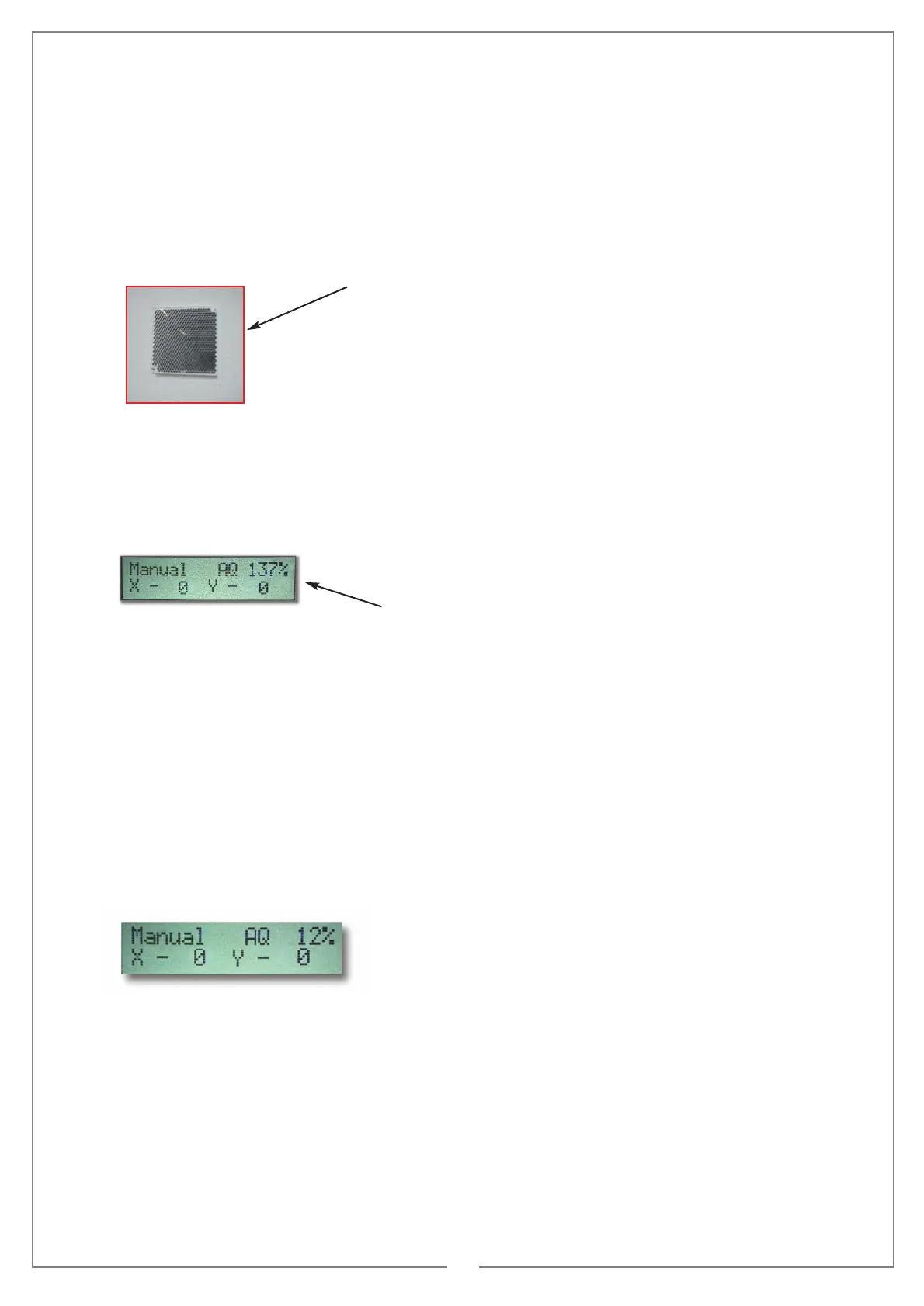

Once the reflector is in place the AQ value should jump up

meaning that the head is now seeing the

reflector.

If you have received a AQ reading of over 40% go to Auto

Alignment point 10.

you need a reading of at least 40% to proceed to Auto align-

ment. If you do not receive an AQ signal of 40% it means the

beam head is not seeing the reflector. You will need to move

the beam head until you receive an AQ reading of above 40%

ideally over 100%

If you are presented with the screen below (AQ-air quality could be any number up to 40%)

Now look at the position of the reflector in relation to the beam head. You will need to

angle the beam toward the reflector by moving the head about its X or Y axis

using the internal motors

In the example on the next page you will notice that the reflector is below the line of

fire of the beam. So in this case you would need to lower the angle of the beam (-Y)

until you receive a AQ

(Air Quality) reading above 40% sensitivity. (40 steps of the motor =

1degree of movement)

The minimum response you need to see is 40%

(below this figure the beam will not self align in the

next procedure) the higher the number the better - this

can be over 100%

clear vision around

the reflector

8

Loading...

Loading...