EX-TRAFIRE

®

75SD

Operator Manual, Revision T-57-50

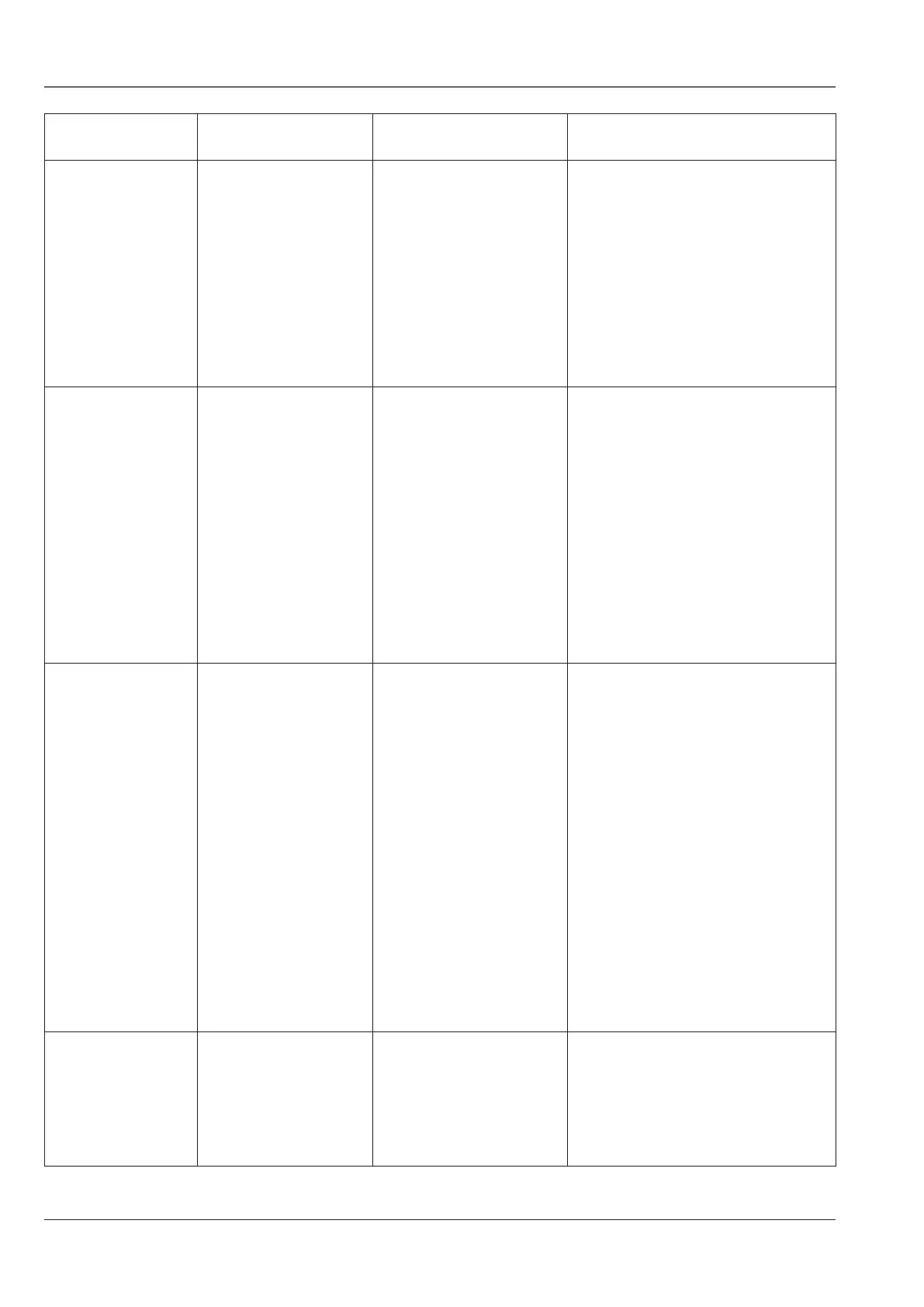

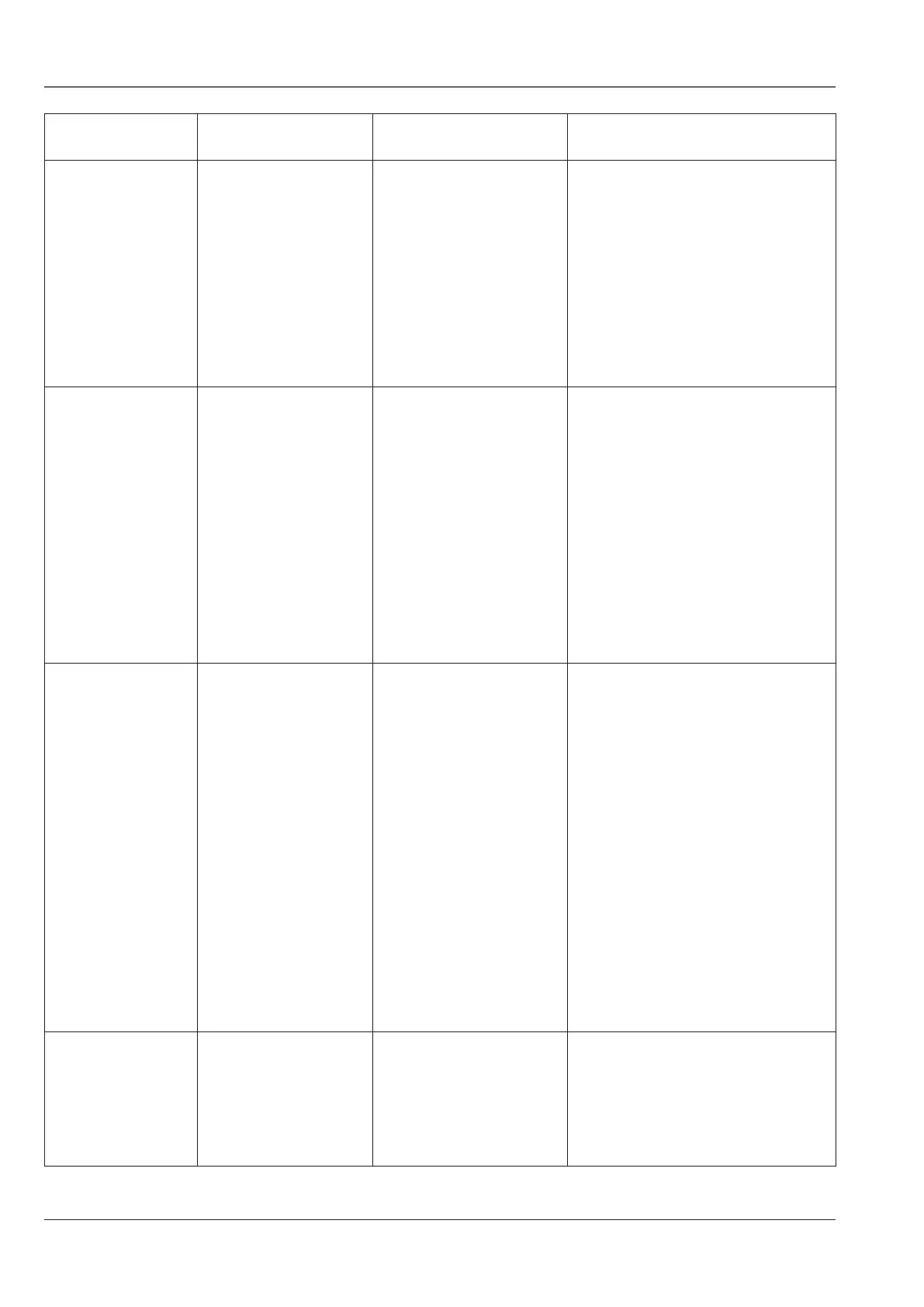

Fault This may mean Cause Solution

No arc output

but no alarm

light when

torch trigger is

depressed or

the CNC start

signal is ON�

• Torch fault� • Incorrect type of

the torch�

• Use the correct torch type

which is suitable

for the machine�

• Torch components� • Check torch components,

change parts if necessary�

• Input gas

pressure fault�

• Input gas pressure

is too high�

• Decrease input static

pressure to 7 bar/101 psi�

No transfer

between

pilot arc and

workpiece�

• Work clamp

connection fault�

• Fluctuating

connection

between the clamp

and workpiece�

• Clean the surface

of the clamp and material�

• No connection to

workpiece�

• Incorrect distance

between the torch

and workpiece�

• Maintain correct distance

between the torch and

workpiece�

• Work cable is

broken�

• Replace the work cable�

The output

is too low,

unstable or

inadequate�

• Connection fault� • Input and output

connection leads�

• Check all input and output

connection leads�

• Fluctuating

connection

between the clamp

and workpiece�

• Make sure that work lead has

a good connection to a clean

and dry area of workpiece�

• Incorrect distance

between the torch

and the workpiece�

• Maintain correct distance

between the torch and

the workpiece�

• Voltage fault� • Incorrect input

voltage�

• Use the correct input voltage,

in accordance

with specification�

The pilot arc

is difficult to

ignite and cuts

out�

• Consumables

fault�

• Check for worn

consumables�

• Change the consumable

which may be worn�

• Air pressure fault� • The air pressure is

too high�

• Adjust the air pressure

output�

Loading...

Loading...