7

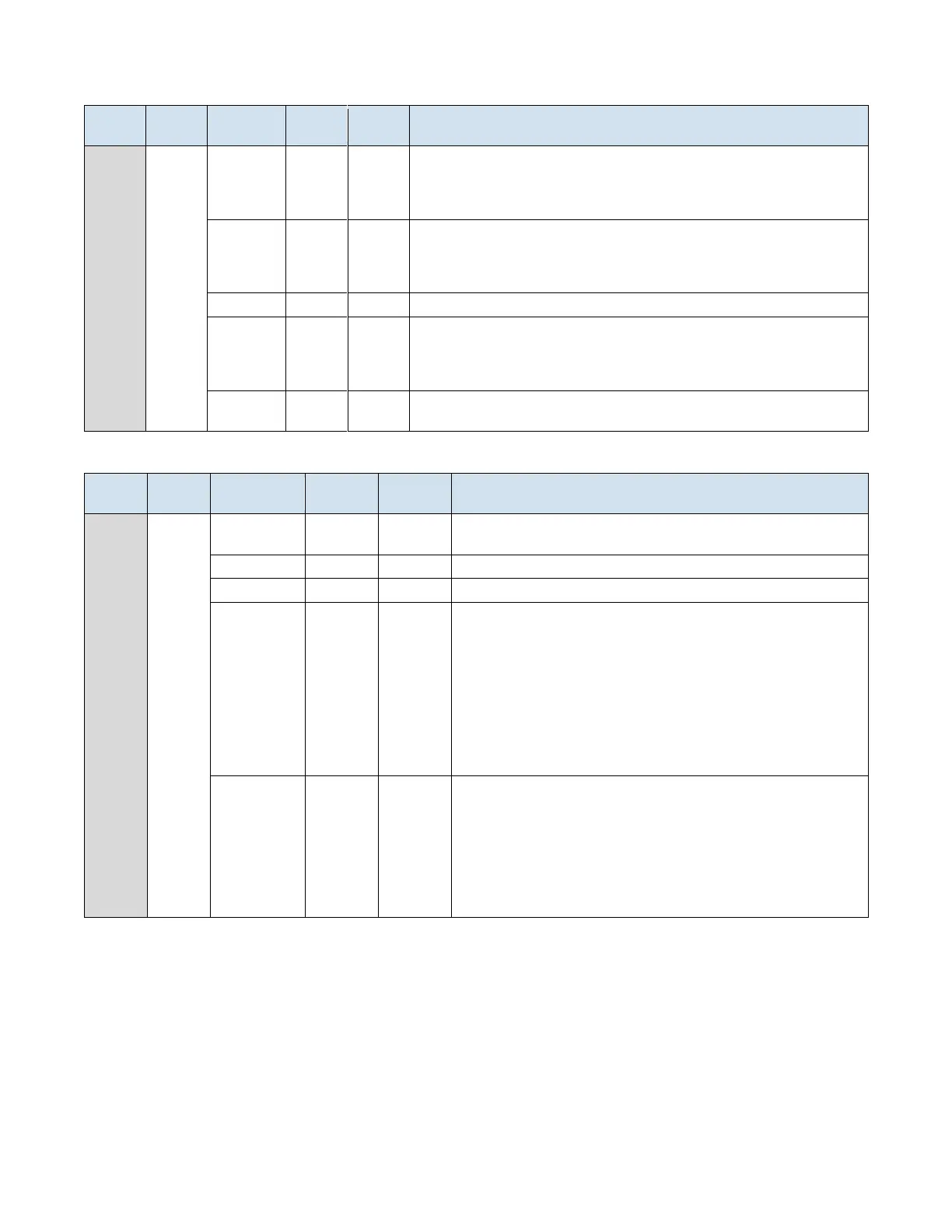

Table 1 - User Parameters (continued)

Allows the user to select how the TCU responds to a deviation condition (as

defined in screen 1/6 above). Warnings are visible on the screen, but have no

effect on machine operation. Alarms shutdown the machine and require user

intervention to reset.

After mold purge is started, this is the max time that it can run before being

automatically cancelled. Note that the user can stop mold purge at any time.*

*Only visible on menu if mold purge option is installed.

Select "Yes" if you would like to enter the diagnostics menu.

Select “Yes” if you would like to load defaults for all user parameters. If you select

“Yes”, all your customized settings will be permanently lost and default

parameters will be used instead. The controller will reboot after implementing

default settings.

Used to enter a password for a factory configuration menu.

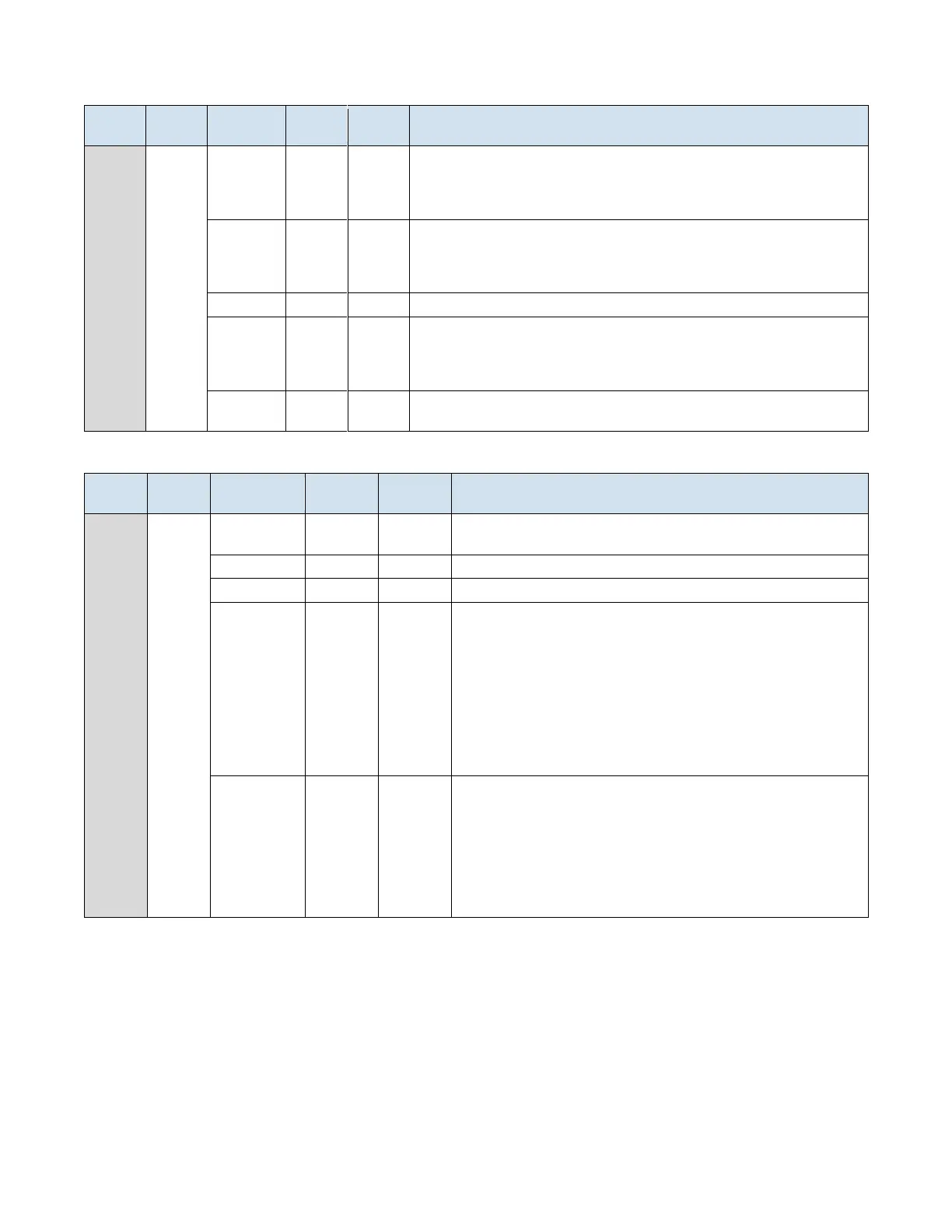

Table 2 - Factory Parameters

Allows the factory to set whether or not mold purge is installed as an

option.

Maximum permitted machine setpoint.

Minimum permitted machine setpoint.

Describes the effectiveness of cooling vs effectiveness of heating. Having

the correct value here enhances the performance for the PID algorithm.

For example, if the TCU’s cooling BTU removal happens at twice the rate of

the TCU’s heating BTU addition, this number should be set to 2.0. Systems

with small heaters and plentiful, cold cooling water may want a value of

1.5. Alternatively, warm cooling water or a very powerful heater would

work best with a value of 0.75. A value of 1.0 means there is no distinction

between heating/ cooling and the PID works in a very traditional manner.

Conduct any experimentation to set this value at lower process

temperatures.

This parameter helps the TCU achieve setpoint quickly and without

overshoot across the entire temperature range of operation. This factor

multiples the “Cool-Heat Rto” set in the parameter above at high

temperatures. For example, if “Dynamic Mult” is set to 1.75, a Cool-Heat

Rto of 1.25 will actually become 2.19 (1.25 x 1.75 = 2.19) when the TCU is

running at a process temperature of 250°F. Set to zero to disable all

dynamic effects, in which case parameter “Cool-Heat Rto” will be solely

responsible and at a fixed value across the entire temperature range.

Loading...

Loading...