Disassembly

and

Beassembly

(Rev.

7. 12l01)

5.

J.

Remov€ the Keyway Tool and check the fil of the new

kcy. Il should lit into the keyway with a light pEss fit

requiring only

a

nrinimun

of

light

tapping. lf lhe key

doe,

nor fir

tr"perly.

remn\e rhe coupling rnd inspect

the teyways and key tbr burs or other

problems.

Rccheck lhe lit as shown above.

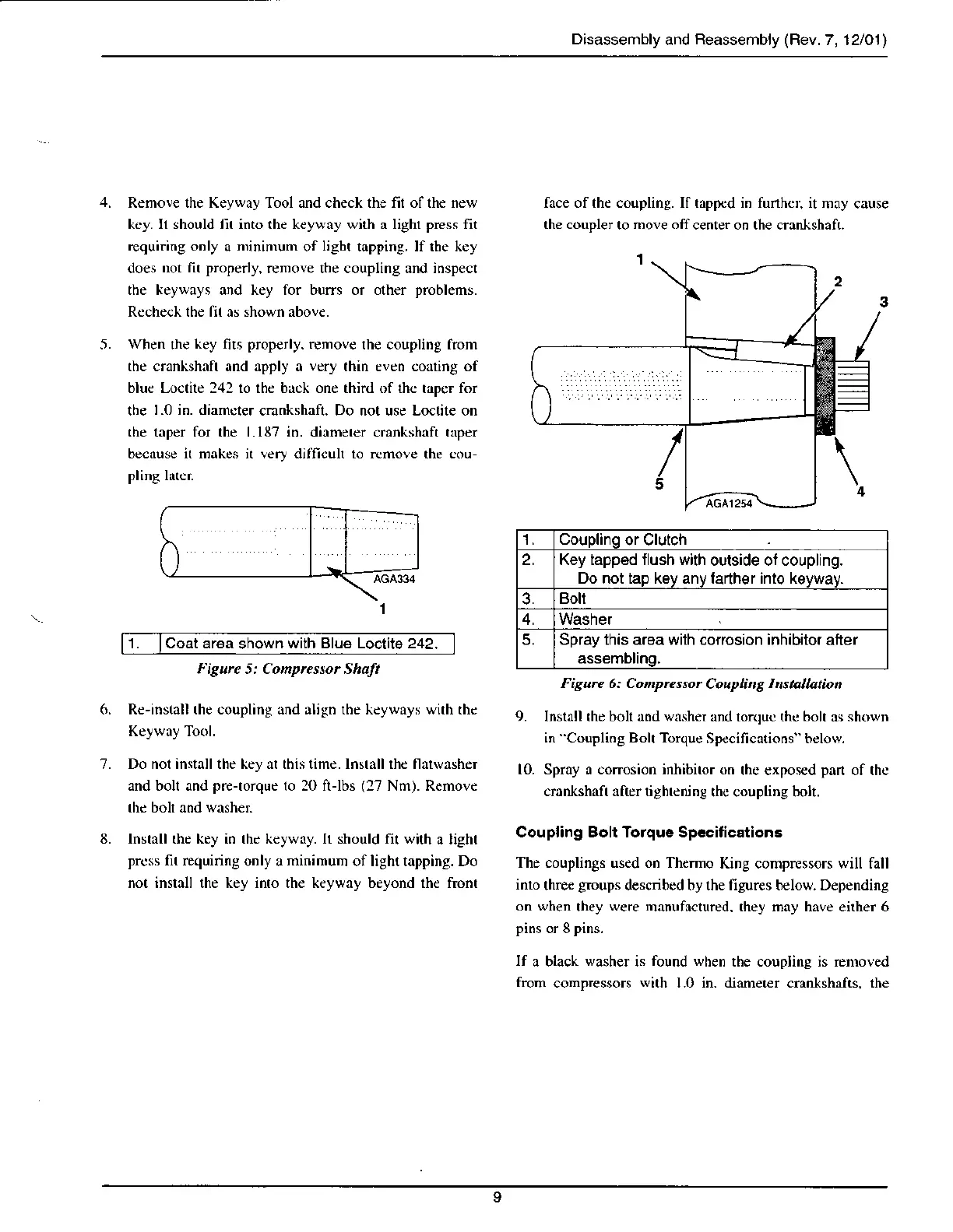

when

the

key

fits

prop€rly. remove

lhe coupling from

the crankshnft and apply a

very

lhin even corting of

bluc Lo€lite 242 to the brck one third of the tapcr for

the

I.0 in. diamcter

cmnkshaft. Do not use Lo€tile on

the taper fbr the Ll87 in. diamerer crankshnft trper

becruse it makes it lery dilficuh 10 remole thc cou-

plinS latcr

1.

lCoat

area

shown

with Blu€ Loctita 242.

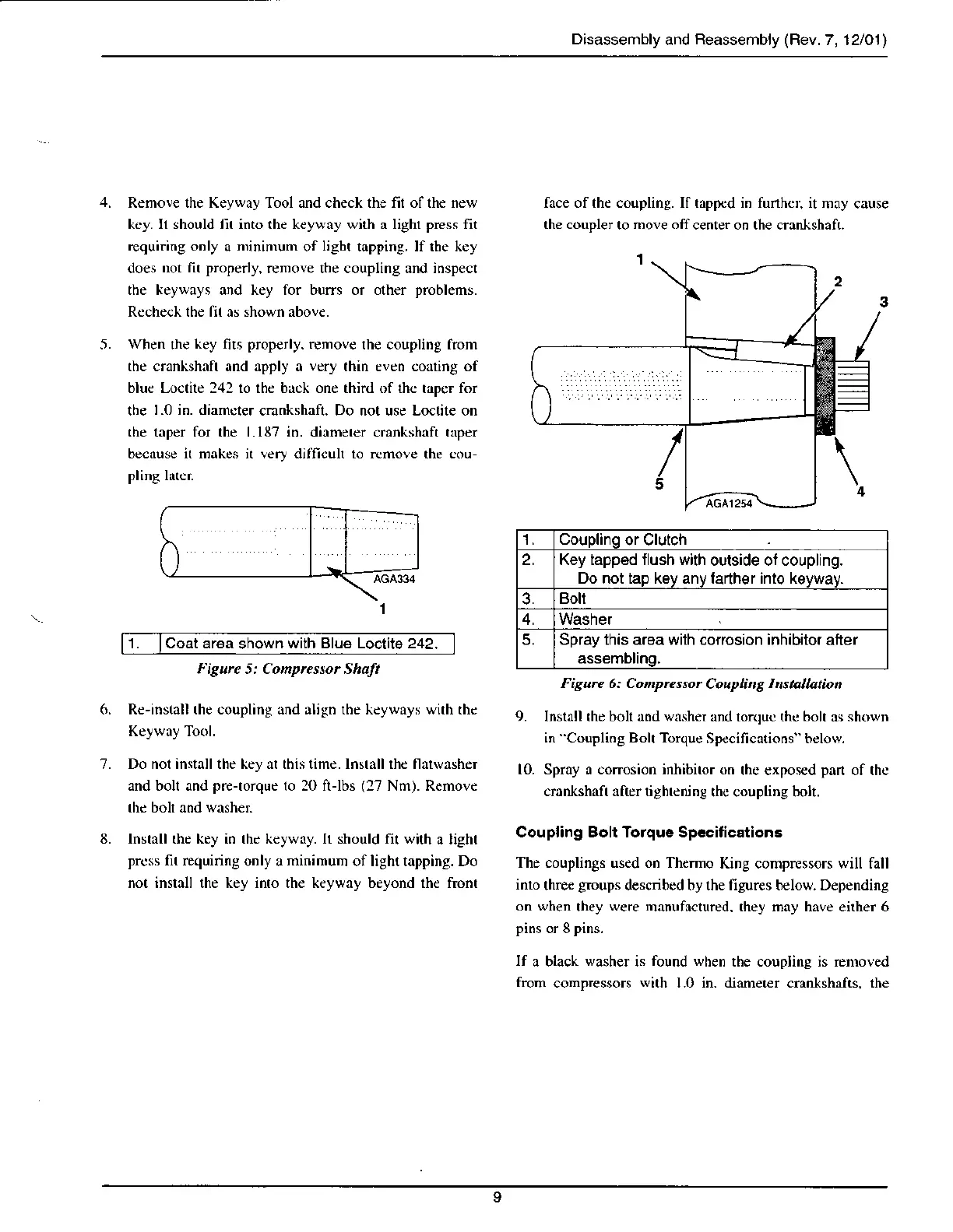

face of lhe coupling. If tapFd in funhcr, it

nay cause

the coupler

to

nove off

center on the crar ishaft.

1. Couplinq

or Clutch

2. Key tapped flush with

outside ot coupling.

Do not tap key any larth€r into keyway.

3.

Boll

4.

5. Spray this area with corrosion inhibitor

after

assembling,

l isutc s: Conpressor Shalt

Rc-ins(all the coupling and rlign the keyways with thc

Keyway Tool.

Do nor installthe key fl this time. lnsrall rhe fl w,Nher

and bolr and

pre-rorque

ro 20 ft-lbs

(27

Nrn). Renove

lnstrll the key in rhc keywry. Ir should fil with

a light

prcss fit requiring

only a

ninimum

oflight tapping. Do

not inslall the key inro the keyway beyond the fronr

Fisure 6: Conprcssor

Coupling

Instauation

9. Instrll the bolt nnd wnshe.

and lorquc thc

bolt

as

shown

in

Coupling

Bolt Torque

Sp€cifications" below.

10. Spray a conosion inhibitor on

the €xposed

pan

of thc

.mnl,shxfr :rfrrr ri8hrcnjng rh(

(oupling

hoh.

Coupling Boll Toiquc Spccitications

The couplings used on Themo

King compressors will fall

into

three

groups

described by the figures below. Depending

on wh€n

they

were

manufactured. they may have either 6

pins

or 8

pins.

If

a black

washer

is

found when

the coupling is removed

frorn

compressors

with

1.0 in. diameter crankshafts. the

Loading...

Loading...