Disassembly and Reassembly

(Rev.

7. 12101)

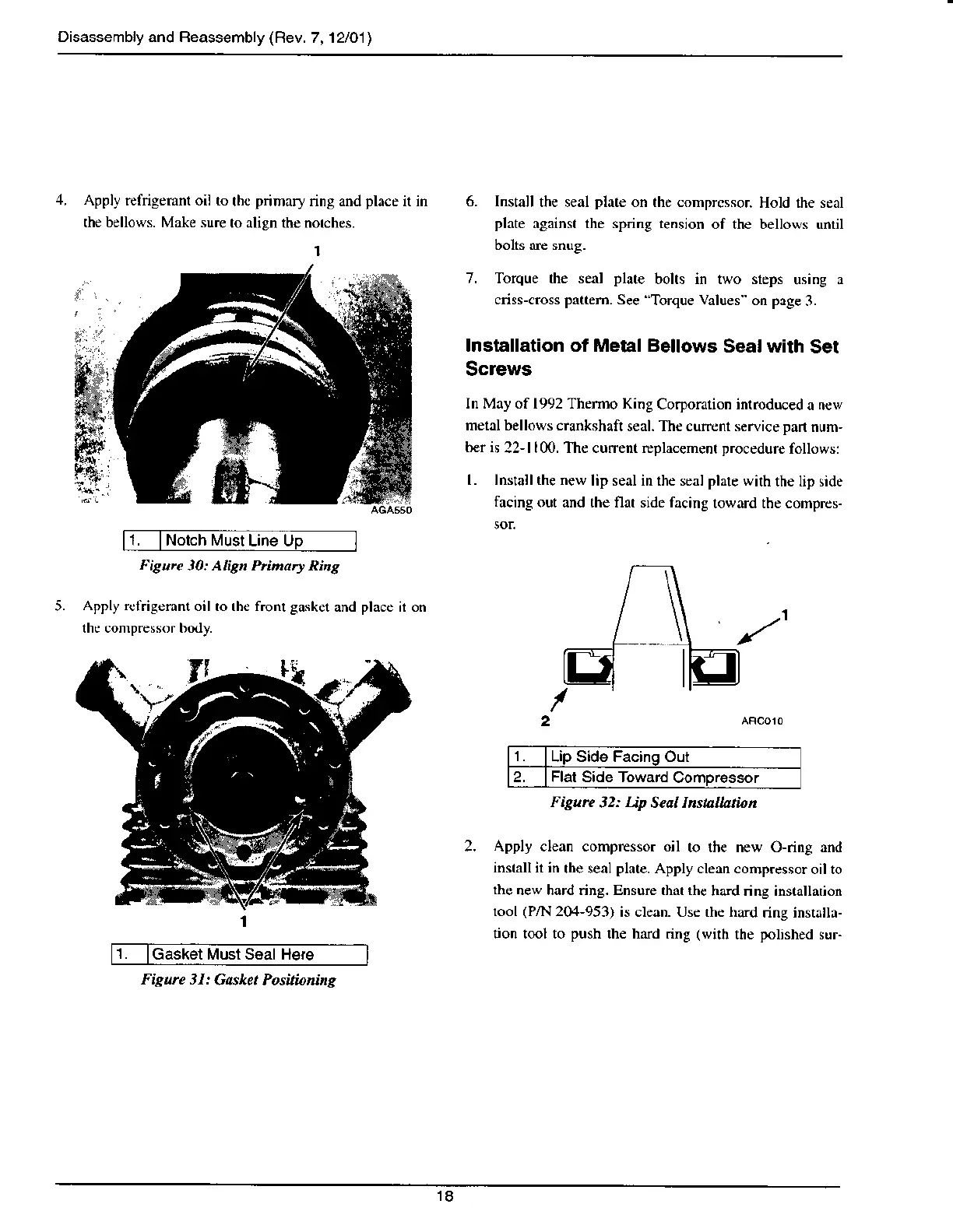

Apply relrigerant oii to

tbc

primary

ring and

place

it in

the bellows. Make sure

to align the nolches.

I

6. Install

the seal

plate

on lhe comprcssor.

Hold the seal

plate

againsl the spring tension

of the bellows undl

7. Torque lhe seal

plate

bolts in two sleps

using a

crisycross

pfltem.

see

Torque

Vrlues

on prge

L

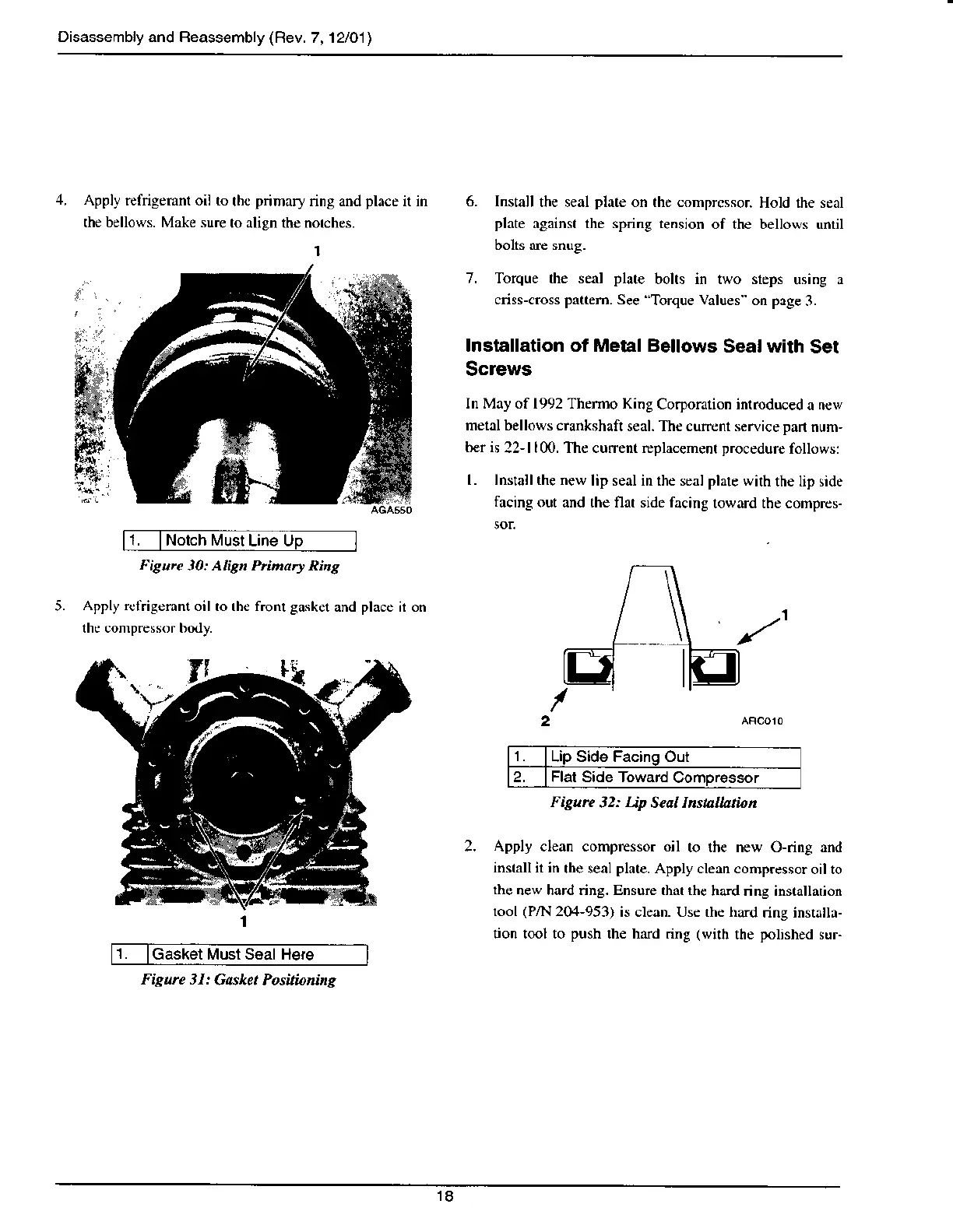

Apply rclrigerant

oil ro rhe front gasket

and

place

it

lhe compressor body.

1.

lNorch

Must

Line Up

l'isutc

30: AlE himary Rins

1.

lGasket

Must S6al H€re

Figure 3I:

Caslet Positianing

Installation of Metal Bellows

Seal with

Set

Screws

In May of 1992 Thermo King

Corporalion int.oduc€d

a new

metal bellows crankshafi

seal. The current service pan

num,

ber is

22-l 100. The curren( replacement procedure

follows:

l. Install the new

lip seal in the scal plare with

the lip side

facing

out and the flfl side facing

loward the comprcs-

2.

Lip Side Facing Out

2.

Flat

Side Toward

Comoressor

Figu?e

32:

Lip

Seal InstaUatian

Apply clean compresso. oil

to ihe new O-ring rnd

inshll it in

the $eal

plate.

Apply clean conpressoroil

ro

the

new hard ring. Ensure that thc

hard ring installarion

tool

(P,N

204,953)

is clean. Use the hard

ring installa-

tron tool to

push

the hard ring

(wilh

the

polished

sur-

18

Loading...

Loading...