Disassembly and Reassembly

(Rev.

7. 12l01)

fa€e toward thc instrllrtion t@l)

plarc. Do not pinch

the O-ring.

fully inb

thc seal CAUTION: Do NOT touch

or danage the

potkhed

seat

face

su.Ioces.

l. Bnck out the sel screws from the

new serl and apply n

smrll anoum of removable

thread locking conpound

(Loctile

242

3l blue P/N 103-.{}0) to thc sct sqcw

CAUTION: Kecp th" orung? protectiee

cap in

position

un.il

lnal

asscnbry.

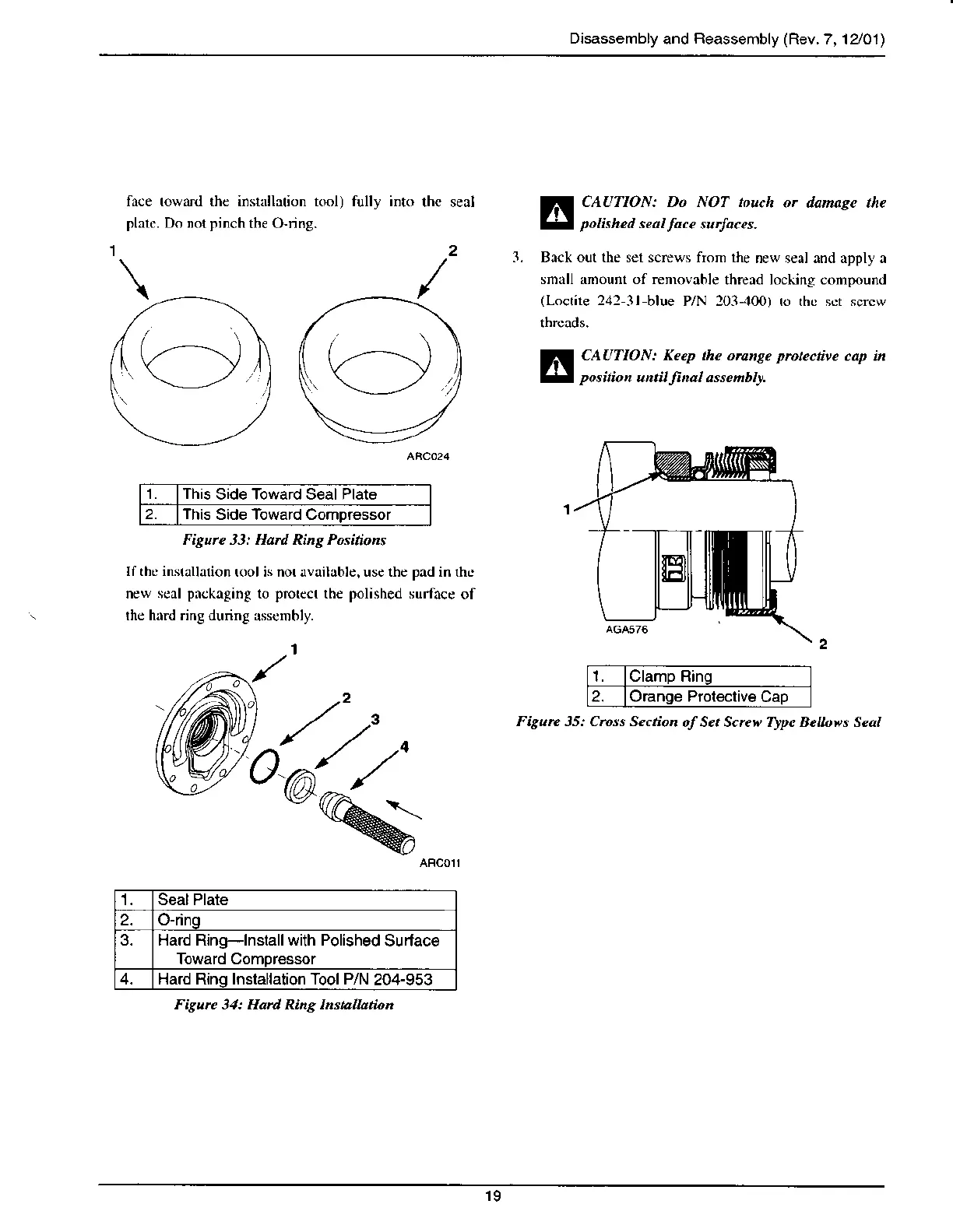

1 Th

s Side Toward Seal Plate

2. tn

s Side Toward Comoressor

Figure 33: Ha.d Rins Positions

If thc instauation

toolis nor.rvail$le, use the

pad

in fte

new scal

pnckaging

to

protect

the

polished

surface

of

rhc hrrd ring dunng

$scmbly.

,tt

'ok'

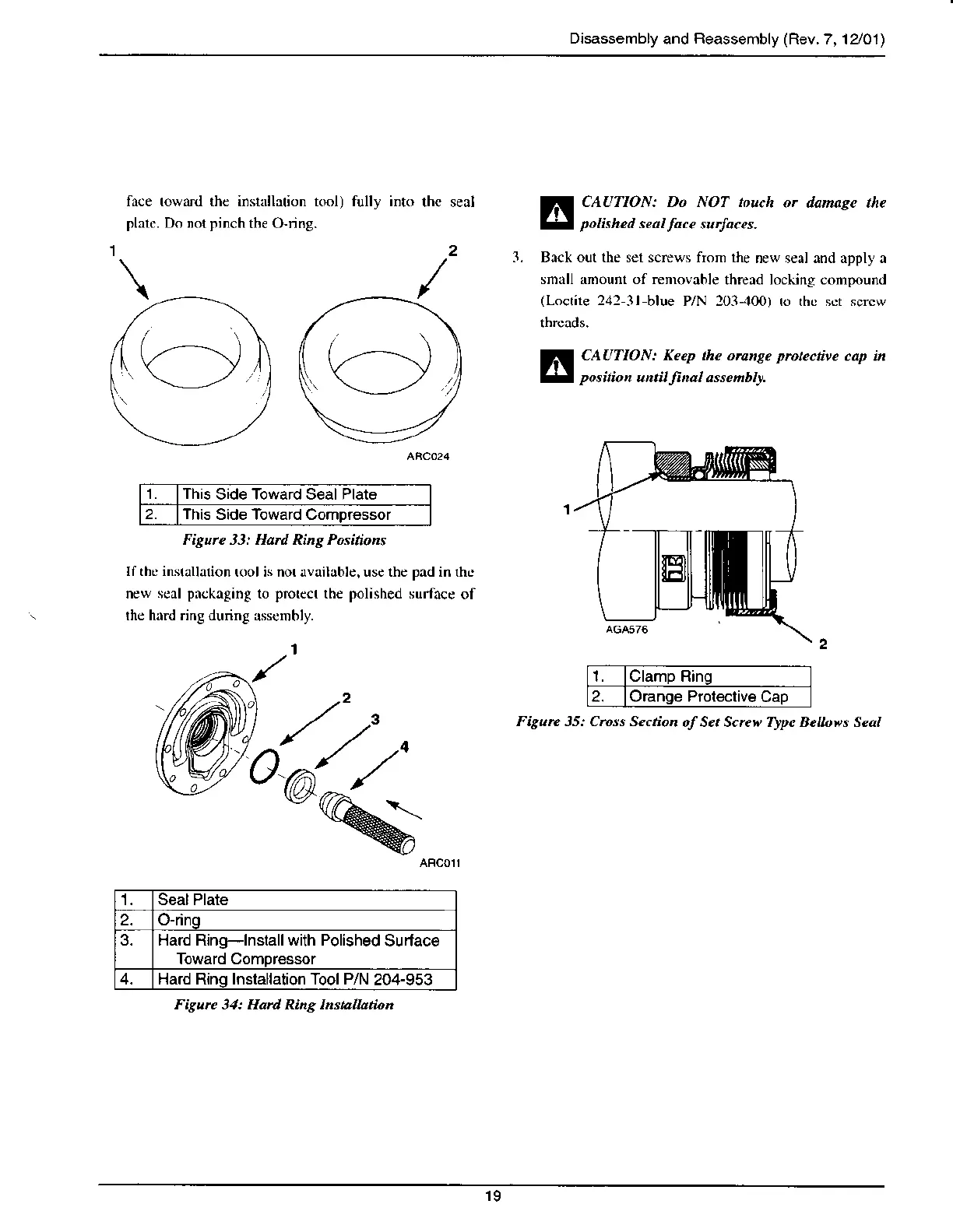

Seal Plate

2. O-dng

3. Hard Ring-lnstall with Polished

Surtace

Toward Comoressor

4. Hard Rinq Installation Tool P/N

204-953

Figure 31: Hard Ring Instalhtion

l Clamp Ring

2. Orange Proleclive

Cap

Figun 35: Cross Section

ofSe. Scre|'Type Beuoes Seal

19

Loading...

Loading...