Disassembly and Beassembly

(Rev.

7, 12l01)

'7.

8.

Renrovc the sealinstillation tool. l.

Removc lhe orange

proteclive

cap. Clean the

hard nng

and the primary nng

(bronze

ring) with the rlcohol

wipes

fbund

in package labelcd l . Thcn clean thc

polished

maling

surfaces

of

both rings with the lint frcc

dry

wipes

liom

package

number

":

.

Apply

clean

comprcssor oil ro the

polixh€d

surfaces of $e seal. the

Iip scal. and thc sc.

plnte g.rsket

lrom

packnge

number

'':]'

bcforc nsscmbling.

CAUTION:

Oil applied to the seal

laces

nust

be absolutelr clean,

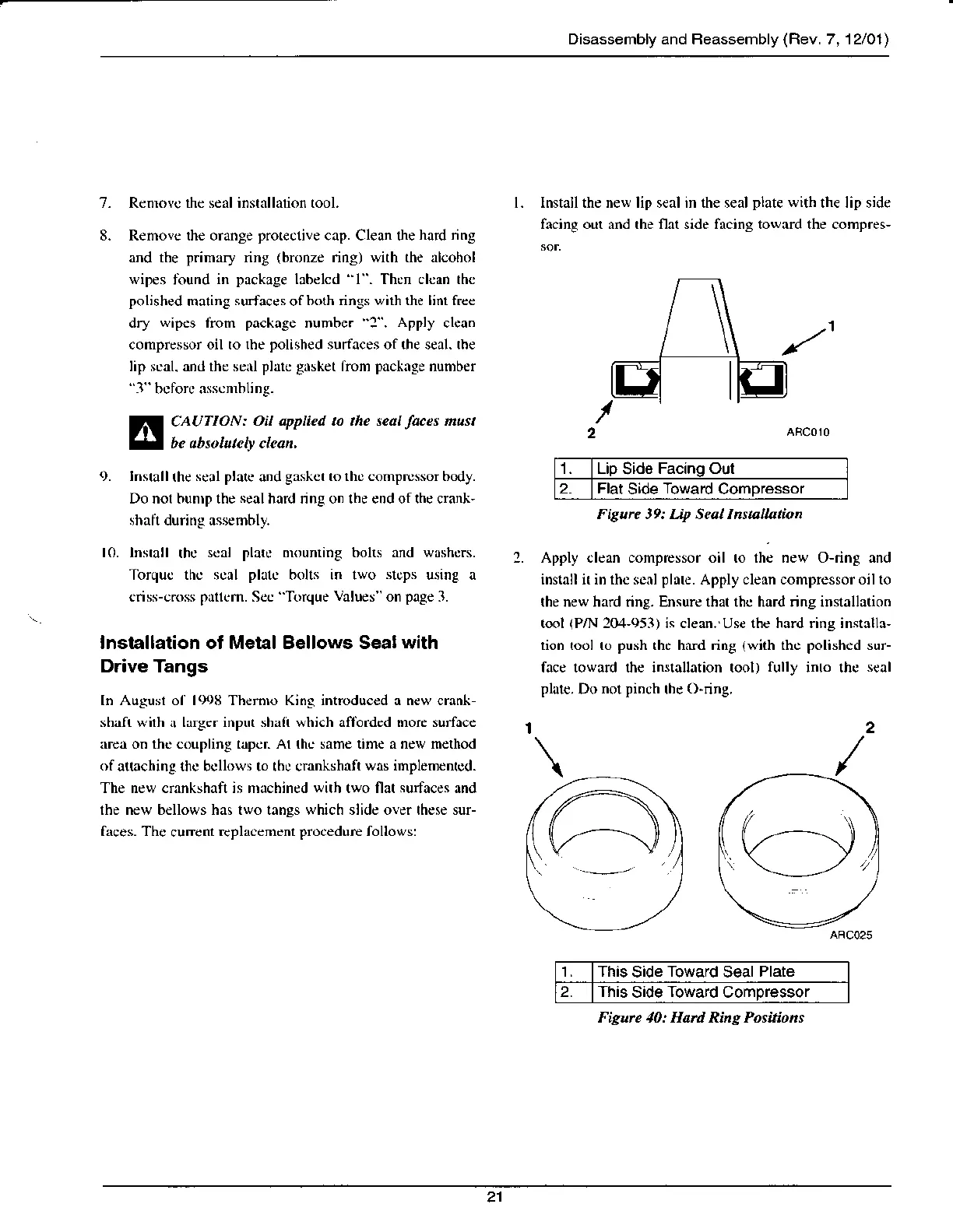

lnstall the new lip seal in the seal

plate with

the lip side

facing our and rhe flat side frcing toward the compren

1. Lio

Side

Facino Out

2. Flat

Side

Toward

Compressor

Figun 39: Up Seal Instalation

9. Install

the

scal plalc

and

gaskct to tht! comprussor body.

Do nol bunrp the

seal

hard ring on lhe end of lhe crank'

shafi during assembly.

f0. lnstall

thc

scai plalc n$unling bolls rnd wdshc6.

2.

Tor.tuc th,:

\(fl1 plrl( h,'ll' in rsu

n(p' using a

crisrcrcss

prtlcm.

Sec Torque

Values

on

page

3.

lnstallation ot Metal Bellows Seal

vvith

Drive Tangs

In Augusi ol 1998 ThemD King introduced a new cmnk-

shdt wirh

r

lrrgcr input shrli which afibrded more surfice

arc.r on th. coupling tdpen Al thc same time a new merhod

ofatiaching

thc bcllows to rhc crankshaft

was implemcnrcd.

The new crankshafl is machincd

with

two flat

surfaces

and

lhe new bellows has two langs which slide over these sur-

faces. Thc

curcnl

rcplacencnl

procedure

follows:

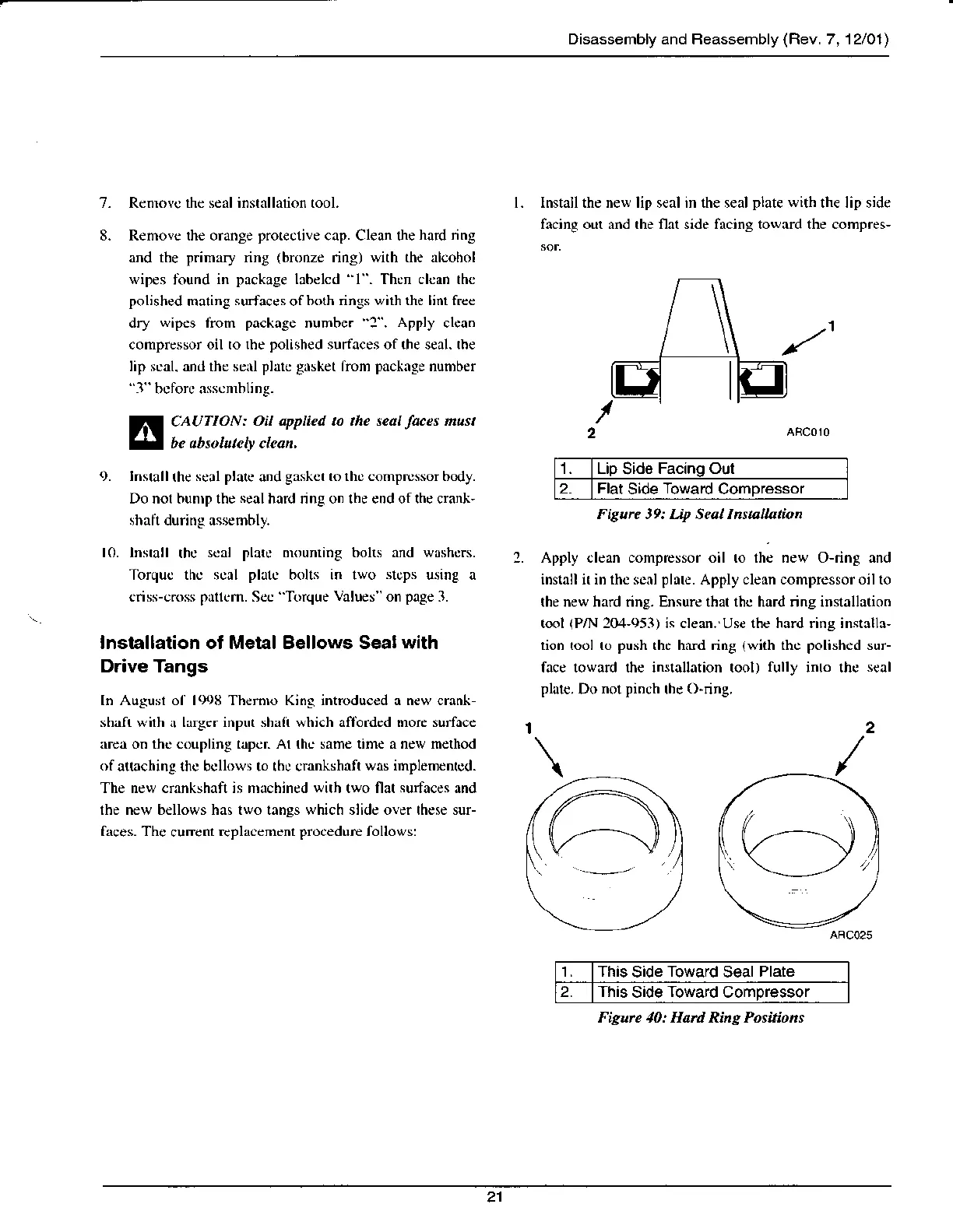

Apply €lean compressor oil ro lhc new O-ring and

inshll ir in thc scnl

plare.

Apply clern compressor o,l to

the new hard ring. Ensure that thc hard ring installation

tool

(P

{:0,1-953)

is clean. Us€ thc hard ring installa'

tion tool to

push

the hrrd ring

(with

the

polished

sur-

face loward the installation tool)

fully

into thc

seal

plat€.

Do

nol pinch

thc

O"ring.

1 This

Side

Toward

Seal

Plate

2. This

Side

Toward

Compressor

Figure 10: Hard rjng Positions

21

Loading...

Loading...