11 -4

MODEL (S): 1286, 1287

Test Voltage: 1

15, 230 Frequency: 60, 50 Hz FLA:

Magnehelic Gauge Reading

Damper Position: Position from "Open"

(Test points on speed control board - Terminal

"N" neutral and Terminal "M" motor.)

True RMS Voltage To motor:

NOTE: Use True RMS volt meter.

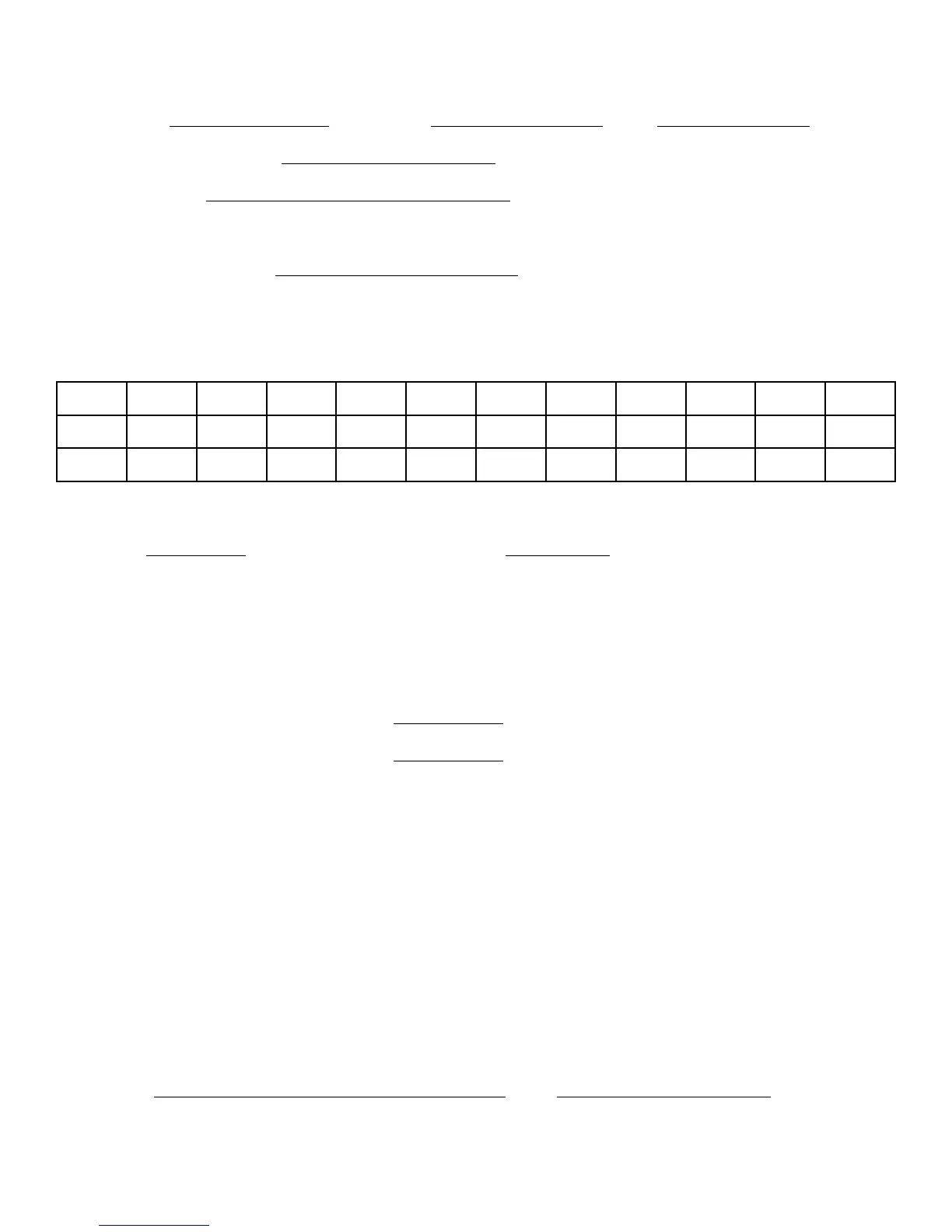

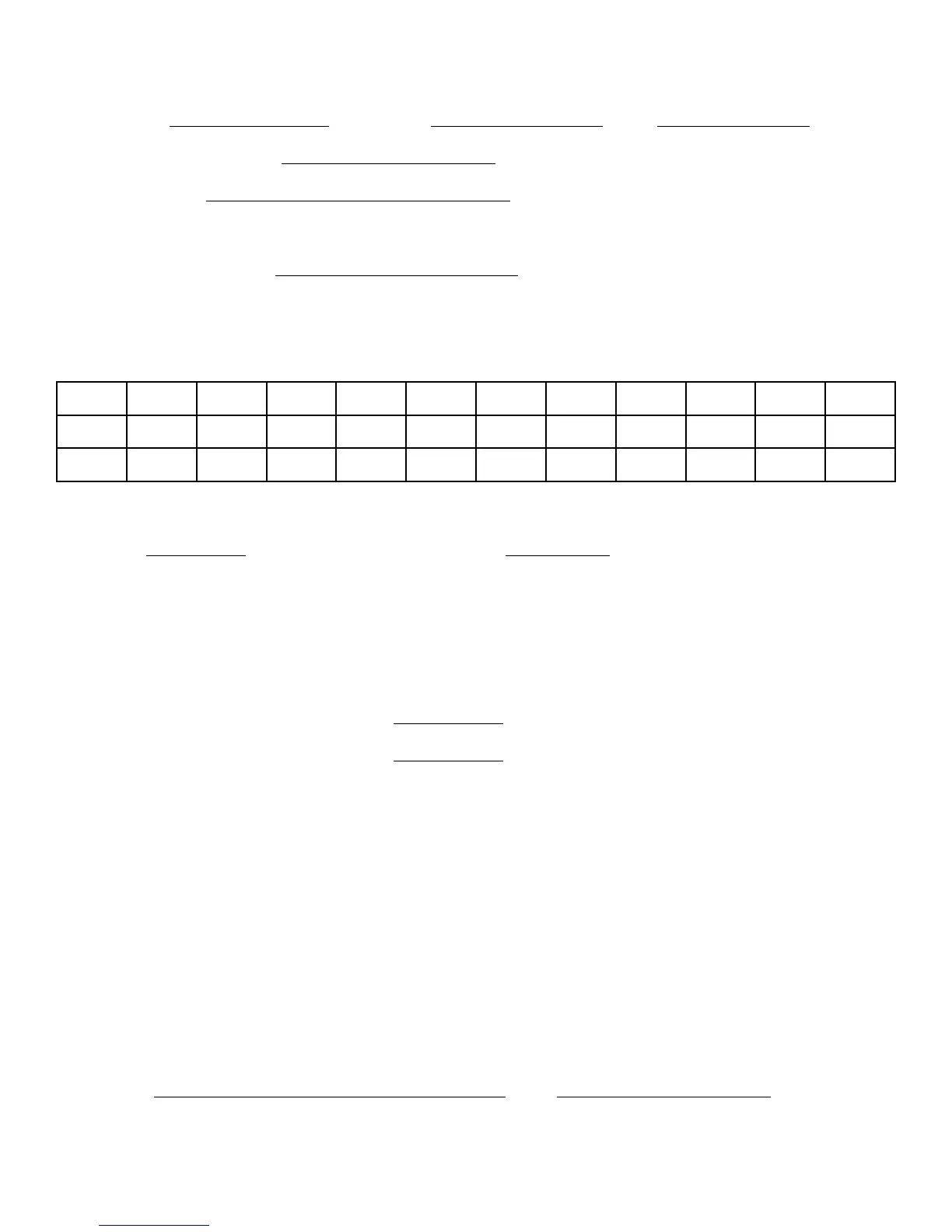

Velocity Profile: 6.0 Inches from side with successive points 5.55 inches apart.

6.0 Inches from rear wall with successive points 5.50 inches apart in a plane four inches above the

window edge.

Rear Wall

Total Sum

÷ 36 = average down flow velocity LFPM.

Acceptable down flow range 70-80 in linear feet per minute.

Work Access Opening Airflow

A. Direct Reading Instrument Method

Inflow volume (~ exhaust volume)

cu. ft.

÷ Front access opening 5.052 sq. ft.

= Calculated face velocity

LFPM

Acceptable range for face velocity 105-115 LFPM

B. Thermal anemometer Method

17 Readings

1.5” below bottom edge of window (3” high constricted opening), 6.00” from inside edges of the

access opening (sidewalls), with successive pts. 3.80” side to side. NOTE: Gaps between window

and front face of side wall must be sealed during testing. Thermal anemometer probe must be

positioned at a 30° angle from front nosing. Multiply K factor of 1.08 by average velocity reading.

3” access opening 1.516 sq. ft.

10” access opening 5.052 sq. ft.

Acceptable range for face velocity 105-115 LFPM

TESTED BY:

DATE:

Loading...

Loading...