Section 3 - Installation

3.1 Location

Locate the cabinet on a firm, level surface in an area of

minimum temperature changes. The cabinet should be placed

away from disruptive air currents caused by excessive person-

nel traffic, air-conditioning or heating ductwork, or laboratory

windows and doors. Proper cabinet location is important, as

drafts disrupt critical airflow characteristics and allow room

contaminants to enter or escape the cabinet work area.

Where space permits, fourteen inches should be allowed on

each side of the cabinet for maintenance. A twelve-inch height

should be available from the top of the cabinet to the ceiling.

Place a bubble-type level on the work surface. Adjust the

leveling feet until the cabinet is level and the most comfortable

working height is achieved. Ensure that all four leveling feet

are fully flush against the floor to prevent vibration.

Model 1284/1285 weighs 735 lbs. Model 1286/

1287 weighs 940 lbs. Have sufficient personnel to

lift it.

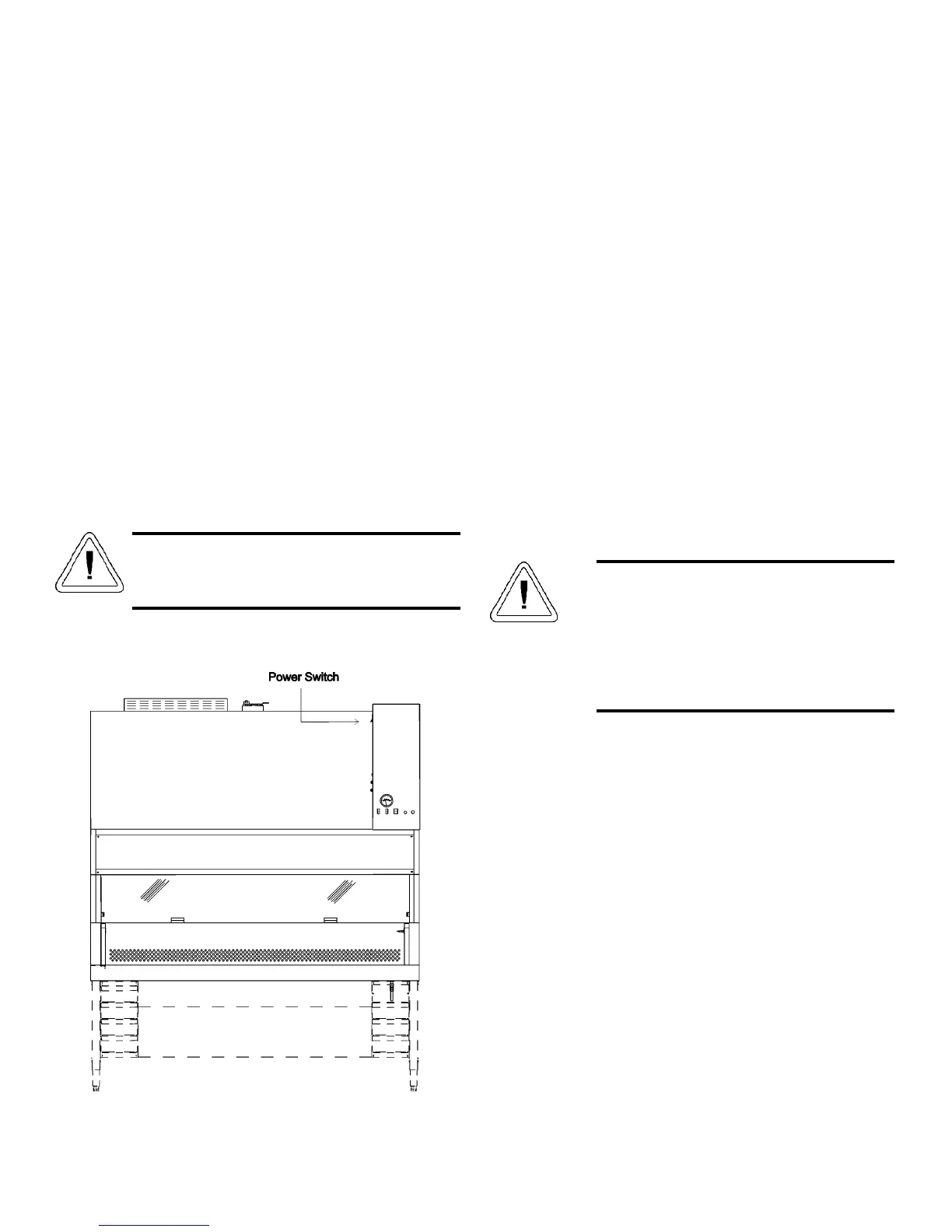

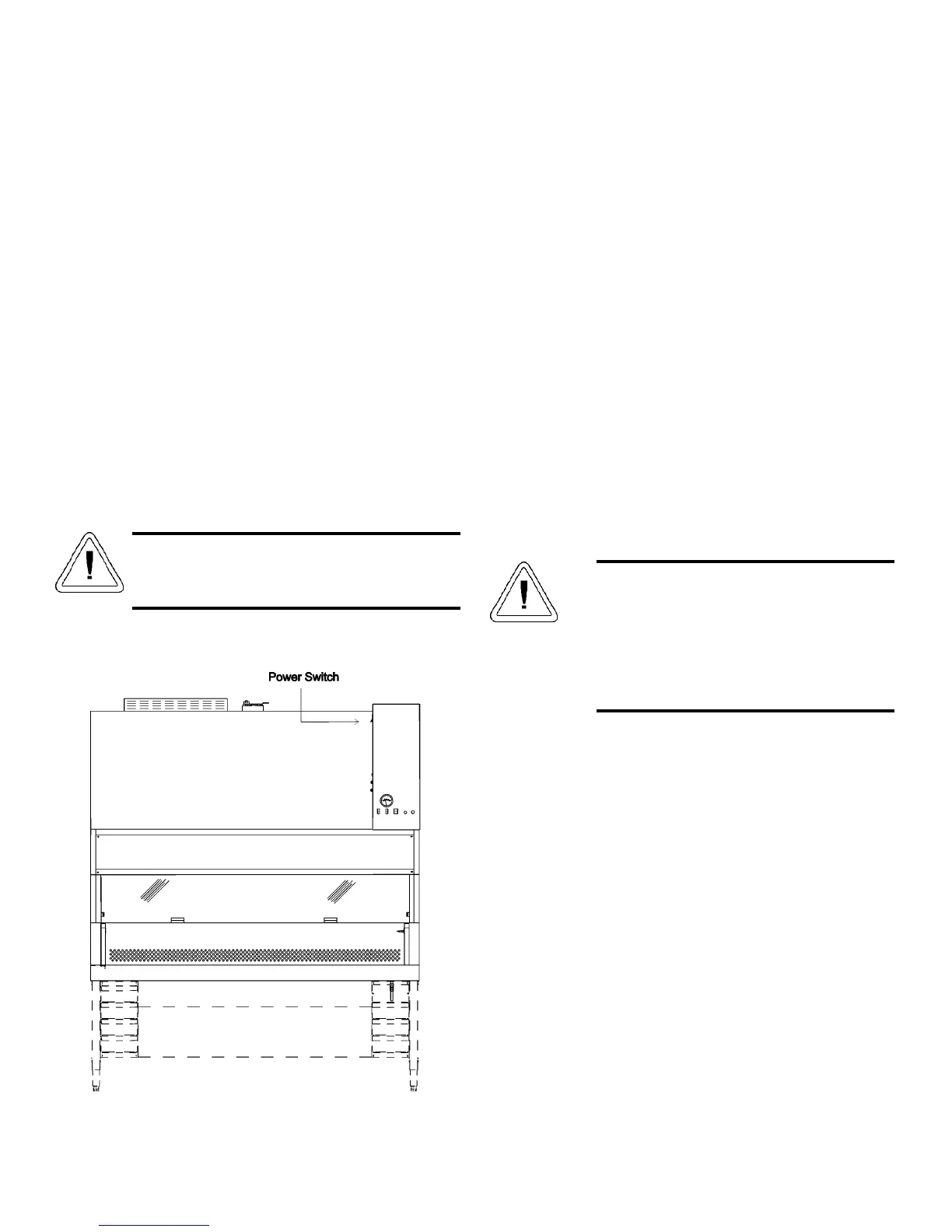

3.2 Power Connection

The power switch is located on the left side of the control

panel (Figure 3 - 1). The power switch is also a circuit breaker

that protects the unit. The electrical wall outlet leading to the

cabinet should be accessible for electrical testing.

This cabinet is equipped with one power cord supplying

power to the blower, lights and receptacles. The cord should be

plugged into a grounded, dedicated circuit. Refer to Section 11

- Specifications or to the serial plate on the front of the unit for

electrical specifications. With the power switch turned off, plug

the line cord into the wall outlet.

3.3 Plumbing Connection

Models 1284 and 1285 have one standard service valve

located on the right side of the work station. Models 1286 and

1287 have two standard service valves located on the right and

left side of the work station. All service valves are piped within

the cabinet. External connection is a 3/8” FPT coupling.

Identification index buttons are supplied. Each cabinet can

accommodate a total four service valves.

Explosive/flammable substances should

never be used in the cabinet, unless approved

and monitored by a biological safety officer

or other qualified individual. However, if

flammable gas is used, emergency shut-off

valves must be located in an accessible area

external to the cabinet.

a. Universal Plumbing Option

The Universal Plumbing option is factory installed.

External connection (1/4” NPT) to the unit is available on the

top and the underside of the cabinet, as well as the standard

side connection. See Figure 3-2.

Class II, A2 Biological Safety Cabinets_______________________________________________________________Installation

3 - 1

Figure 3 - 1

Loading...

Loading...