3-8

CHAIN TIGHTENER 3.4

Chain Tightener Removal

1 Remove any attachment, raise the boom arms and

engage the boom support pins. Shut off the engine.

2 Block the loader securely with all four wheels clear

of the ground.

3 Remove the wheels from the side of the loader to be

repaired.

4 Drain the lubricating oil from the final drive housing.

Refer to Section 3.2 page 3-3.

5 Remove the final drive inspection cover located

between the 2 axles.

6 Loosen the chain tightener and adjuster and discon-

nect the chain. Refer to Section 3.3 page 3-5.

7 Rotate the front axle and pull the excess chain rear-

ward through the chain tightener sprocket. Leave the

chain in the housing.

8 Remove the 3 chain tightener nuts. You may require

some help to hold the tightener assembly as you release

the nuts. The tightener is now free to be removed.

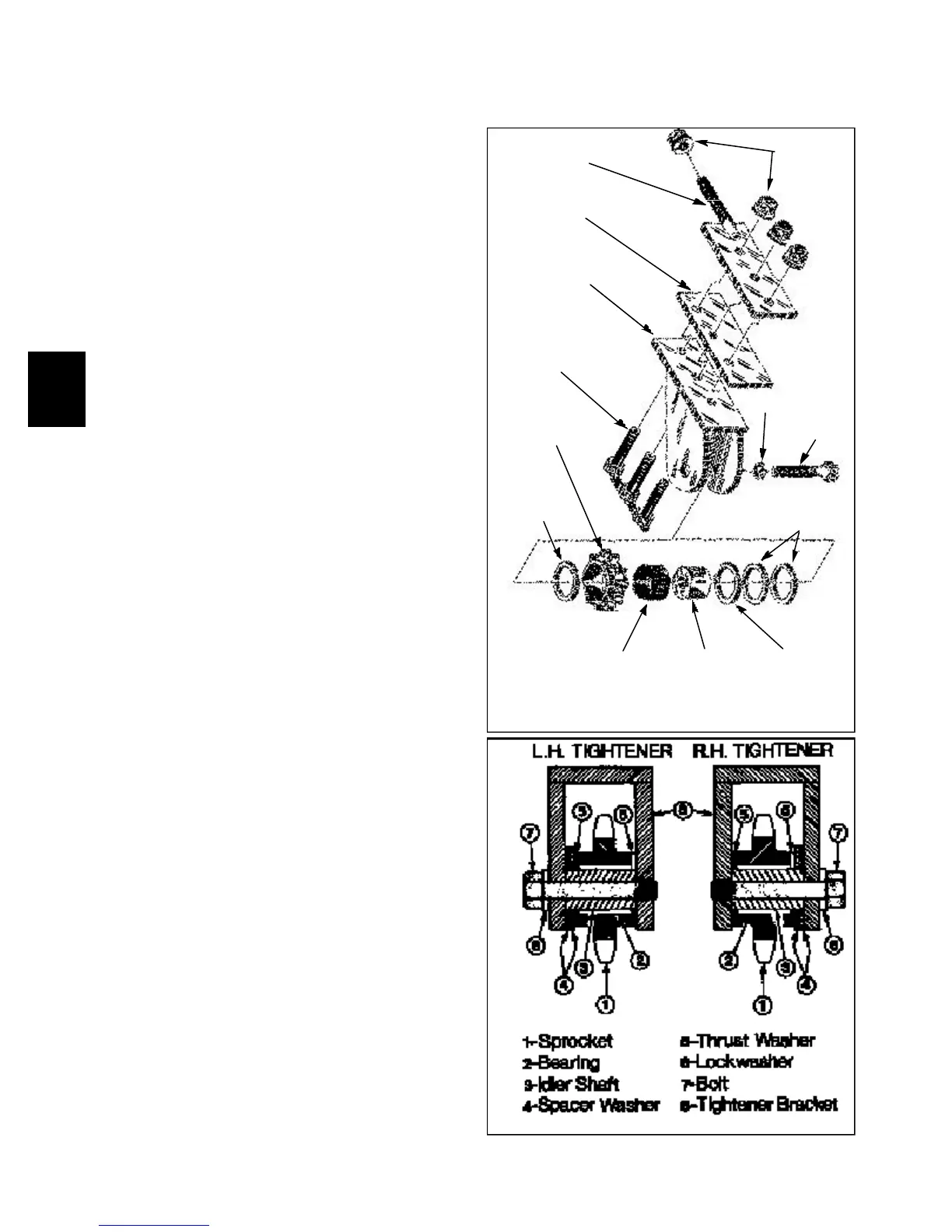

C1173

Adjuster plate

Support plate

Tightener bracket

(L.H. & R.H.)

Tightener bolt

assembly

Sprocket

Thrust

washer

Cage roller

bearing

Idler shaft

Spacer

washer

Thrust

washer

Bolt

Lock washer

Flange nut

Inspection

Follow fig. C1173 to disassemble the chain tightener

assembly. Note the finely machined thrust washers used

on either side of the sprocket. The 2 spacer washers are

used to align the sprocket with the axle sprocket and

chain. The spacer washers are always used next to the

head of the bolt, away from the threaded side of the tight-

ener bracket.

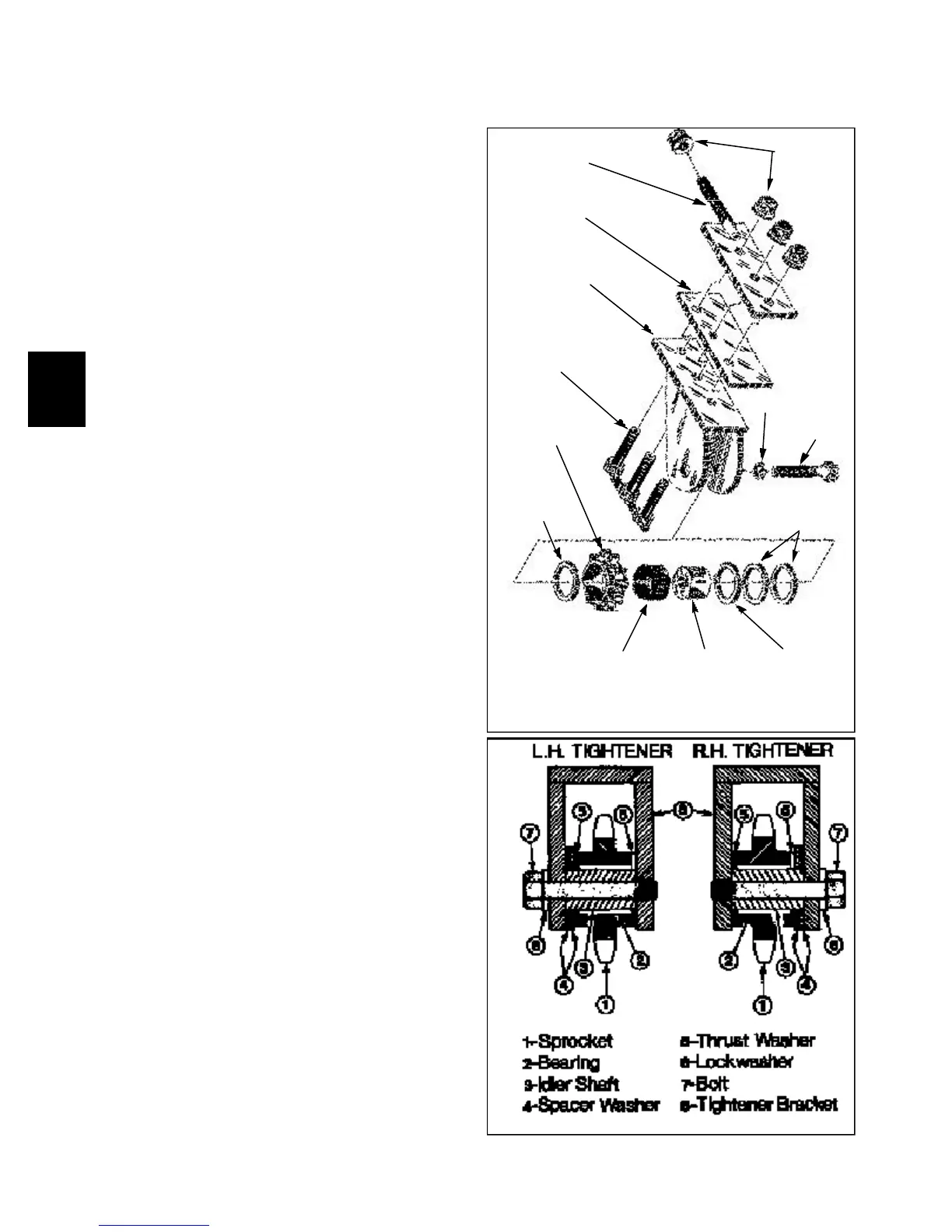

Inspect the thrust washers, sprocket, sprocket bearing sur-

face, bearing and idler shaft for scaring or excessive wear.

Replace worn parts as required.

When assembling the new components, use Loctite type

609 (red) to the threaded area of the tightener bracket

assembly. Torque the bolt to 180 lbs/ft (245 nm).

C233

R.H Tightener Assembly Shown

Loading...

Loading...