1-12

Assembly 137/153

GEAR PUMP 1.2

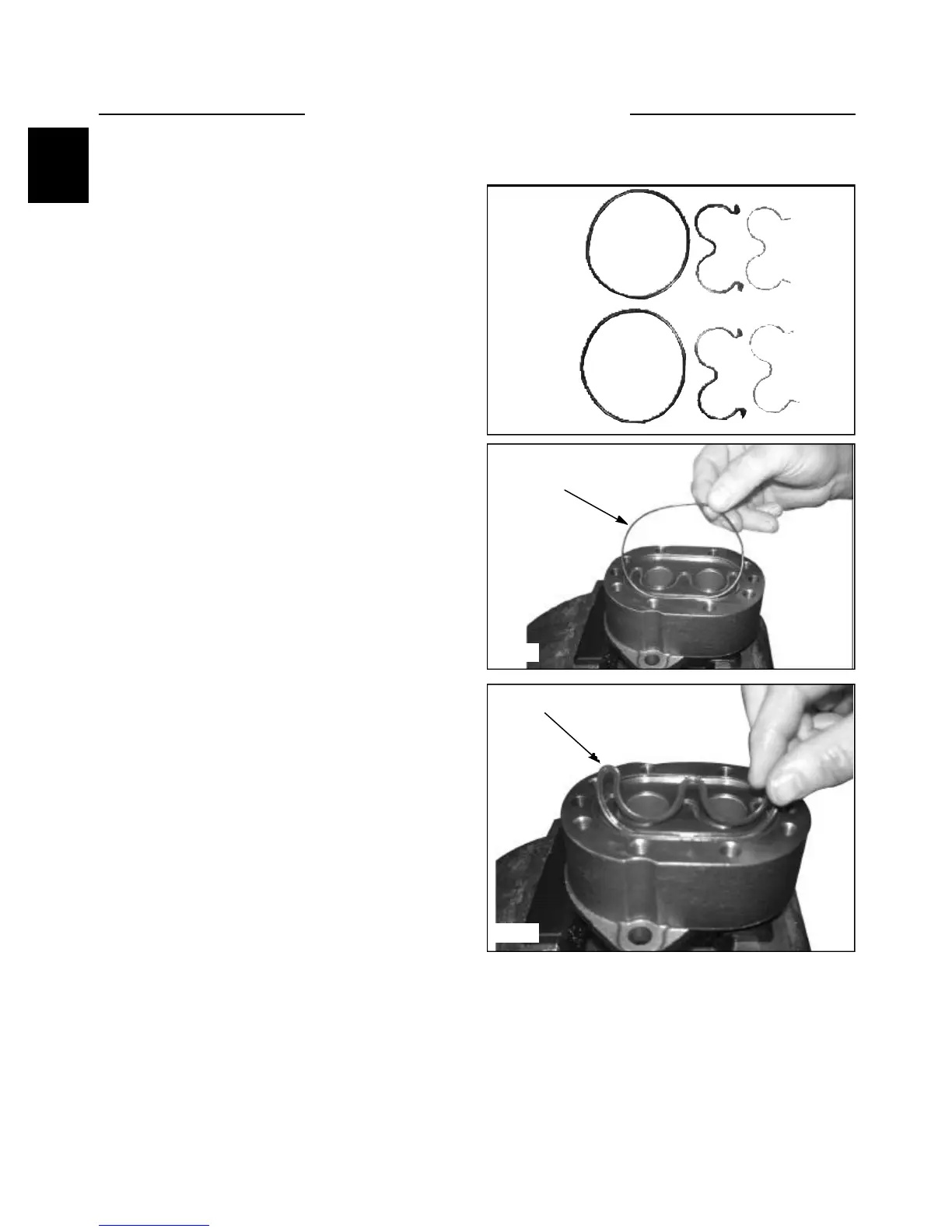

1. Have the entire seal kit available and lay out

neatly on the table (fig. C3980). Compare the old

seal kit to the new one to ensure you have the correct

one. Lightly coat all seals with seal grease. The

grease is needed to adhere the seals in their grooves.

DO NOT INSTALL DRY SEALS!

2. Prepare the body by cleaning it. Inspect the

internal and mating surfaces. Ensure the surfaces are

free of burrs and scratches.

3. Install the shaft seal into the body assembly (if

applicable). Prepare the body and shaft seal by

lightly lubricating with grease. Seat the seal in

the body assembly by hand. Then, using a shaft seal

installation tool press the seal until the tool stops on

the flange. This will insure the seal is inserted to the

proper depth.

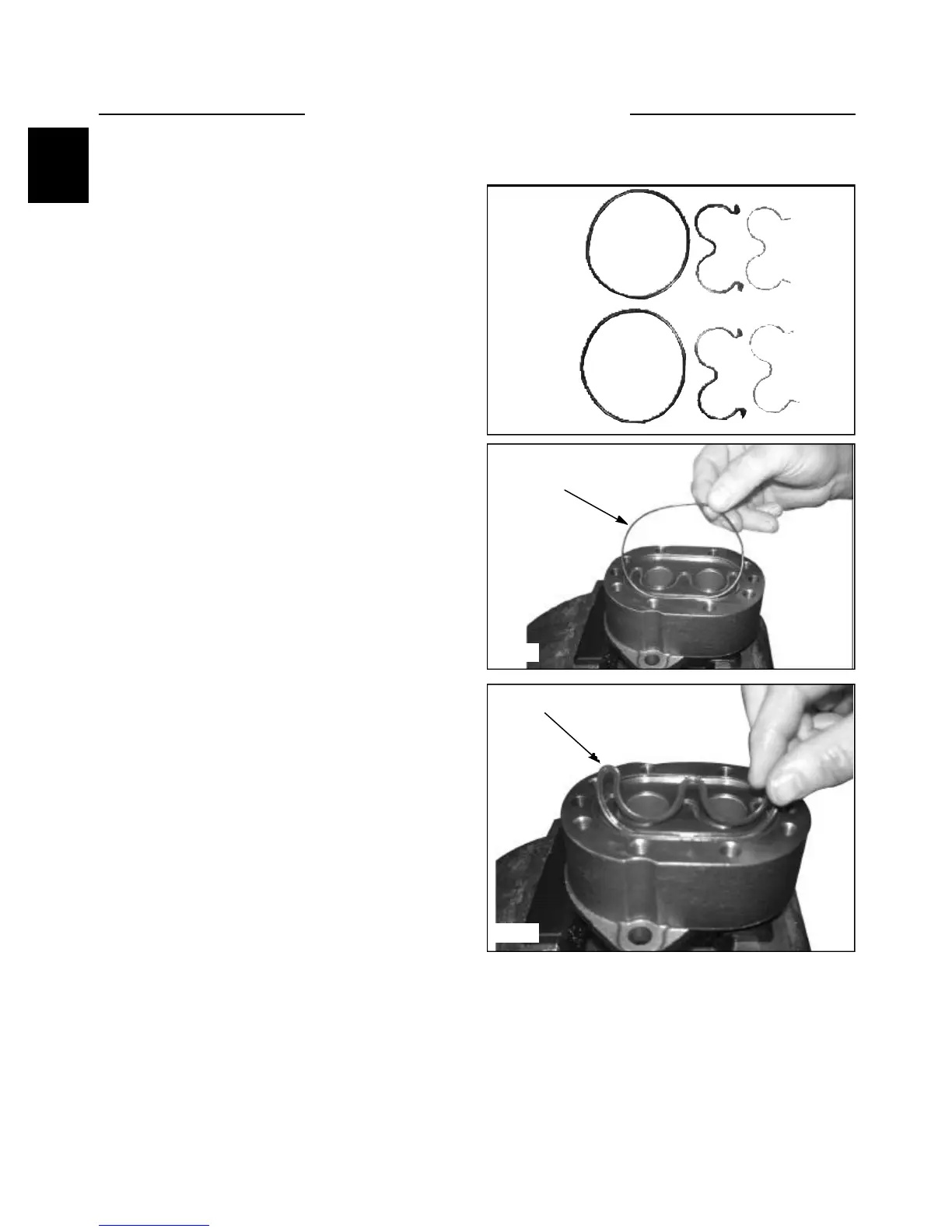

3. Place the body assembly, with the E- ring seal

grooves facing up, into a vice with soft jaws.

Caution must be used when using a vice to avoid

distorting or damaging the mounting pilot.

4. Place the rubber seal ring in the body groove.

(fig. C4359)

5. Place the pre-load seal (black rubber E-ring) into

the body E-ring groove. (fig. C4360)

C3980

C4359

C4360

Seal Ring

Pre-Load Seal

Loading...

Loading...