1-13

C4356

C4353

GEAR PUMP 1.2

Assembly 137/153 (cont’d)

6. Place the load seal directly on top of the pre-load

seal (blue E-ring).

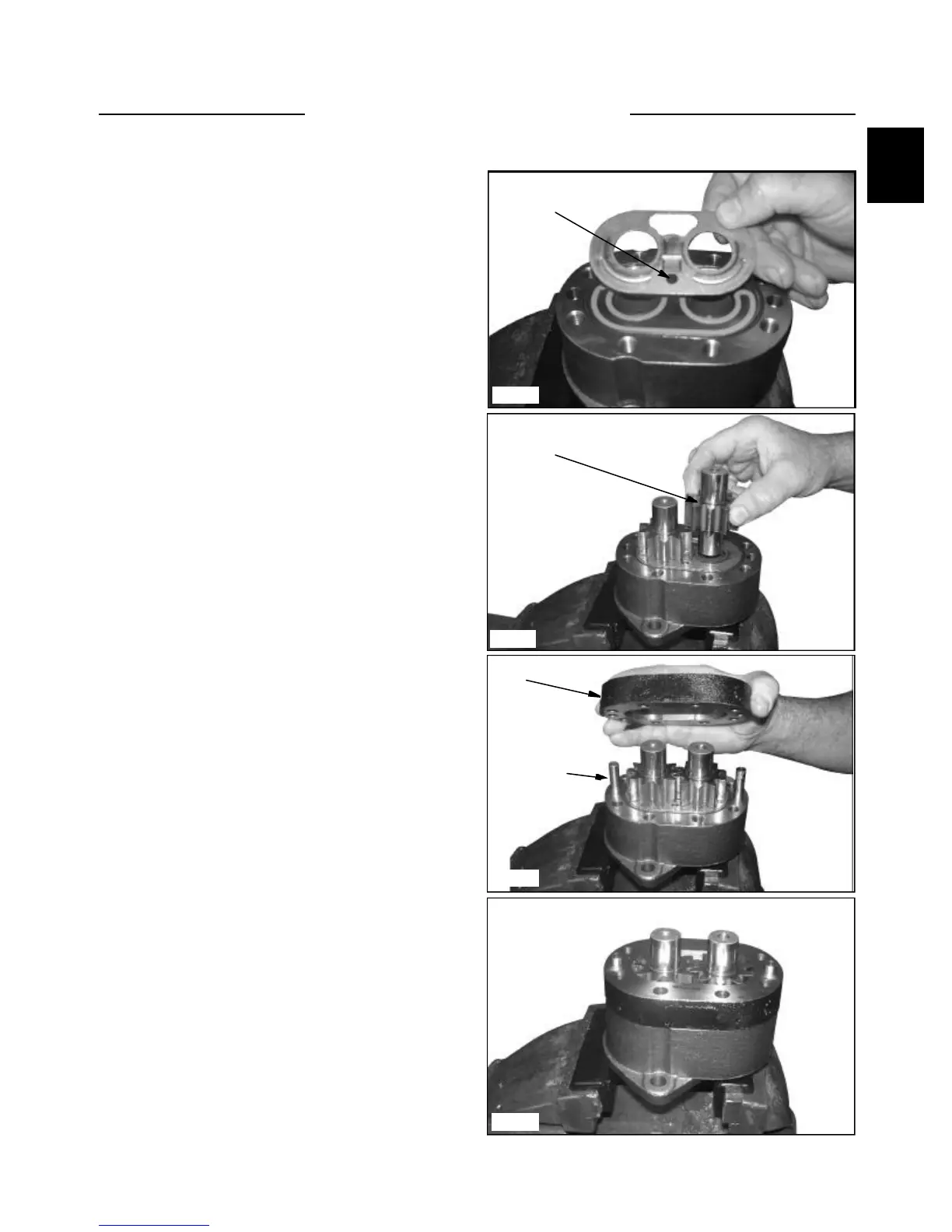

7. Find the wear plate with a 0.25” diameter

pressure hole and no oblong holes on the inlet side.

Place the wear plate on top of the load ring with the

bronze side facing up towards the gear. The 0.25”

pressure hole is to be positioned on the E-ring side of

the body. (fig C4356)

8. Lubricate the spline end of the drive shaft with

Aerolube grease. Insert the drive shaft in the correct

bearing bore. Align the idler shaft with the assembly

marks to ensure assembly is installed with the same

orientation as before assembly. Place the idler shaft

in the correct bearing bore into the body (fig.

C4354). Inspect gear teeth for alignment.

Misaligned gear teeth may increase operating noise.

Lubricate the complete gearset using clean light oil.

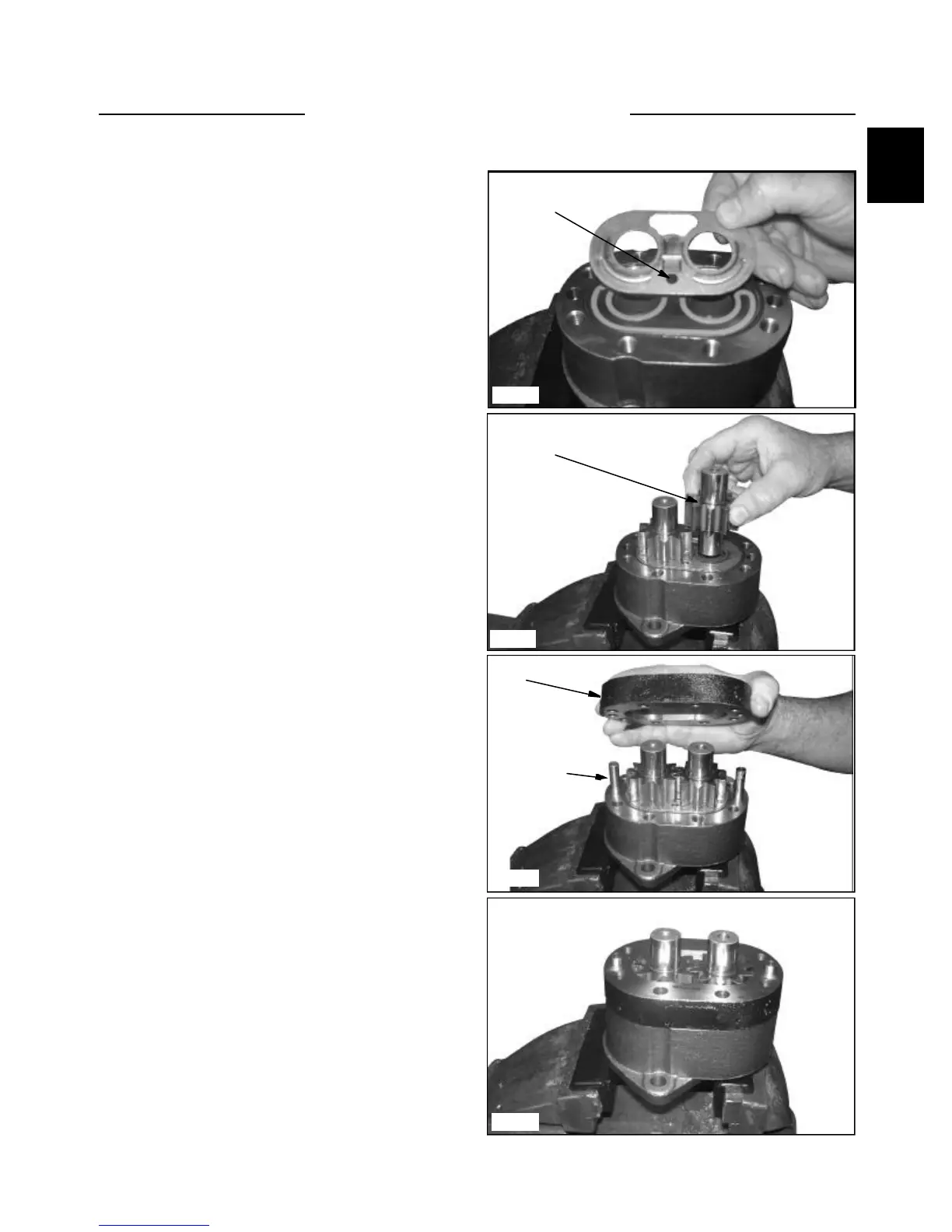

9. Insert the two dowel pins into the body

assembly. Place the gear plate over the dowel pins

and lightly tap making sure it contacts the body. (fig.

C4353) Check to make sure the gear plate is seated

properly with no foreign pinched between these

surfaces.

Wear plate with

0.25” pressure hole

C4354

Idler shaft

C4361

Dowel pin

Gear plate

Check seal

Loading...

Loading...