1-14

C4362

C4352

GEAR PUMP 1.2

Assembly 137/153 (cont’d)

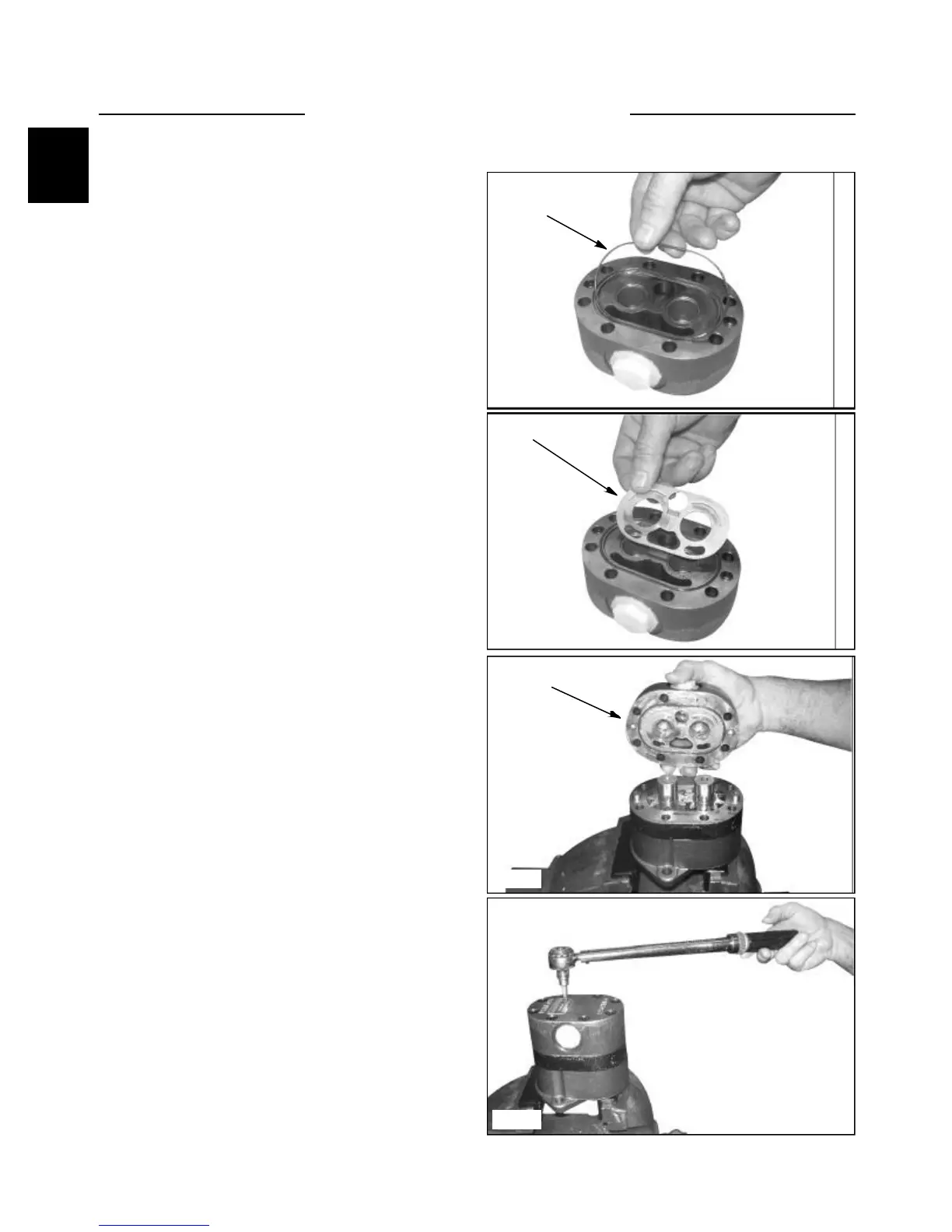

10. Place the cover assembly on a bench with the

machined surface facing up. Place the rubber seal

ring in the cover seal ring groove. (fig C4362)

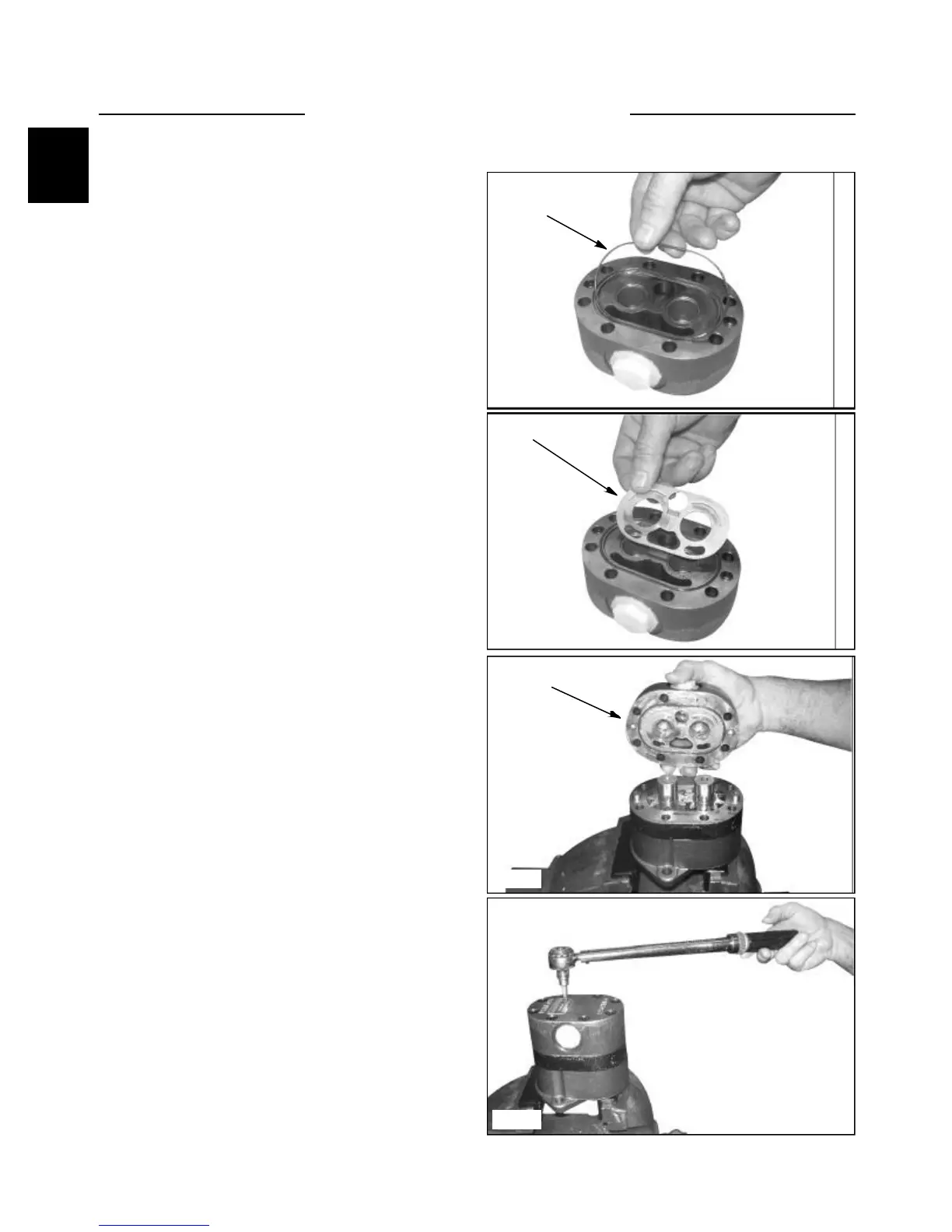

11. Find the wear plate with the 0.625” diameter

pressure hole and two oblong holes on the inlet side.

Position the wear plate in the cover with the bronze

side facing up (towards gears) and the 0.625”

pressure hole located over the circular holes in the

cover. (fig. C4352)

12. Line up the cover assembly with the shaft

journals and dowel pins (fig. C4351). Lightly tap the

back of the cover until dowel pins are completely

engaged. Check the seal making sure it is seated

properly with no foreign material pinched between

the surfaces.

13. Place the screws in the cover holes and turn until

the treads engage. Use care so that cross threading

does not occur.

14. Torque the four bolts in a crossing pattern a little

at a time until you reach the final torque of 47 ft lbs.

(65 Nm) (fig. C4363)

15. After the pump has been disassembled and

reassembled it it suggested that the pump be run in

and tested on an appropriate test stand. This is done

to verify the volumetric efficiency and the integrity

of the unit.

Seal ring

C4351

C4363

Wear plate

Cover assembly

Loading...

Loading...