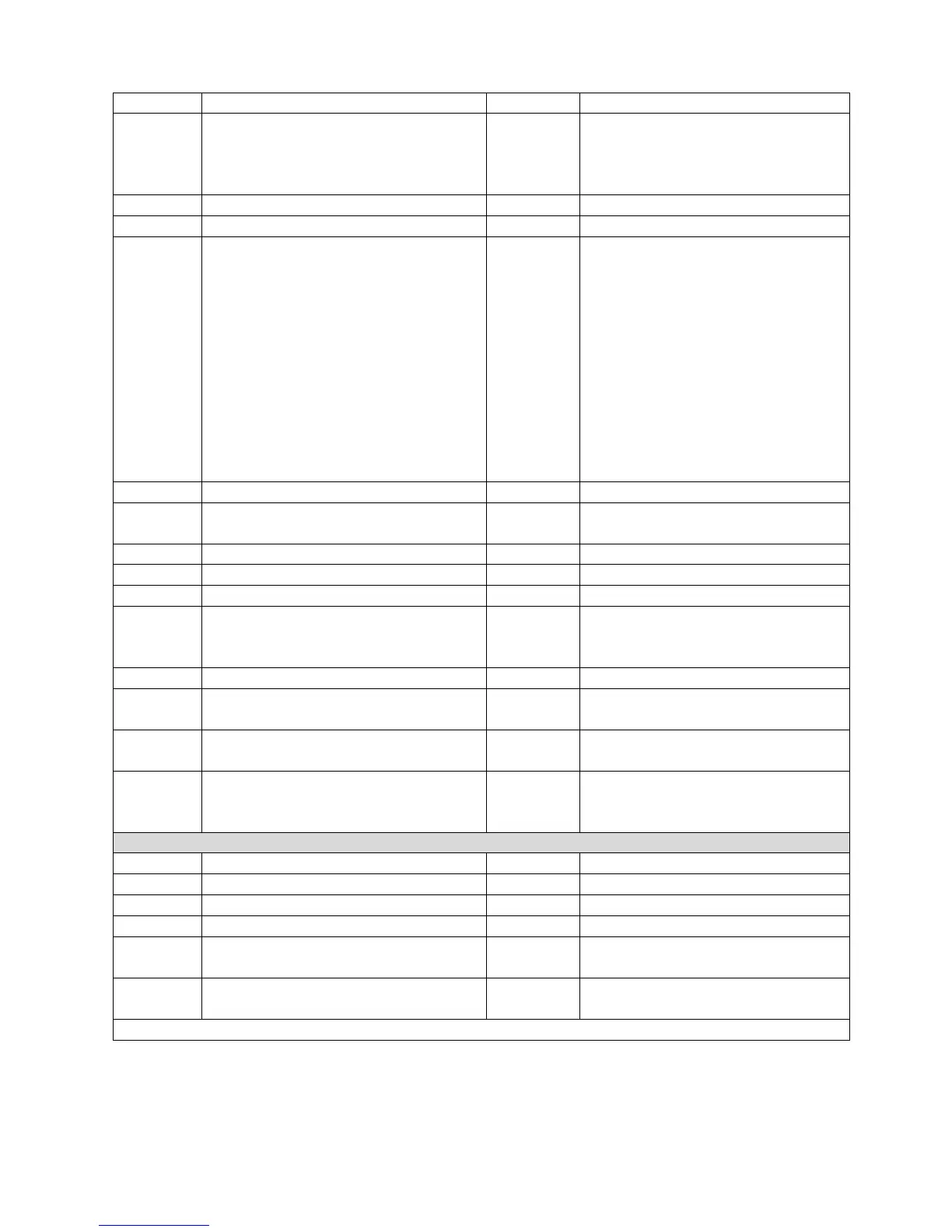

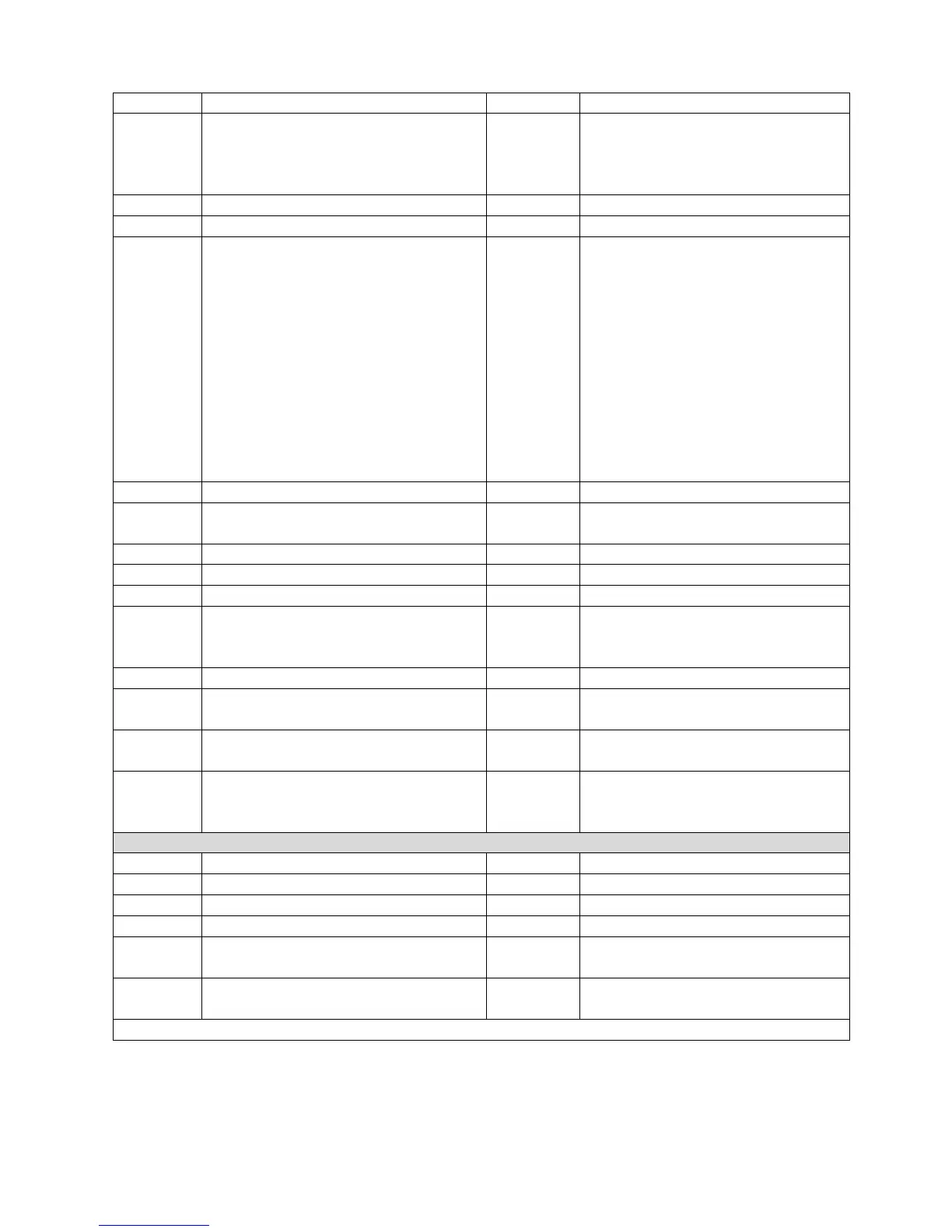

Begin of hysteresis test where:

x- delay time [sec] before return,

y-n times repeat (‘0’ for only cycle,

‘1’ for two, ect.

Start driving to ‘Endpos’ or

‘F limit S’ and after delay time ‘x’

drive back to the start pos. and

repeat ‘y’ times.

Reboot & start SCIA bootloader

Condition of machine

Bit #0 fast (jog keys active)

running ; (test is running)

schleppf ; (motor contouring

error

kraftmode ; (CFR active)

ref_sw ; (option)

endsw_dn ;

endsw_up ;

overload ; (load cell overload)

Up Dir ; (driving up)

Motor -Error; (servo off-line)

OTW- Warning;

Door- open; (option)

Bit #12 Reference;

Ask for user serial number

Set user serial number (max 20 char,

can be used to keep machine ID)

Ask for software version no.

Ask for active units (1-SI, 2-US)

Set perforce speed (used when ‘

Perforce speed’ enabled in service

menu.

Move to position (no position info)

Move to absolute position (with pos

info)

Move to relative position (with pos

info)

Relative, 20mm to up from actual

position.

Set ‘Start Position’ used when Ref

mode >0

Machine after “Return” order drive

back to 50mm (not to “0”) if Ref

mode >0

Special commands to reload configuration data of the load cell

1)

Set “nominal value” of the Load Cell

Set “mV/V” value of the Load Cell

Set calibration factor of the Load Cell

Set F limit F value of the Load Cell

Set display precision (1 or 2)

Prec = 2 (2 places after decimal

point of force values).

Set DIGITS value for motor encoder

DIGITS = 10512 (pulses/mm)

(for BLDC motor is 6080 p/mm)

1)

When command C? xxx is send without parameter (i.e.: CN$) then you get back actual parameter.

Loading...

Loading...