47

SWIMSPEED CONTROL INSTRUCTIONS (EP-16)

1. Adjust Up or Down as needed for preference 2. Turn Power On

MAINTENANCE

Perform maintenance every 9-12 months.

1. Disconnect power

2. Take panel away

3. Drain water down to benches

4. Visually check Hydro hoses for cracks in connections

and for leaks. If any are present call DEALER.

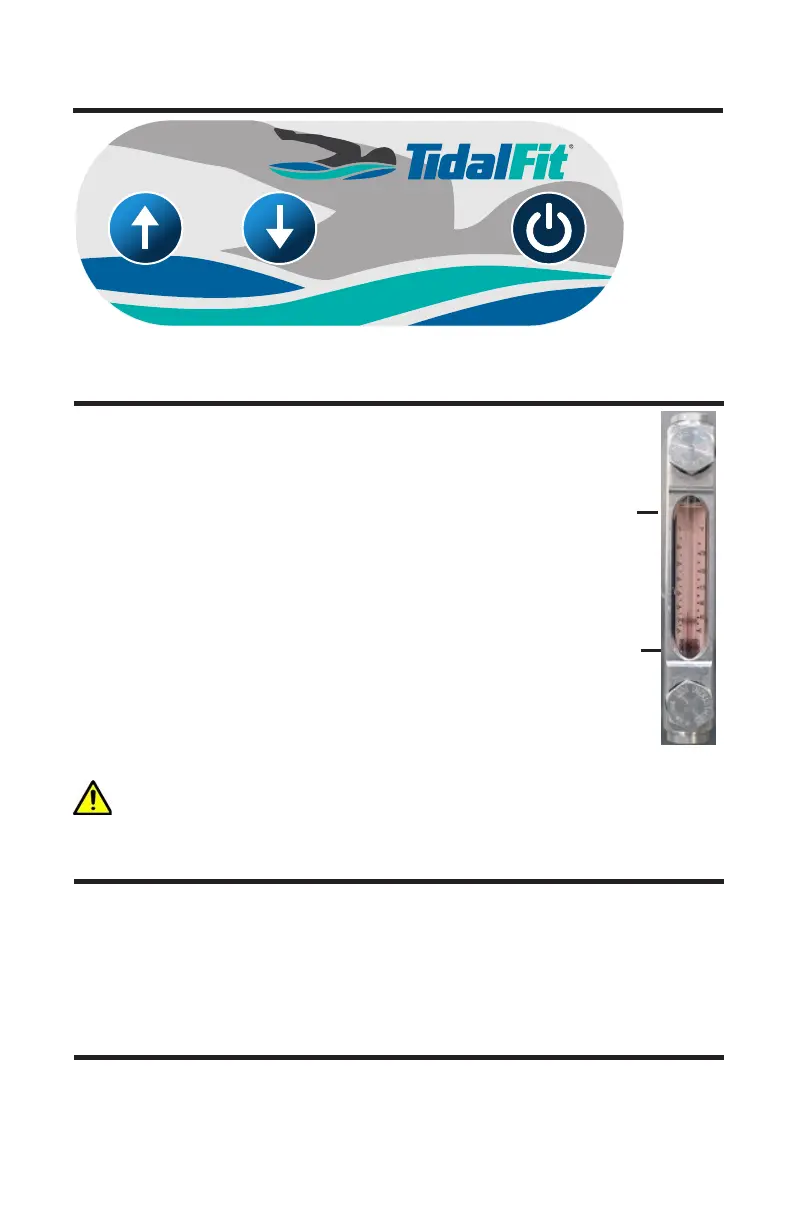

5. Visually check Hydro Fluid Level -Make sure

glycol is at proper level (FULL in sight glass)

6. Add fresh water

7. If temp reading is below 100

o

C call DEALER

8. Reconnect power

WARNING

This system must be wired by a certied electrician.

Wiring diagrams are located inside the control box to aid

in the installation.

CAUTION: Hydraulic Lines are under pressure.

REQUIRED VOLTAGE FOR CONTROL BOX

A 40A/220 volt single phase service is required to operate. This service

should be connected by a certied electrician to the control box accoring

to the enclosed wiring diagram. The control is a (VFD) Variable Frequency

Drive which converts 220 volt single phase input power to 220 volt three

phase output power to drive the Hydraulic Water Current Motor.

HYDRAULIC WATER CURRENT MOTOR

The hydraulic water current motor input power is 220 volt three

(3) phase This motor must be wired as shown in the enclosed diagram

failure to do so will result in PERMANENT damage to the electric motor

and void all warranties.

(Top level)

(Bottom level)

Loading...

Loading...