7000 Series Disc Harrows 28 Titan Implement, LLC

January 2022 (423) 334-0012

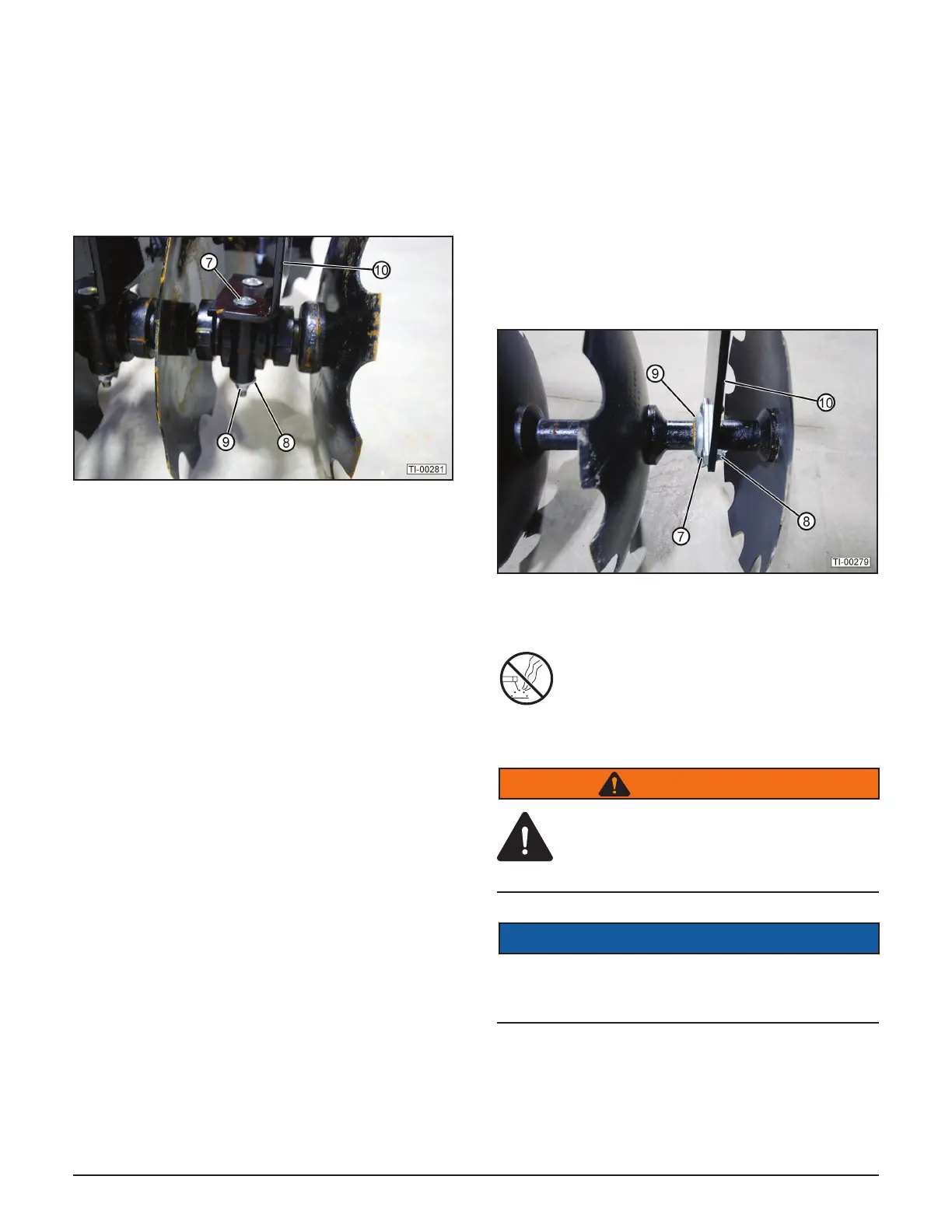

8.4 Bearing Replacement

8.4.1 7100 Series Bearing Cap Replacement

1. Remove bearing mount following Steps 1-3 in “8.3.1

7100 Series Disc Blade Replacement” on page

27.

2. Remove carriage bolts (7), lock nuts (8), and at

washers (9) from bearing hanger (10).

3. Separate and remove the bearing cap halves.

4. Install the new bearing cap halves using the

carriage bolts, washers, and locknuts previously

removed.

5. Reassemble gang with new bearing. Assemble in

reverse order of disassembly.

NOTE: Maintain proper order of discs, spacers, and

bearing mounts for reassembly.

6. Secure gang assembly to the frame using carriage

bolts (1) and locknuts (2) previously removed.

7. Grease the zerks on the new axle bearing caps.

This would be a good time to grease the remaining

axle bearing caps as well.

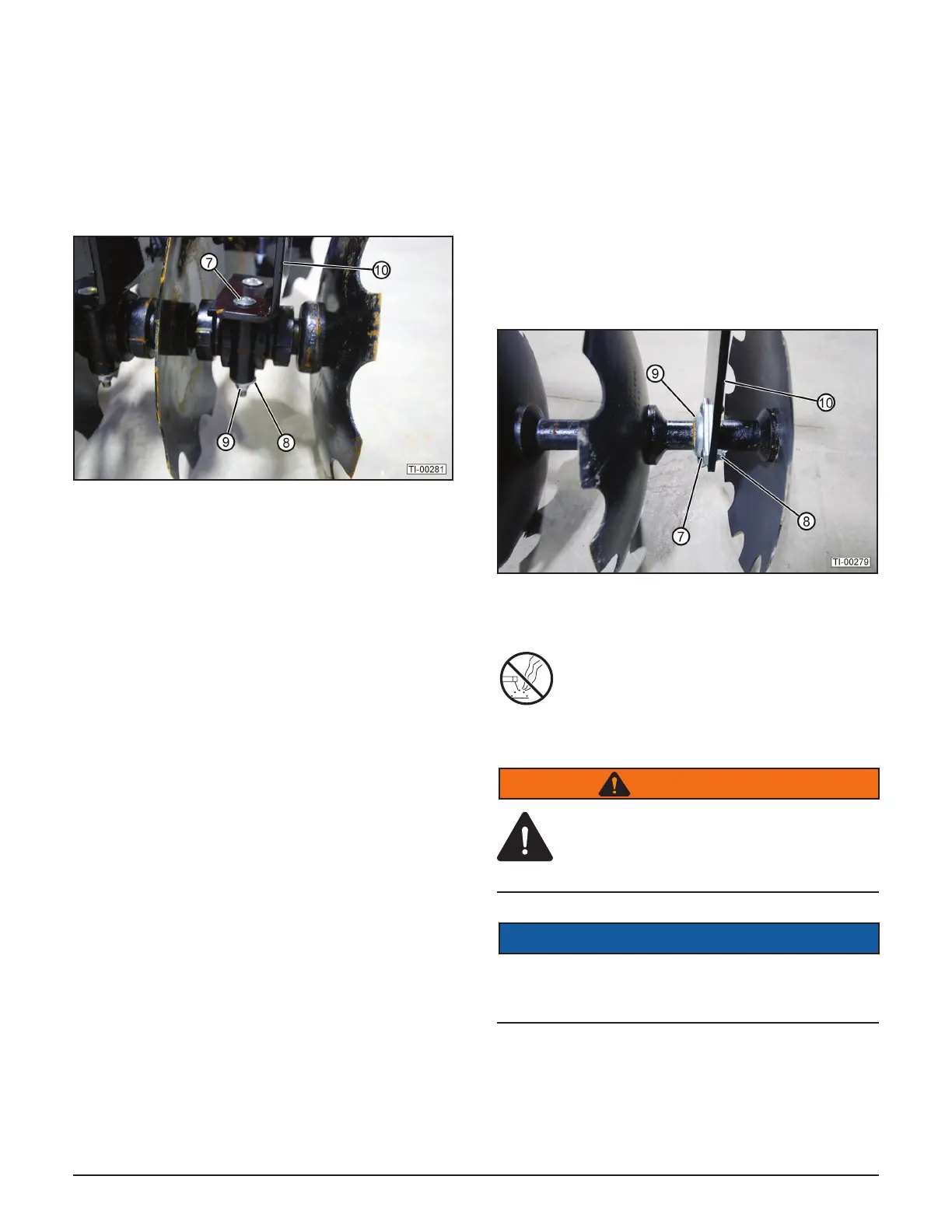

8.4.2 7300, 7400 Series Bearing Replacement

1. Remove and disassemble the disc gang following

Steps 1-3 in “8.3.2 7300, 7400 Series Disc Blade

Replacement” on page 27.

2. Reassemble the disc gang with new bearing (9).

Assemble in reverse order of disassembly.

NOTE: Maintain proper order and orientation of discs,

spacers, and bearings for reassembly.

3. Secure the disc gang assembly to the bearing

hangers (10), using carriage bolts (7), and lock nuts

(8) previously removed.

8.5 Welding Repairs

Before performing any type of welding repair

to the disc harrow, contact Titan Implement for

approval. Repair welding must be done with

care and with procedures that may be beyond the

capabilities of the ordinary welder.

Personal Injury Hazard

Repairs or modications to the disc harrow

can result in serious injury or death should

these repairs fail.

Anyone performing a welding repair should be certied

in accordance to the American Welding Society (AWS)

standards.

Loading...

Loading...