Titan Implement, LLC 29 7000 Series Disc Harrows

(423) 334-0012 January 2022

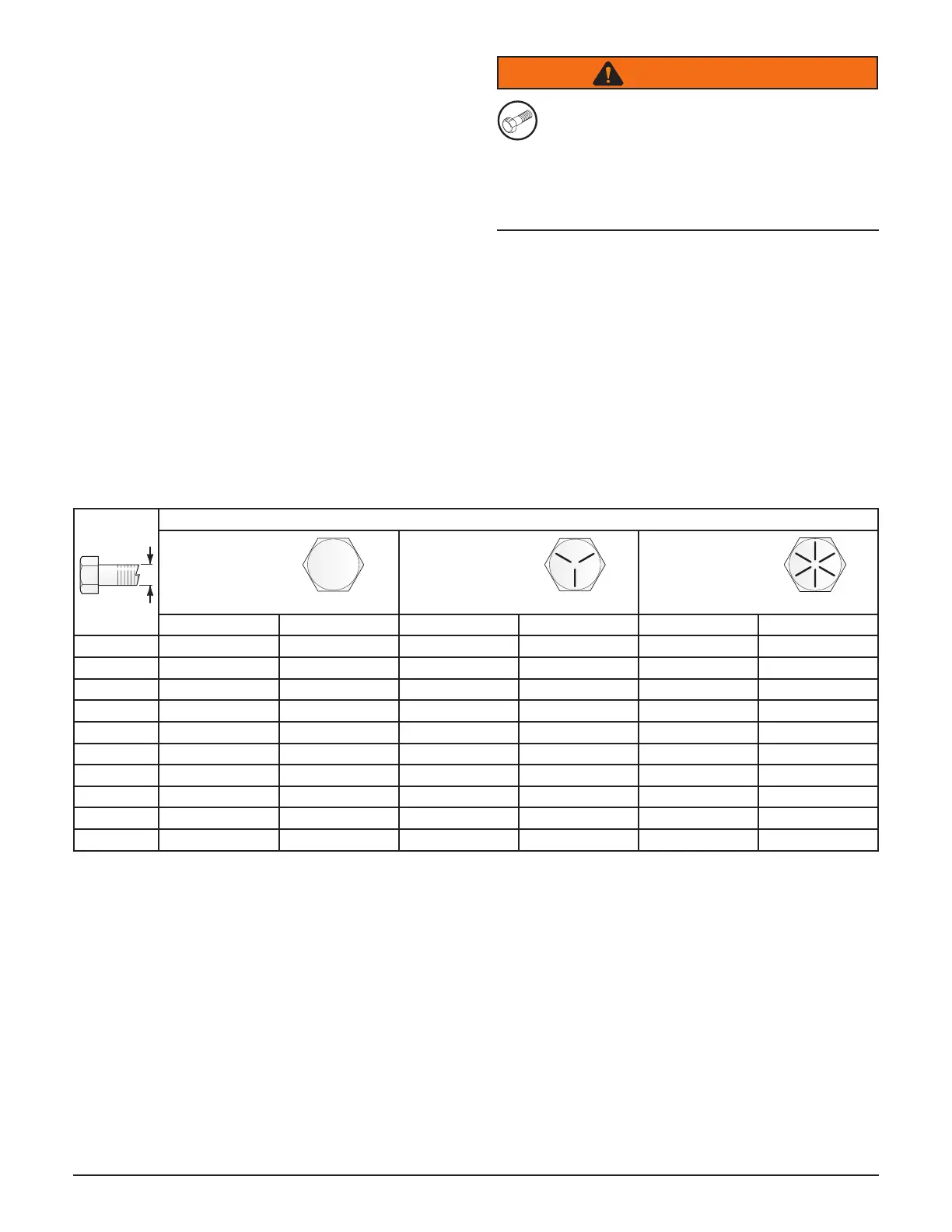

8.6 Bolt Torque Requirements

It is extremely important to apply and maintain proper

torque on all bolts. Use a torque wrench to assure

the proper amount of torque is being applied to the

fastener.

Start all bolts or nuts by hand to prevent cross

threading.

Torque gures indicated in the chart are used for

non-greased or non-oiled threads and heads unless

otherwise specied. Therefore, do not grease or oil

bolts or cap screws unless otherwise specied in this

manual. When using locking elements, increase torque

values by 5%.

The chart below gives correct torque values for various

bolts and cap screws. Tighten all bolts to the torque

specied in the chart unless otherwise noted. Check

tightness of bolts periodically, using the bolt torque

chart as a guide. Always replace hardware with the

same Grade bolt.

Bolt

Diameter

English Bolt Torque Specifications

Grade 2

Grade 5

3 Radial Lines

Grade 8

6 Radial Lines

N·m ft.lbs. N·m ft.lbs. N·m ft.lbs.

1/4" 8 6 12 9 17 12

5/16" 13 10 25 19 36 27

3/8" 27 20 45 33 63 45

7/16" 41 30 72 53 100 75

1/2" 61 45 110 80 155 115

9/16" 95 60 155 115 220 165

5/8" 128 95 215 158 305 220

3/4" 225 165 390 290 540 398

7/8" 230 170 570 420 880 650

1" 345 225 850 630 1320 970

OEM

EQUIPMENT FAILURE

The torque value for bolts and cap screws are

identied by their head markings. Replacing

higher “Grade” bolts (Grade 5) with lower Grade

bolts will lead to equipment failure and can result in

injury or death. Always use replacement bolts with

the same Grade markings as the removed bolt.

Loading...

Loading...