Installation

Installing TS-i4 Blade Sensor

2-4

P/N: 1049060-01

12. Weld the 4 Hole Weld-on plate (Figure 2-3 on page 2-2) to the back of the dozer blade, using a

suitable welding method (Wire Welding or Stick Welding), weld the 4 Hole Weld-on plate to the

back of the dozer blade. The weld leg size should be 6 mm (1/4 inch), and weld lengths should

be at least 50 mm (2 inches).

13. Remove any weld slag using a slag hammer or other suitable tool. Clean off the weld by

scrubbing with a wire brush to prepare it for painting.

14. Paint the plate and welds with a rust-preventive paint in a color matching the machine to

prevent rust and corrosion.

15. Secure the TS-i4 Dozer Base Platform bracket to the weld-on plate using the supplied M10

bolts and washers.

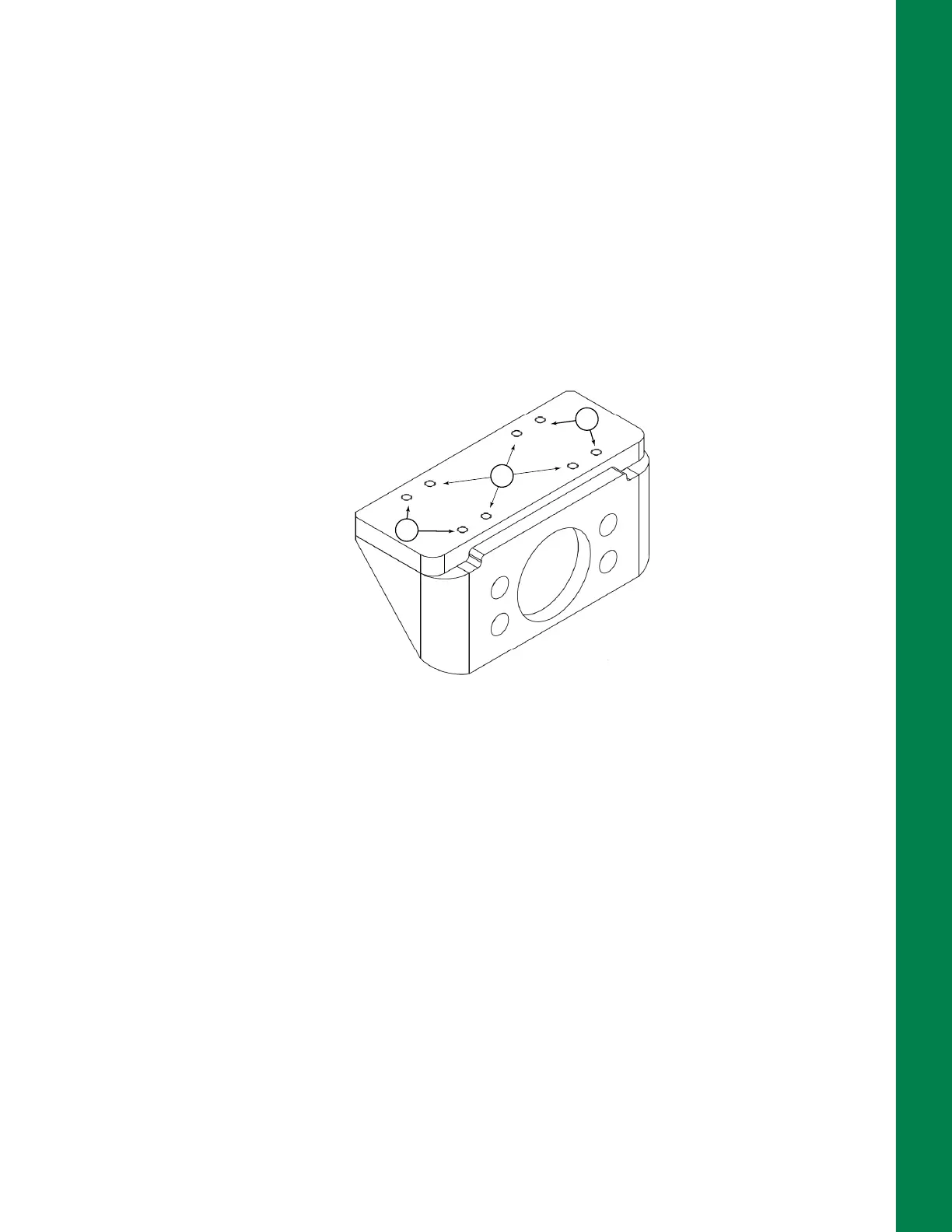

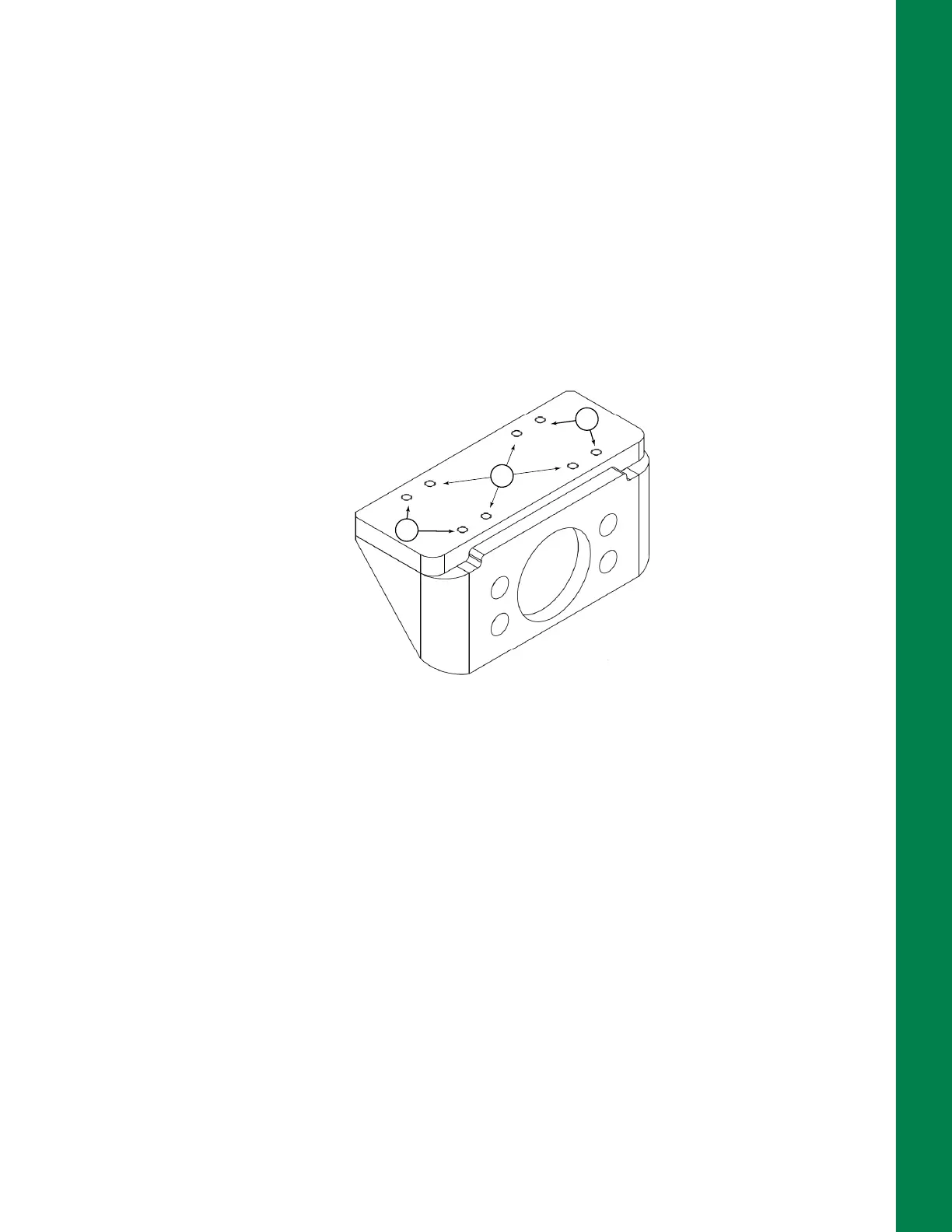

16. Mount the TS-i4 IMU sensor to the TS-i4 Dozer Base Platform bracket, using two inside pairs

of drilled holes (A) and the supplied hex screws (Figure 2-6).

Figure 2-6: Drilled Holes in TS-i4 Dozer Base Platform Bracket

17. Use two of the standoffs to secure one strain relief plate to the TS-i4 Dozer Base Platform

bracket using drilled holes (B) as shown in Figure 2-6. The strain relief plate should face

towards the center of the blade.

18. Use one flat M6 washer as spacer under each standoff on the side with the terminator. Screw

the standoffs into the TS-i4 Dozer Base Platform bracket (Figure 2-3 on page 2-2).

19. Attach the terminator to the outside connector of the TS-i4 IMU sensor (Figure 2-3 on

page 2-2).

20. Ask the operator to move the blade through the entire range of blade positions. Determine the

length of protective hydraulic hose needed to protect the M12 cable from the TS-i4 Blade

sensor to the planned location of the TS-i4 C-Frame sensor.

21. Cut the protective hydraulic hose to the required length.

22. Determine where to position the provided weld-on hose clamps to secure the protected M12

cable from the TS-i4 Blade sensor.

23. Weld the weld-on hose clamps.

24. Thread the M12 cable for the TS-i4 Blade sensor through the protective hydraulic hose.

Loading...

Loading...