Tab 15. Device specific parameters

5) FUNCTIONAL SAFETY RELEVANT SPECIFICATIONS

5.1 Application and Environmental Limits

The tested device is intended for media such as Gas and Fluid. The applicable fluid shall be clean and non-corrosive fluid.Required

Air-quality-level in accordance to ISO 8573-1: 7–1–4 for particles – water – oil. The tested device is rated up to 4 bars and up to 8 bars.

For the detailed materials of construction of tested device, please refer to user manual, operation instruction, maintenance instruction.

The pneumatic actuator is intended for use in Indoor, Outdoor and/or Hazardous Area (ATEX II 2GD c T4) at temperaturerange of

–20 °C to 80 °C.

5.2 SIL Capability

The actuators are suitable for use in a safety instrumented system up to SIL 2 (low demand mode). Under consideration of the minimum

required hardware fault tolerance HFT = 1 the actuators may be used in a redundant architecture up to SIL 3.The development and

manufacturing process and the functional safety management applied by the manufacturer in the relevant lifecycle phases of the

product has been inspected and assessed as suitable for the use in applications with a maximum Safety Integrity Level of 3 (SC 3).

5.3 Requirements Of Other Components

In order to determine whether tested device is suitable for use in a certain safety-related system, it is necessary to determine the

PFDavg value of the overall system. Usually it is presumed that a final element (valve + actuator) uses up to 50 % of the total available

PFDavg value.

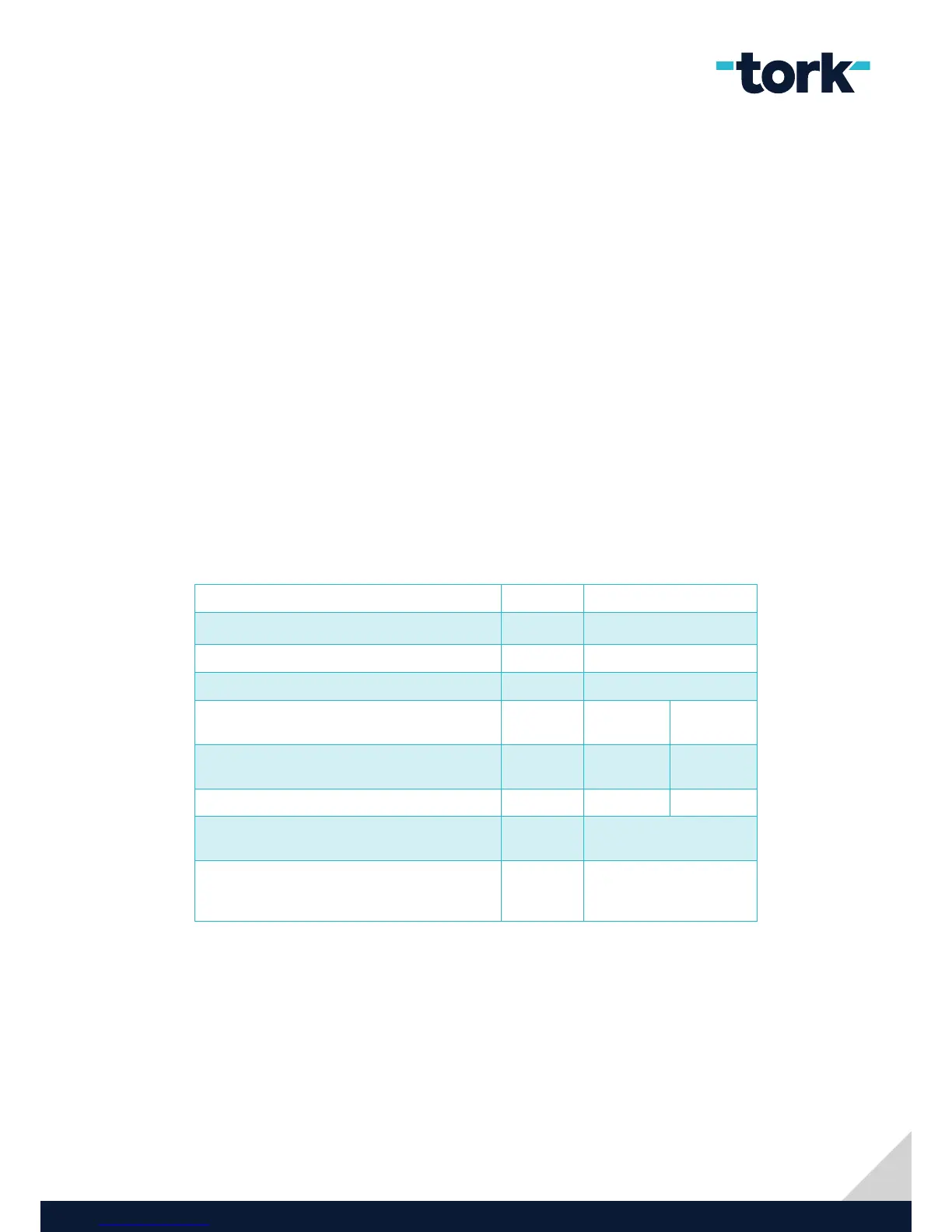

Route of Assessment 2H / 1S

Type of Sub-system Type A

Mode of Operation Low Demand Mode

Hardware Fault Tolerance

HFT

0

Lambda Dangerous

confidence level of calculation 1-α = 95 %

λ

D

3.50 E-07/h 350 FIT

Lambda Dangerous Undetected

assumed Diagnostic Coverage DC = 0 %

λ

DU

3.50 E-07/h 350 FIT

Mean Time To Dangerous Failure

MTTFD

2.86 E+06 h 326 a

Average Probability of Failure on Demand 1oo1

assumed Proof Test Interval T1 = 1 year

PFD

avg

(T

1

)

1.53 E-03

Average Probability of Failure on Demand 1oo2

assumed Proof Test Interval T1 = 1 year

assumed β1oo2 = 10 %

PFD

avg

(T

1

)

1.53 E-04

Loading...

Loading...