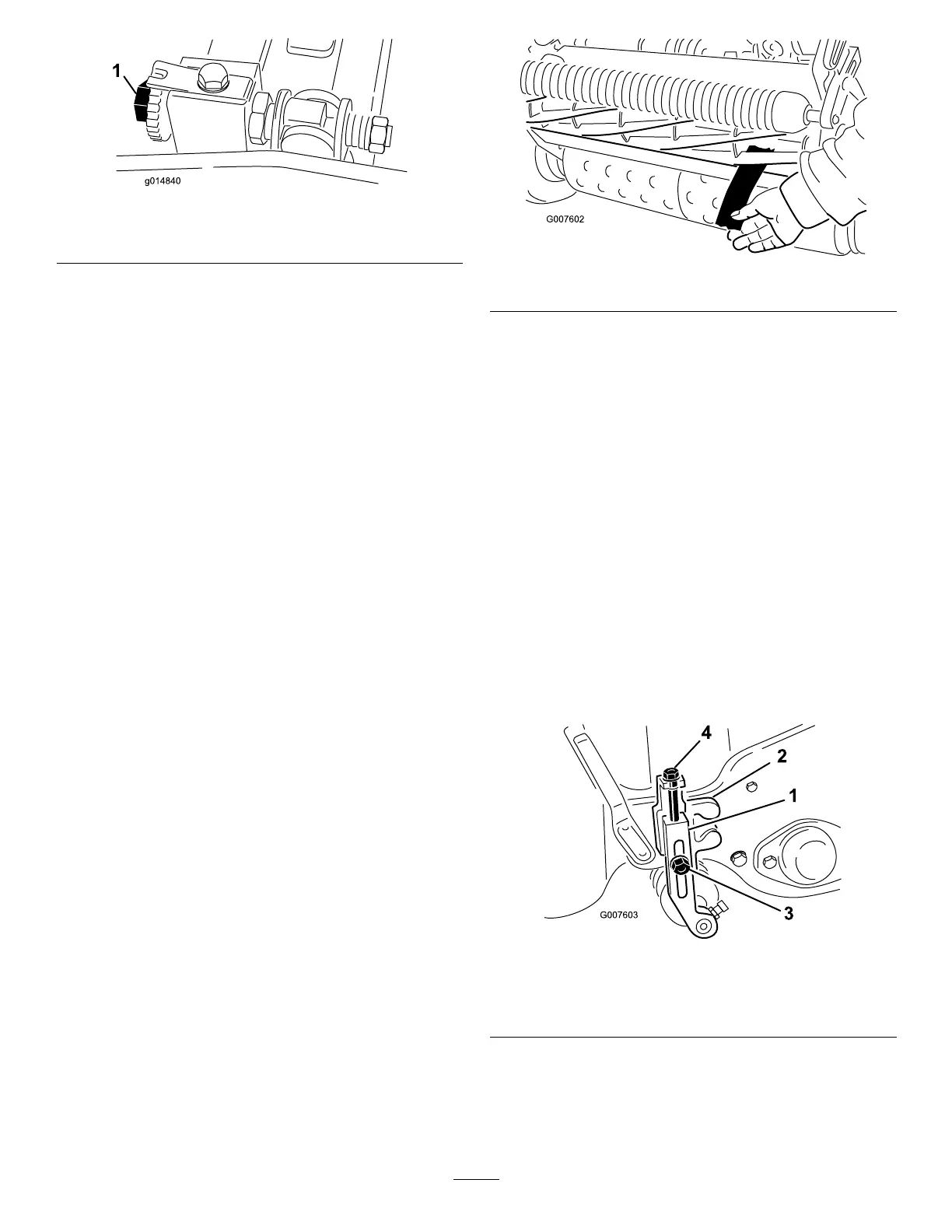

g014840

Figure52

1.Bedbar-adjustingscrew

4.Rotatethereelsothatabladecrossesthe

bedknifeedgebetweentherstandsecond

bedknifescrewheadsontherightsideofthe

cuttingunit.

5.Insertthe0.05mm(0.002inch)shimbetween

themarkedbladeandthebedknifeedgeat

thepointwherethemarkedbladecrossesthe

bedknifeedge.

6.Turntherightbedbar-adjustingscrewuntilyou

feellightpressure(i.e.,drag)ontheshimby

slidingitside-to-side(Figure52).

7.Removetheshim.

8.Fortheleftsideofthecuttingunit,slowlyrotate

thereelsothattheclosestbladecrossesthe

bedknifeedgebetweentherstandsecond

screwheads.

9.Repeatsteps4through7fortheleftsideofthe

cuttingunitandleftbedbar-adjustingscrew.

10.Repeatsteps5through7untillightdragis

achievedonboththerightandleftsidesofthe

cuttingunitutilizingthesamecontactpoints.

11.Toobtainlightcontactbetweenthereeland

bedknife,turneachbedbar-adjustingscrew

clockwise3clicks.

Note:Eachclickturnedonthebedbar-adjusting

screwmovesthebedknife0.018mm(0.0007

inch).Clockwiserotationmovesthebedknife

edgeclosertothereelandcounterclockwise

rotationmovethebedknifeedgeawayfromthe

reel.

12.T estthecuttingperformancebyinsertingalong

stripofcuttingperformancepaperbetweenthe

reelandbedknife,perpendiculartothebedknife

(Figure53).Slowlyrotatethereelforward;it

shouldcutthepaper.

g007602

Figure53

Note:Ifyouseeexcessivecontact/reeldrag,it

willbenecessarytobacklap,facethefrontof

thebedknife,orgrindthecuttingunittoachieve

thesharpedgesthatarenecessaryforprecise

cutting.

AdjustingtheHeight-of-Cut

1.Verifythattherearrollerislevelandthatthe

bedknife-to-reelcontactiscorrect.Tipthe

machinebackonthehandletoexposethefront

andrearrollersandthebedknife.

Important:Donottipthemachineatan

anglegreaterthan25°.Tippingthemachine

beyond25°leadstooilleakingintothe

combustionchamberand/orfuelleakingout

ofthefuel-tankcap.

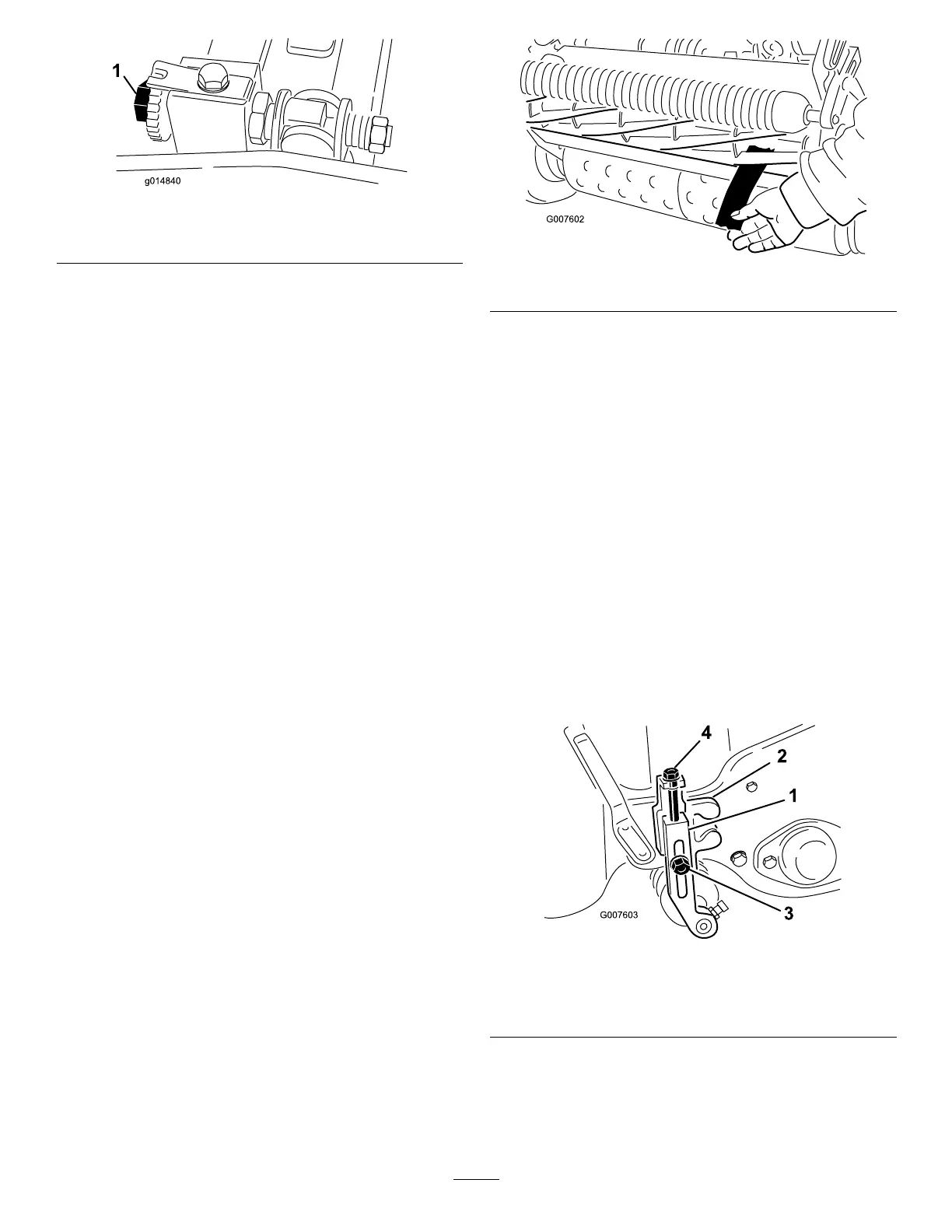

2.Loosenthelocknutsthatsecuretheheight-of-cut

armstotheheight-of-cutbrackets(Figure54).

g007603

Figure54

1.Height-of-cutarm

3.Locknut

2.Height-of-cutbracket

4.Adjustingscrew

3.Loosenthenutonthegaugebar(Figure55)

andsettheadjustingscrewtothedesired

height-of-cut.Thedistancebetweenthebottom

ofthescrewheadandthefaceofthebaristhe

heightofcut.

37

Loading...

Loading...