Groundsmaster 4100--D/4110--DCutting Deck

Page 8 -- 16

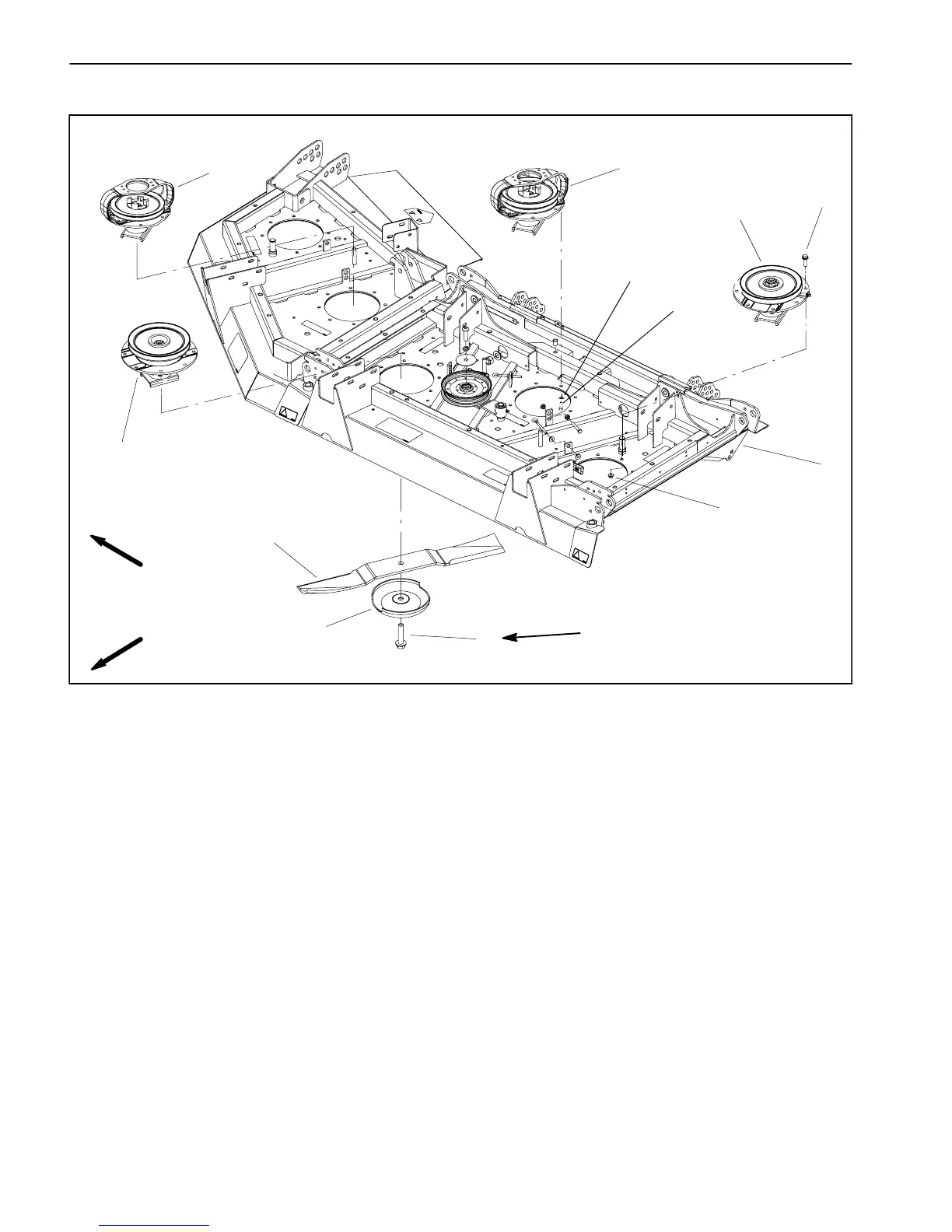

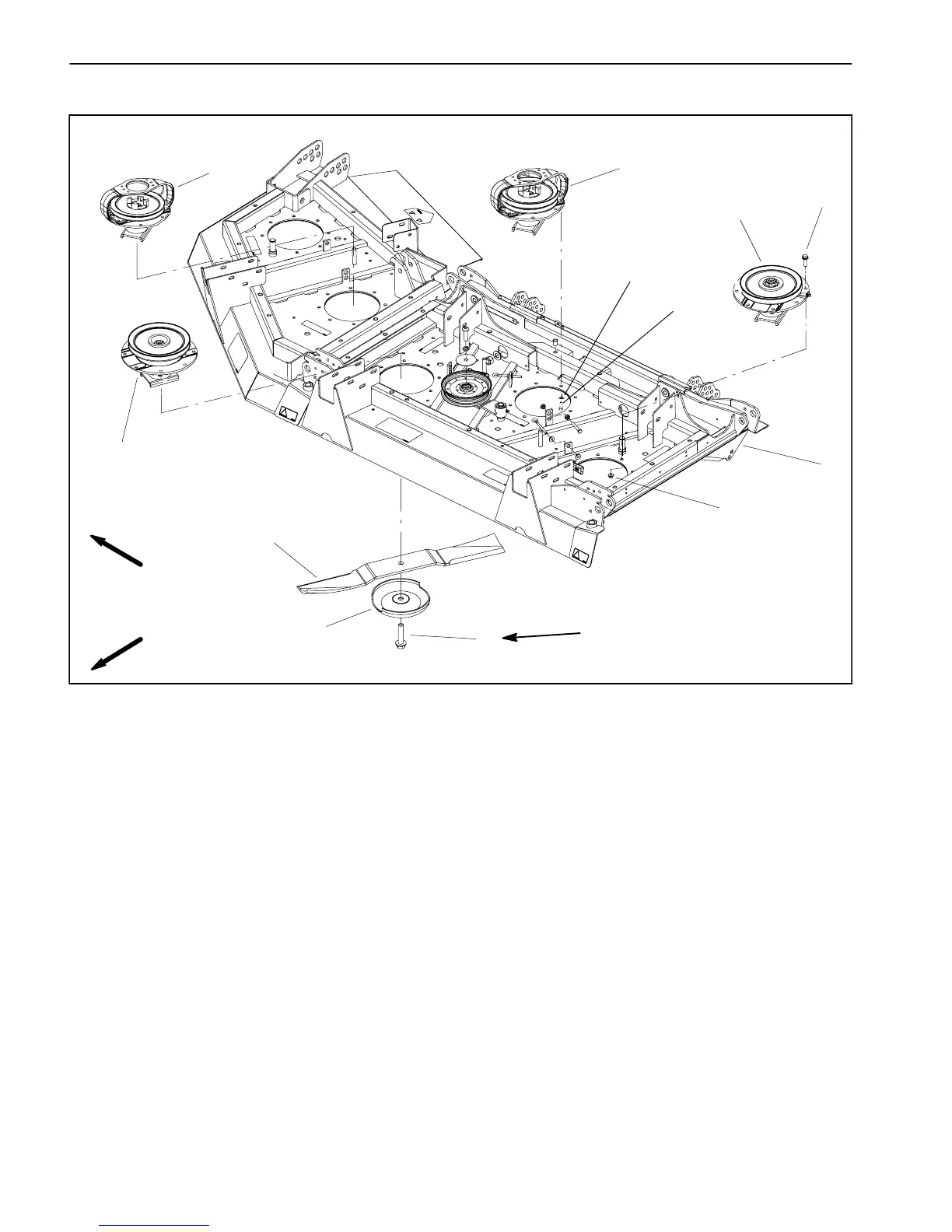

Blade Spindle

1. Cutting deck

2. Drive spindle: single pulley (2 used)

3. Low driven spindle (3 used)

4. Drive spindle: double pulley (1 used)

5. Flange head screw

6. Flange nut

7. Blade bolt

8. Cutting blade (7 used)

9. Anti--scalp cup

10. High driven spindle (1 used)

11. Flat washer

12. Cap screw

Figure 13

4

3

1

10

11

12

88 to 108 ft--lb

(119 to 146 N--m)

2

FRONT

RIGHT

5

7

6

9

8

Removal (Fig. 13)

1. Park machine on a level surface,lowercuttingdeck,

stop engine, engage parking brake and remove key

from the ignition switch.

2. If drive spindle is to be serviced, remove hydraulic

motor from cutting deck (see Cutting Deck Motor Re-

moval in the Service and Repairs Section of Chapter 4

-- HydraulicSystem). Positionmotoraway fromspindle.

3. Removebeltcoversfromtopofcuttingdeck.Loosen

idler pulley to release belt tension (see Idler Assembly

Removalinthissection).Removedrivebeltfromspindle

to be serviced.

4. Start theengine and raise the cutting deck. Stop en-

gine and remove key from the ignition switch. Latch or

block up the cutting deck so it cannot fall accidentally.

5. Removecuttingblade,anti--scalpcupandbladebolt

from spindle to be serviced.

6. Remove spindle housing assembly from deck:

A. For driven s pindle assemblies, remove eight (8)

flange head screws w ith flange nuts that secure

spindle to deck.

B. Fordrivespindleassemblies,loosenandremove

four (4) flange head screws with flange nuts that se-

cure spindle to deck. Then, remove four (4) cap

screwswithflatwashersthatsecurespindleandmo-

tor mount to deck.

Loading...

Loading...