FuelSystem

Maintenance

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

RefertoFuelSafety(page17)foracomplete

listoffuelrelatedprecautions.

ServicingtheElectronic

Fuel-InjectionSystem

Thismachinecontainsanelectronicfuel-injection

system.Itcontrolsthefuelowunderdifferent

operatingconditions.

Theelectronic-controlunit(ECU)continuously

monitorstheoperationoftheEFIsystem.

Ifaproblemorfaultwithinthesystemisdetected,the

LEDstatuslightilluminates.TheMIListheredlight

locatedontherightsideofthehourmeter.

Oncethelightilluminates,makeinitialtroubleshooting

checks;refertotheLEDstatuslightsectionunder

Troubleshooting(page70).

Ifthesechecksdonotcorrecttheproblem,further

diagnosisandservicingbyanAuthorizedService

Dealerisnecessary.

ReplacingtheFuelFilter

ServiceInterval:Every400hoursoryearly,

whichevercomesrst

Thefuellterislocatedneartheengineonthefront

orrearsideoftheengine.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Waitforthemachinetocooldown.

4.Closethefuel-shutoffvalveundertheseat

(Figure52).

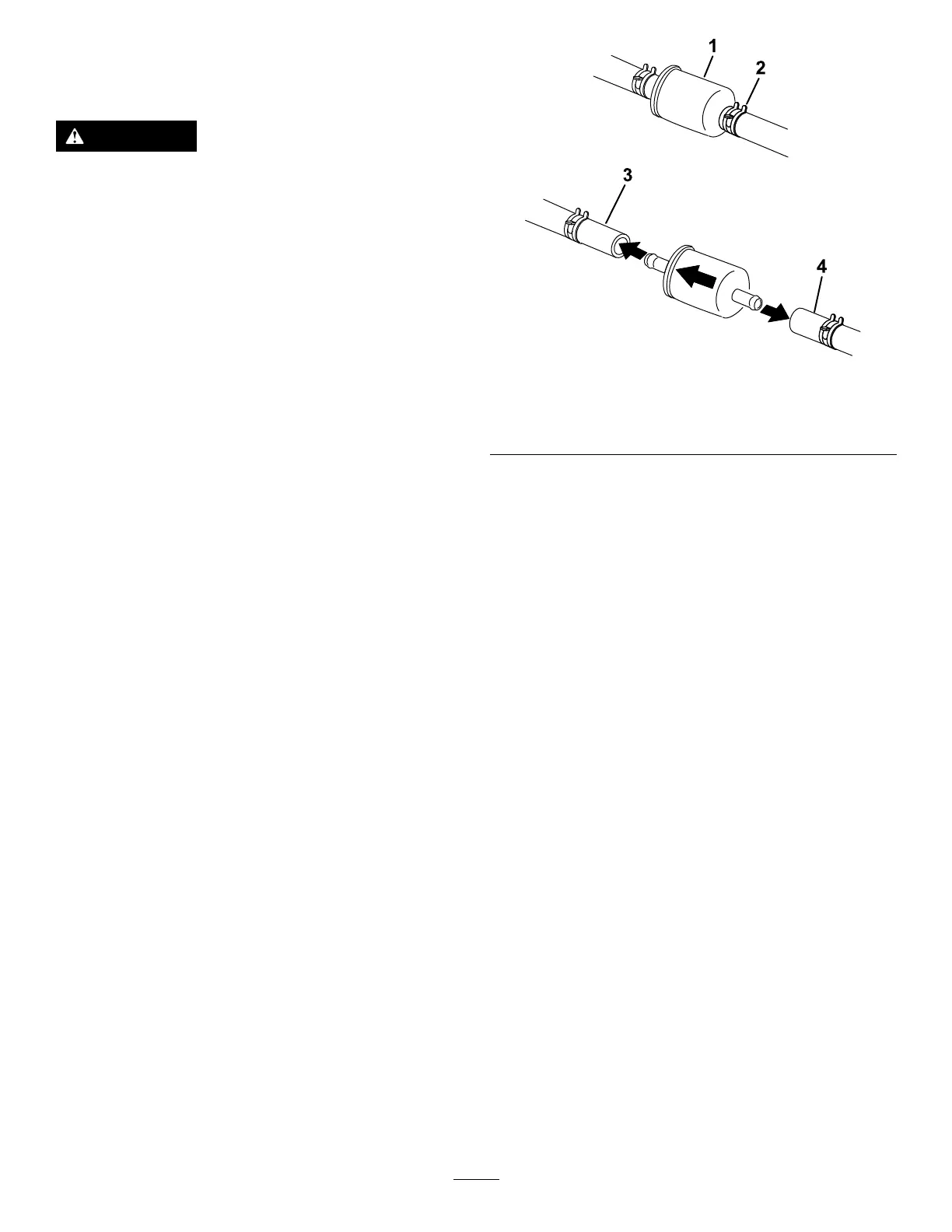

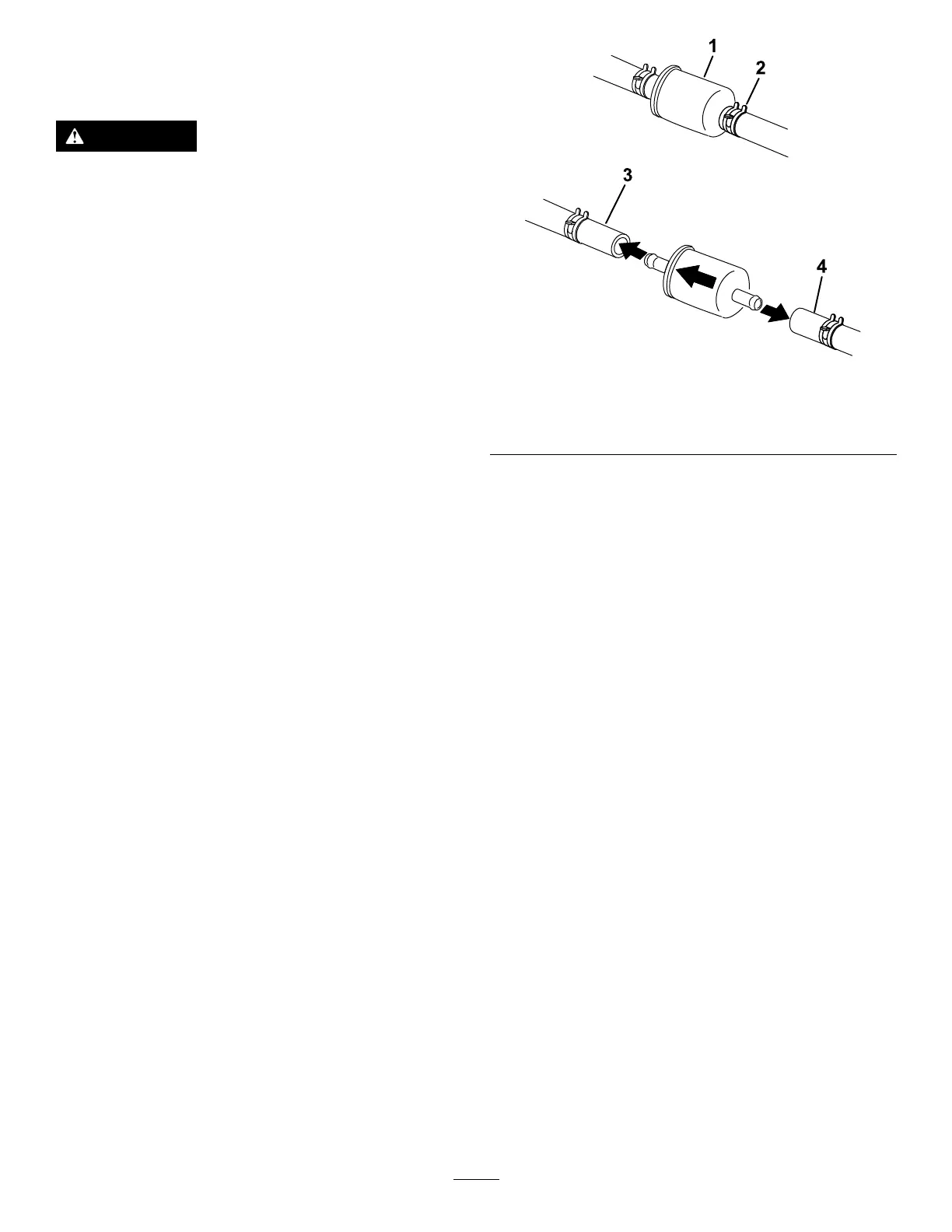

g333362

Figure52

1.Fuellter

3.Fuellinetotheengine

2.Hoseclamp

4.Fuellinefromthefueltank

5.Squeezetheendsofthehoseclampstogether

andslidethemawayfromthelter(Figure52).

6.Removethelterfromthefuellines.

7.Installanewlterandmovethehoseclamps

closetothelter(Figure52).

8.Openthefuel-shutoffvalve.

Important:Installthefuellinehosesandsecure

withplastictiesthesameastheywereoriginally

installedatthefactorytokeepthefuellineaway

fromcomponentsthatcancausefuellinedamage.

ServicingtheFuelTank

Donotattempttodrainthefueltank.Ensurethatan

AuthorizedServiceDealerdrainsthefueltankand

servicesanycomponentsofthefuelsystem.

44

Loading...

Loading...