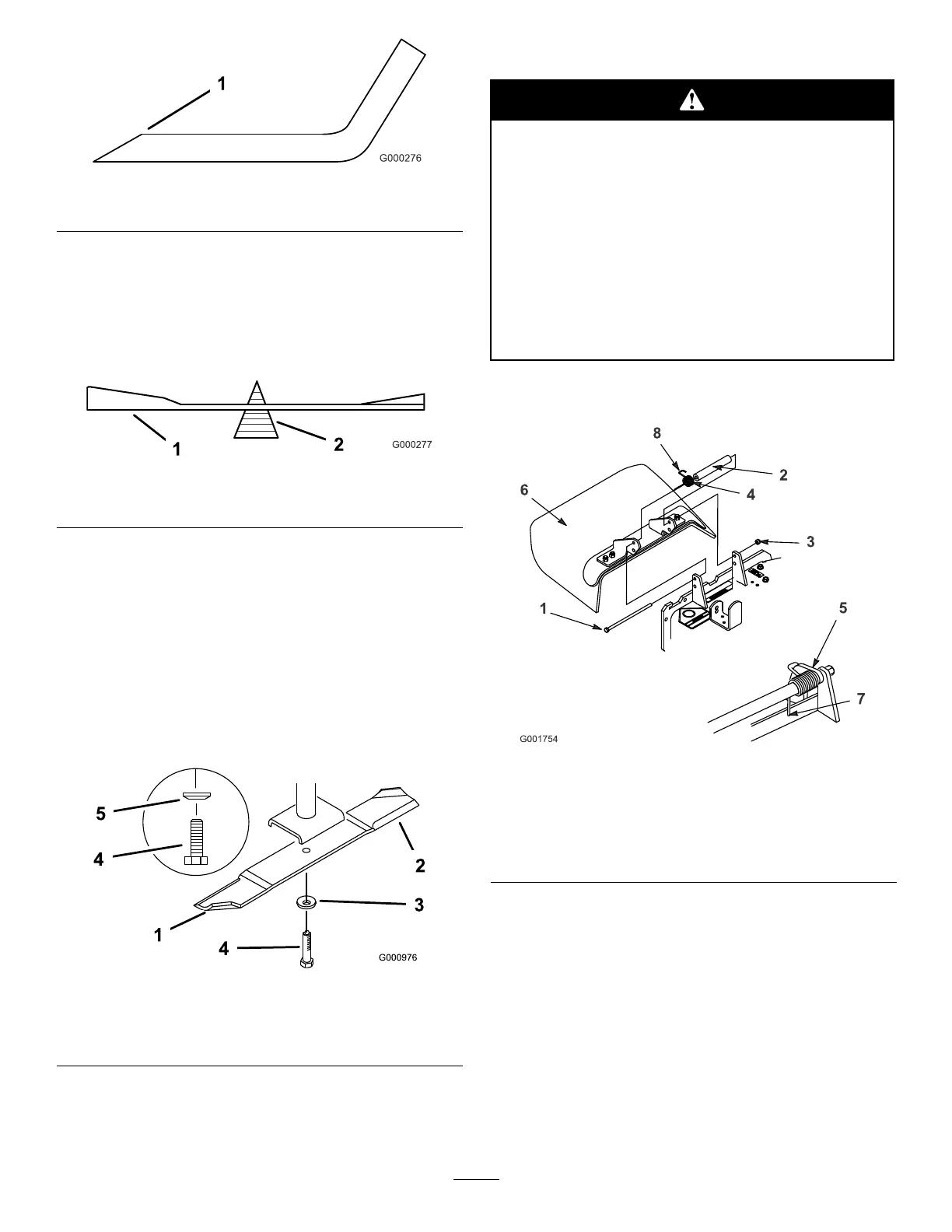

Figure64

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitona

bladebalancer(Figure65).Ifthebladestaysina

horizontalposition,thebladeisbalancedandcanbe

used.Ifthebladeisnotbalanced,lesomemetaloff

theendofthesailareaonly(Figure66).Repeatthis

procedureuntilthebladeisbalanced.

Figure65

1.Blade2.Balancer

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure66).

Important:Thecurvedpartoftheblademust

bepointingupwardtowardtheinsideofthe

mowertoensurepropercutting.

2.Installthespringdiskandbladebolt.Thespring

diskconemustbeinstalledtowardthebolthead

(Figure66).

Figure66

1.SailAreaofBlade

4.BladeBolt

2.Blade

5.ConeTowardsBoltHead

3.SpringDisk

3.Torquethebladeboltto85-110ft-lb(115-150N⋅m).

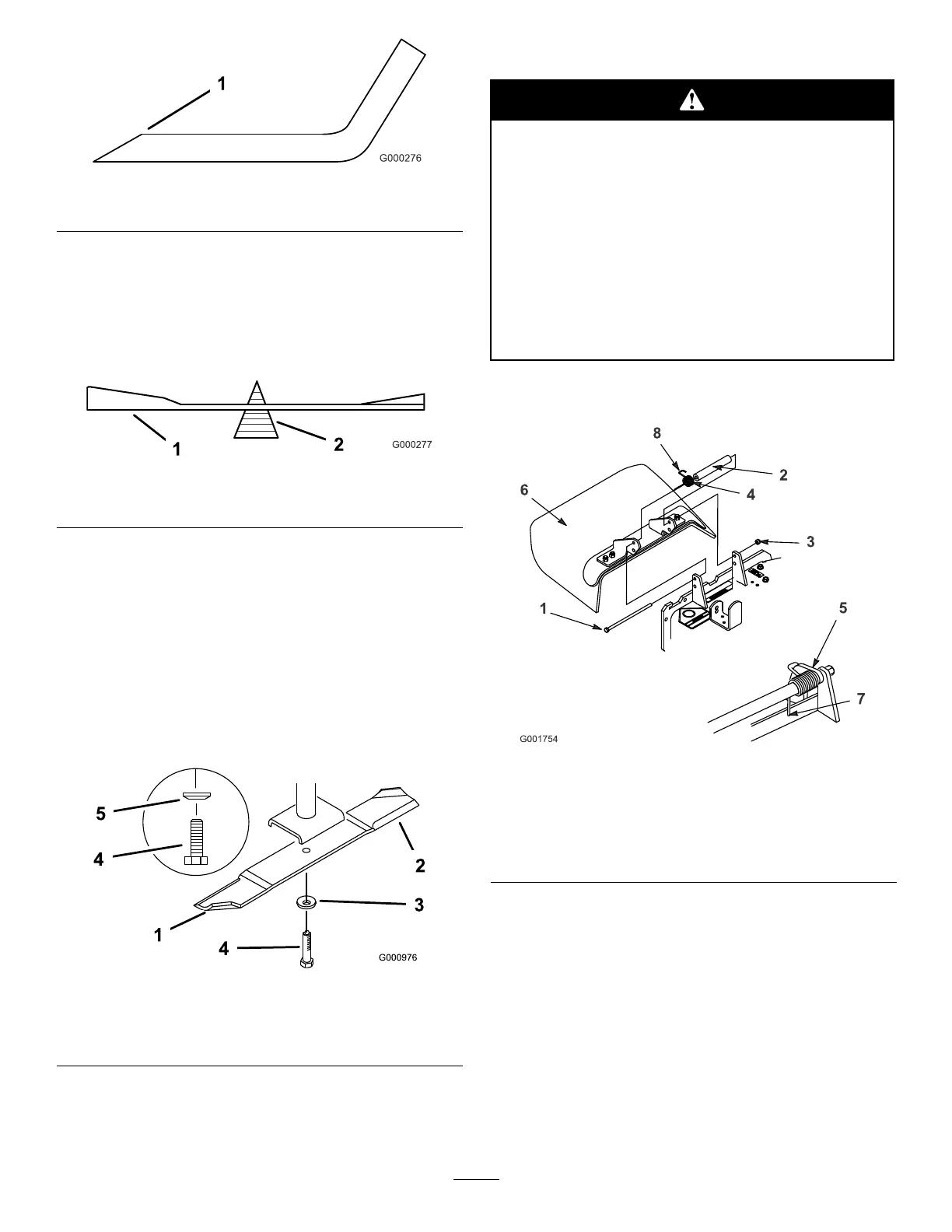

ReplacingtheGrassDeector

Anuncovereddischargeopeningcouldallow

thelawnmowertothrowobjectsinthe

operator’sorbystander’sdirectionandresult

inseriousinjury.Also,contactwiththeblade

couldoccur.

•Neveroperatethelawnmowerunlessyou

installacoverplate,amulchplate,oragrass

chuteandcatcher.

•Makesurethegrassdeectorisinthedown

position.

1.Removethelocknut,bolt,springandspacerholding

thedeectortothepivotbrackets(Figure67).

Figure67

1.Bolt

5.Springinstalled

2.Spacer6.GrassDeector

3.Locknut7.Placebehinddeckedge

beforeinstallingbolt

4.Spring8.Hookendofspring

2.Removethedamagedorworngrassdeector.

3.Installtheboltandnut.

4.PlacetheJhookendofthespringaroundthegrass

deector(Figure67).

Important:Thegrassdeectormustbeableto

lowerdownintoposition.Liftthedeectorup

totestthatitlowersintothefulldownposition.

47

Loading...

Loading...