HydraulicSystem

Maintenance

Thereservoirislledatthefactorywithapproximately

4.7liters(5quarts)ofhighqualitytractor

transmission/hydraulicuid.Therecommended

replacementuidisasfollows:

ToroPremiumTransmission/HydraulicTractorFluid

(Availablein5gallonpailsor55gallondrums.Seeparts

catalogorauthorizedT orodistributorforpartnumbers.)

Alternateuids:IftheT orouidisnotavailable,

Mobil®424hydraulicuidmaybeused.

Note:T orodoesnotassumeresponsibilityfor

damagecausedbyimpropersubstitutions.

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditivefor

thehydraulicsystemoilisavailablein20ml(0.67oz)

bottles.Onebottleissufcientfor15to22L(4to6

USgallons)ofhydraulicuid.OrderPartNo.44-2500

fromyourauthorizedTorodistributor.

HydraulicSystemSafety

•Seekimmediatemedicalattentionifuidisinjected

intoskin.Injecteduidmustbesurgicallyremoved

withinafewhoursbyadoctor.

•Ensurethatallhydraulic-uidhosesandlinesare

ingoodconditionandallhydraulicconnections

andttingsaretightbeforeapplyingpressureto

thehydraulicsystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthigh-pressurehydraulic

uid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

CheckingtheHydraulic

System

ServiceInterval:Beforeeachuseordaily

Checkthelevelofthehydraulicuidbeforeyourst

starttheengineanddailythereafter.

1.Positionthemachineonalevelsurface.

2.Movethemotion-controlleverstothe

NEUTRAL-LOCKpositionandstarttheengine.

Note:Runtheengineatthelowestpossible

rpmtopurgethesystemofair.

Important:DonotengagethePTO.

3.Raisethedecktoextendtheliftcylinders,shut

offtheengine,andremovethekey.

4.Raisetheseattoaccessthehydraulicuidtank.

5.Removethehydraulicllcapfromthellerneck

(Figure92).

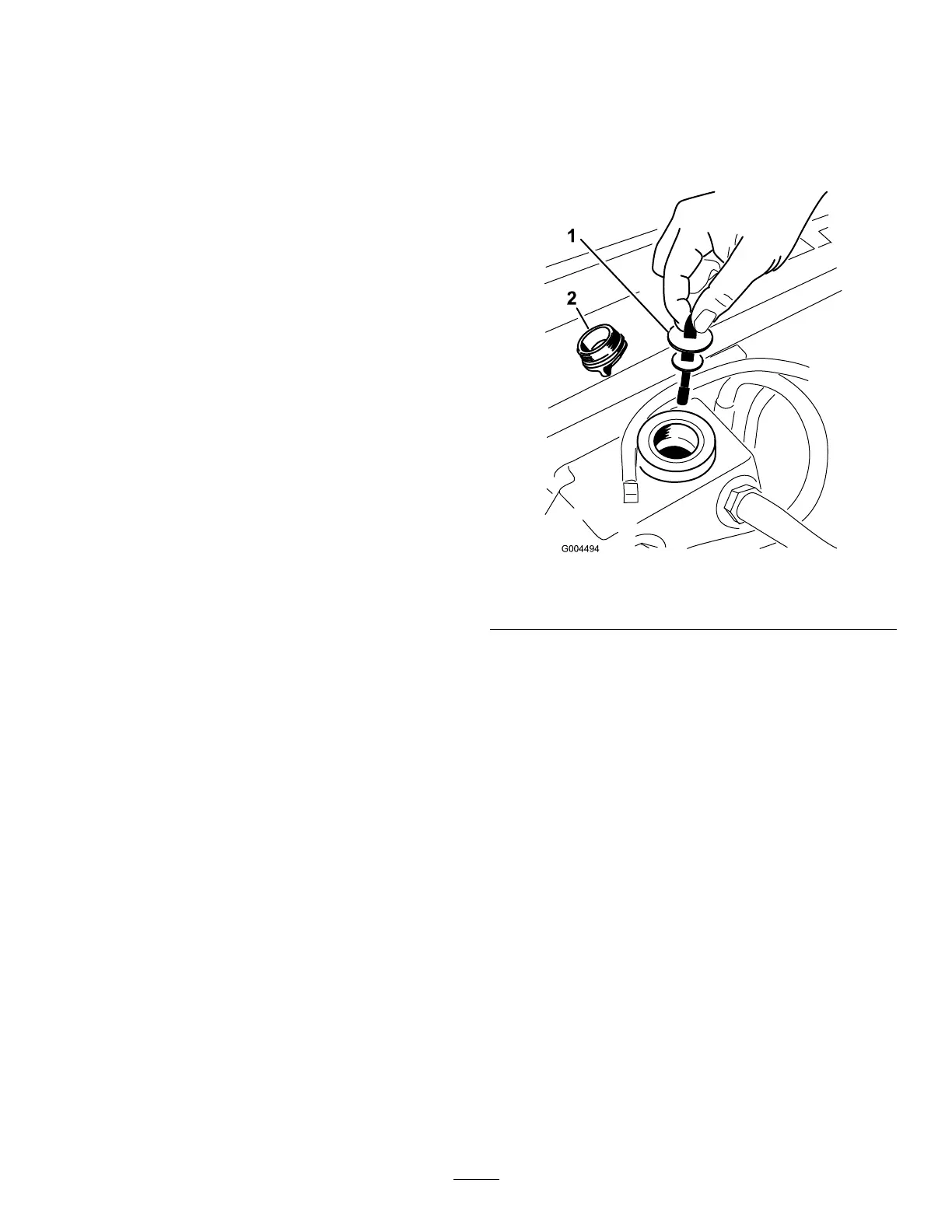

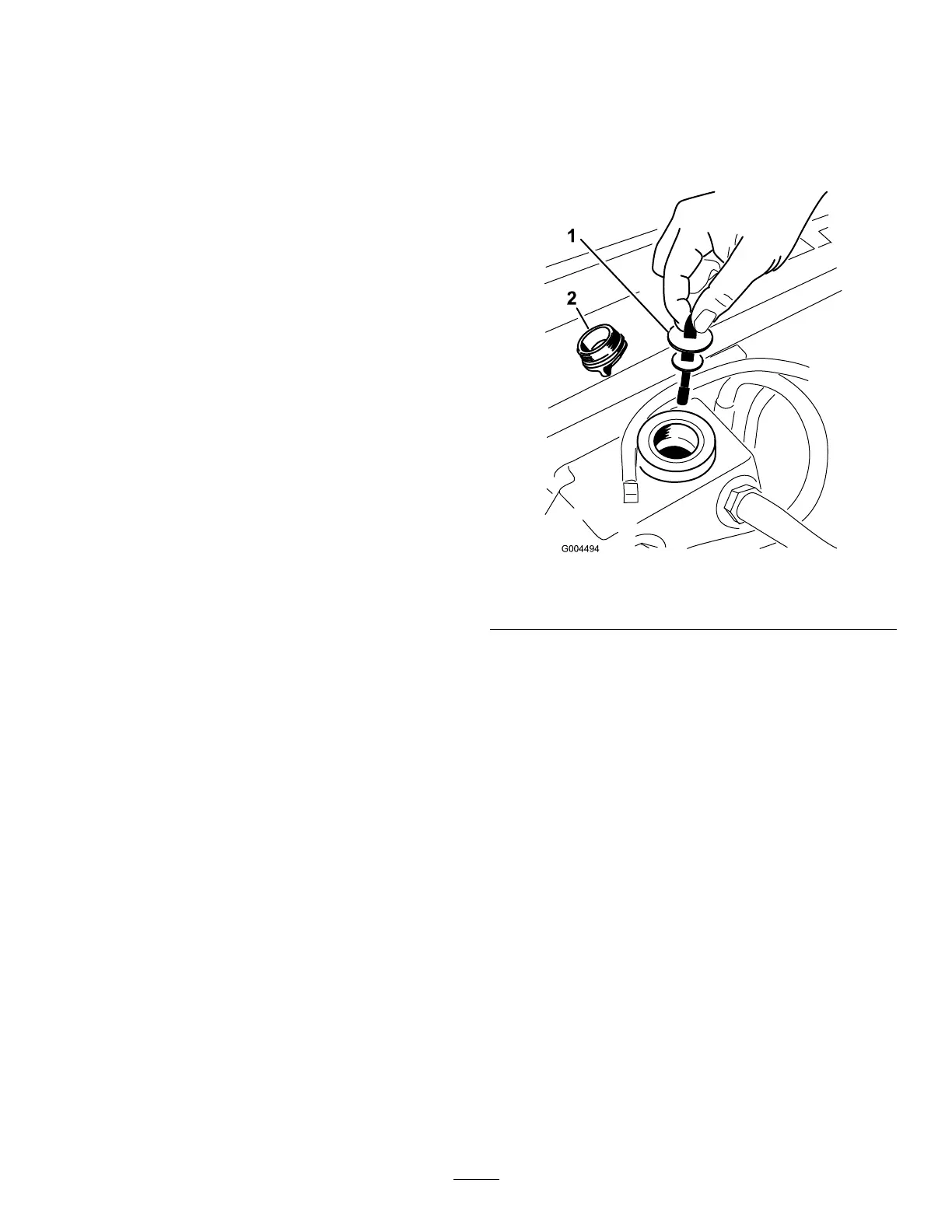

g004494

Figure92

1.Dipstick2.Fillcap

6.Removethedipstickandwipeitwithacleanrag

(Figure92).

7.Placethedipstickintothellerneck;then

removeitandcheckthelevelofuid(Figure92).

Note:Ifthelevelisnotwithinthenotchedarea

ofthedipstick,addenoughhigh-qualityhydraulic

uidtoraisetheleveltowithinthenotchedarea.

Important:Donotoverll.

8.Replacethedipstickandthreadthellcap

nger-tightontothellerneck.

9.Checkallhosesandttingsforleaks.

61

Loading...

Loading...